Siemens Desigo TRA QMX3.P36F User manual

Other Siemens Controllers manuals

Siemens

Siemens SIPROTEC 5 User manual

Siemens

Siemens SIMATIC ET 200SP User guide

Siemens

Siemens Simatic S7-400 Quick guide

Siemens

Siemens SIMATIC S7-1200 User manual

Siemens

Siemens 353 User manual

Siemens

Siemens RUGGEDCOM WIN5214 User manual

Siemens

Siemens BT300 LonWorks User guide

Siemens

Siemens ATC5300 Mounting instructions

Siemens

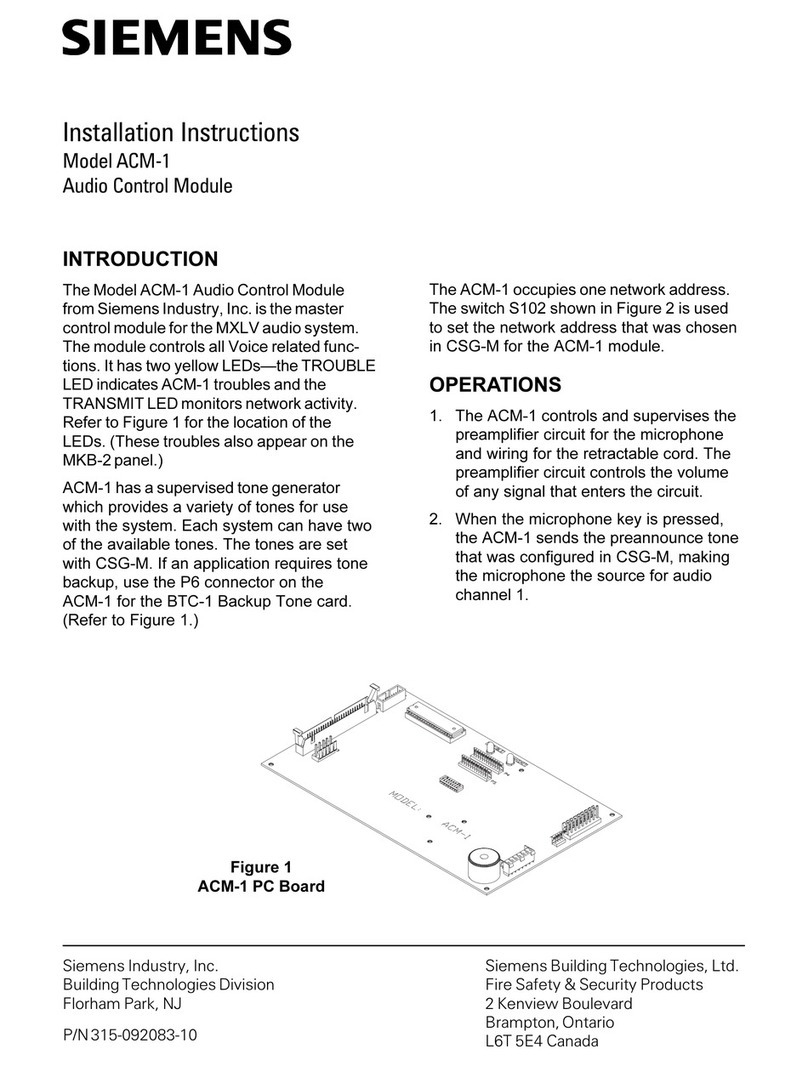

Siemens ACM-1 User manual

Siemens

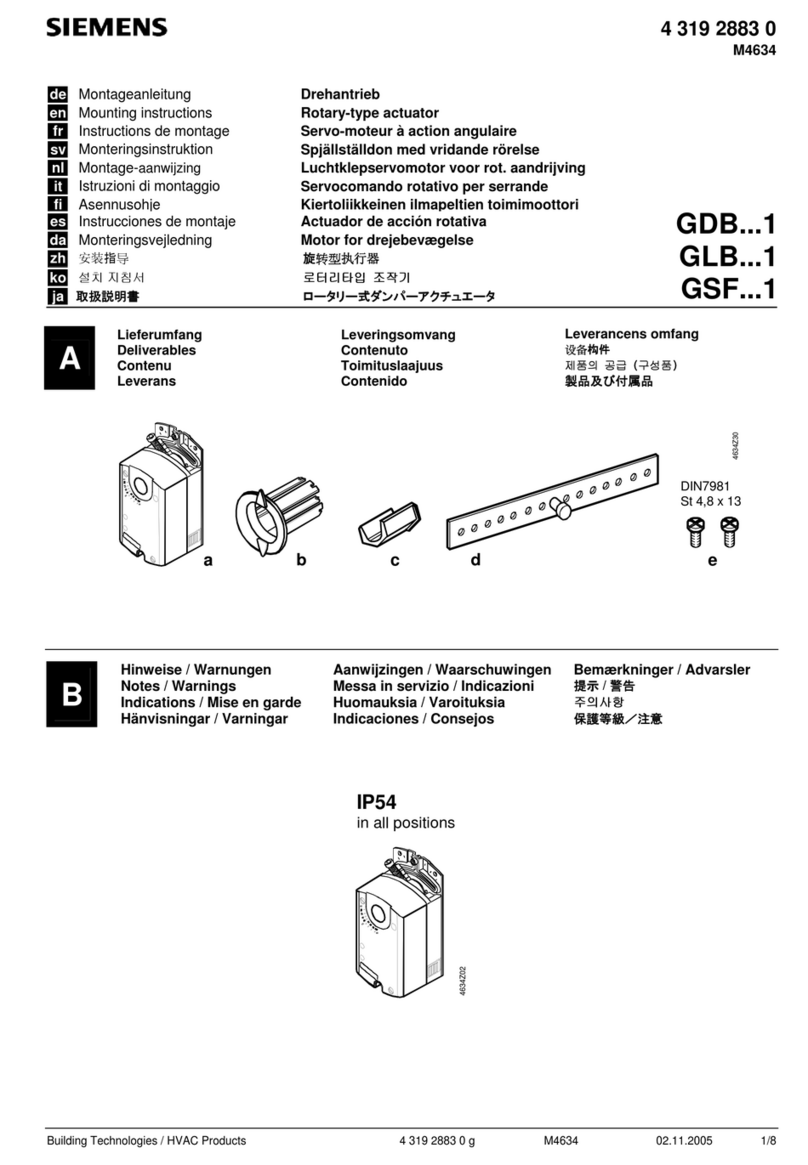

Siemens GDB 1 Series User manual

Siemens

Siemens 7sg15 microtapp User manual

Siemens

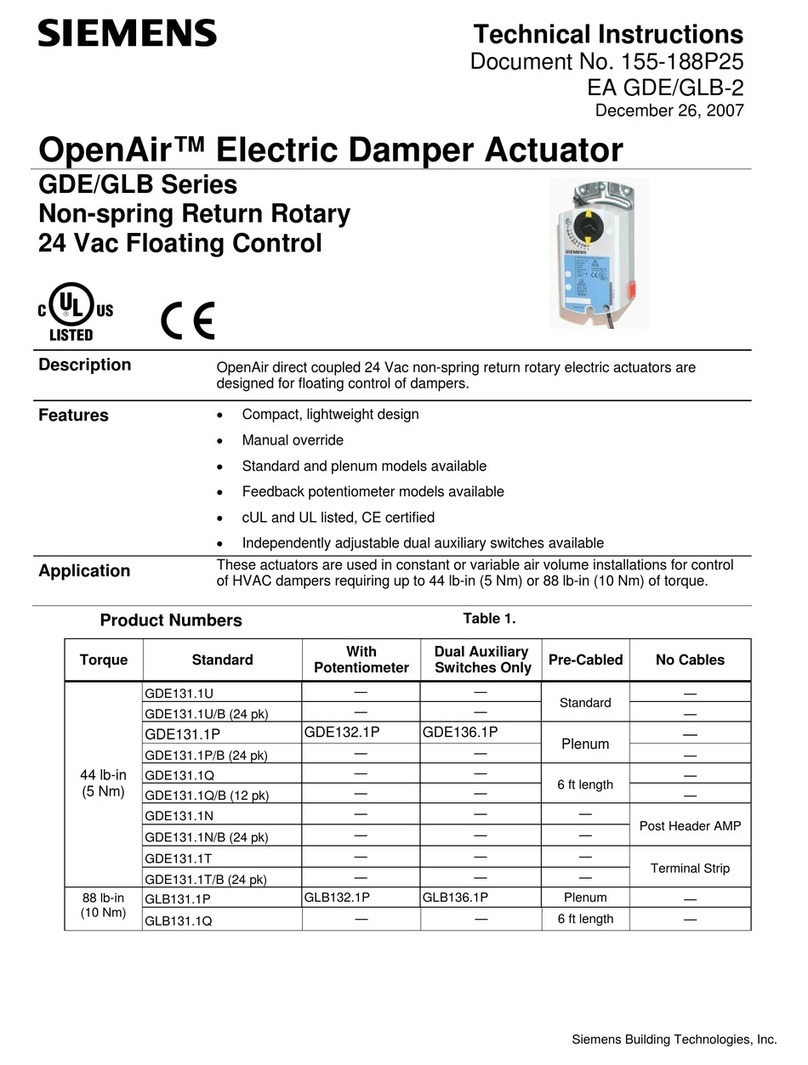

Siemens OpenAir GSD 1 Series User manual

Siemens

Siemens SIRIUS Series User guide

Siemens

Siemens GXD 31.1 Series User manual

Siemens

Siemens SIRIUS 3RW44 User guide

Siemens

Siemens Powermite 599 Series Owner's manual

Siemens

Siemens SSA955 User manual

Siemens

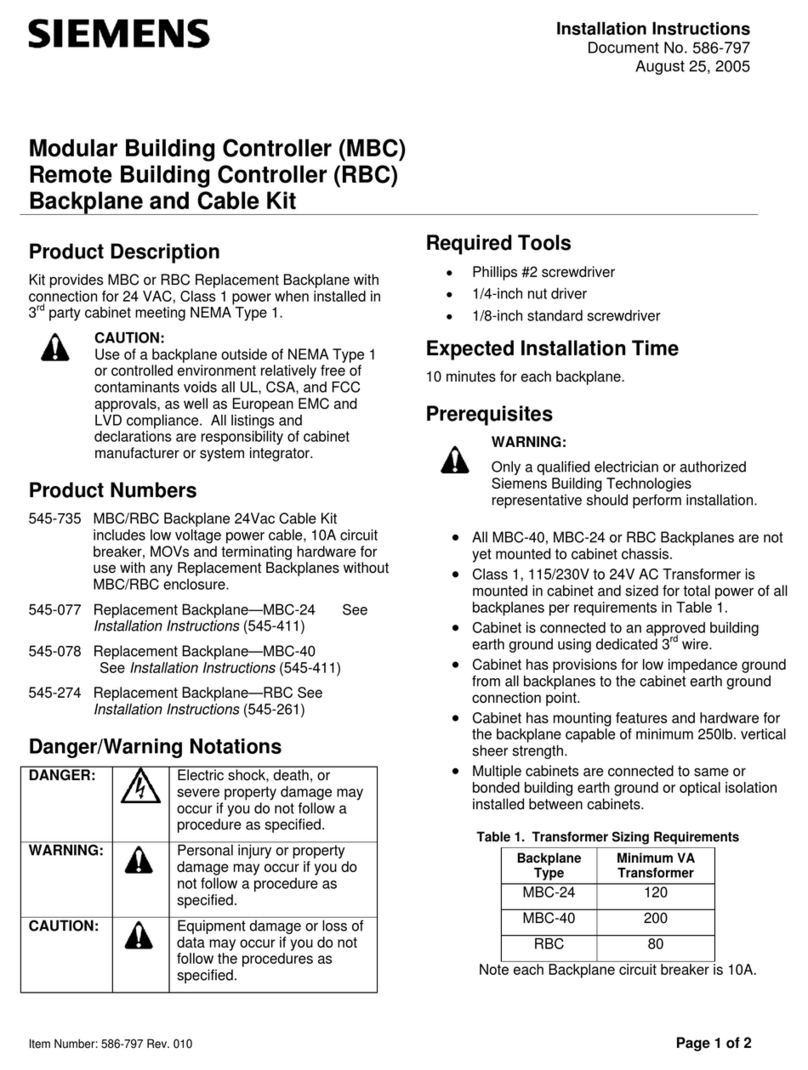

Siemens RBC User manual

Siemens

Siemens RVS41.813 User manual

Siemens

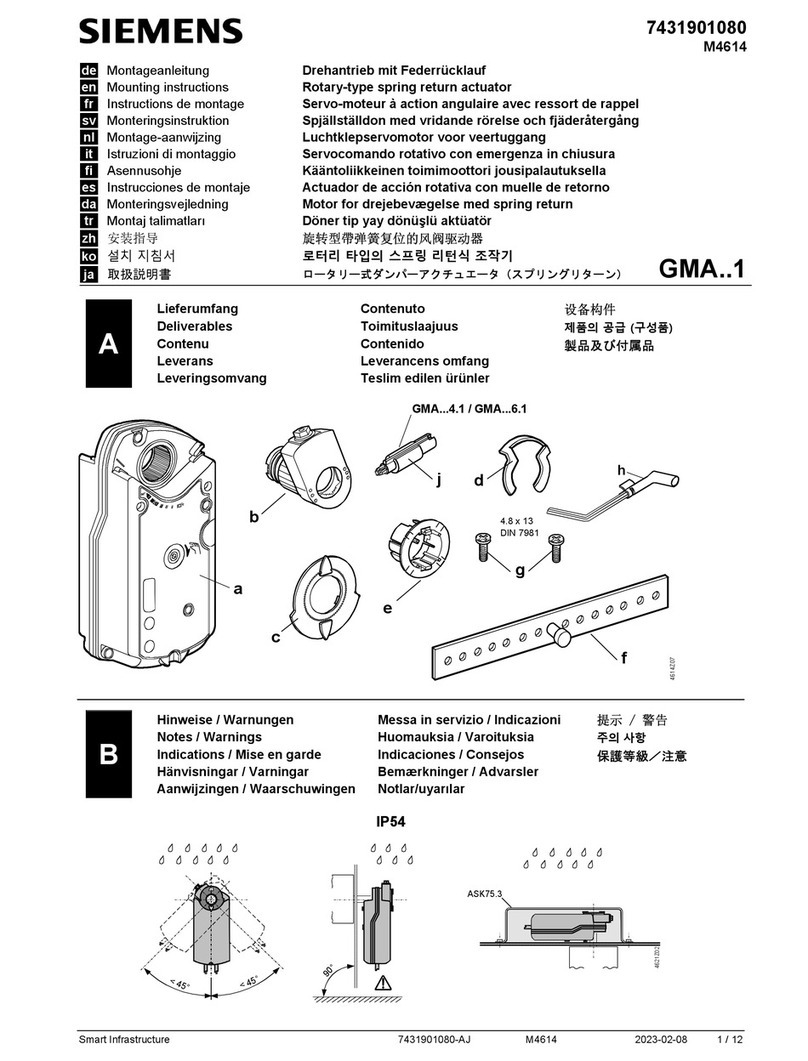

Siemens OpenAir GMA 1 Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions