3/15

Building Technologies Division CC1N7418en

21.06.2016

Installation notes

Always run the high-voltage ignition cables separate from the unit and other cables

while observing the greatest possible distances

Make absolutely certain that life and neutral conductors are correctly connected to

terminals 1 and 2 of the burner control; otherwise, no flame signal will be generated

Ensure that the maximum permissible current load for the connecting terminals is

not exceeded (refer to Technical data)

Install switches, fuses, earthing, etc., in compliance with local regulations

The connection diagrams shown apply to burner controls with earthed neutral

conductor. In the case of ionization current supervision in networks with

nonearthed neutral conductor, terminal 2 must be connected to the earth conductor

via an RC unit (part no. ARC 4 668 9066 0). In that case, it must be made certain

that the relevant national safety regulations are complied with (e.g. electric shock

hazard protection), since AC 230 V / 50 Hz mains voltage results in a leakage

current of 2.7 mA

Make certain that the maximum permissible current rating of the connection

terminals will not be exceeded

Do not feed external mains voltage to the control outputs of the unit. When testing

the devices controlled by the burner control (fuel valves, etc.), the LGA… must not

be connected

To isolate the burner control from the mains supply, use an all-polar switch with a

contact gap of at least 3 mm

Secure the earthing lug in the terminal base with a metric screw and a lockwasher

or similar

Switches, fuses, earthing, etc., must be in compliance with local regulations;

primary fuse max. 10 A slow

Connect the gas pressure switch and controller, whose contacts must be closed

from startup to controlled shutdown, in series with control thermostat or

pressurestat (R) and limit thermostat or pressure switch (W)

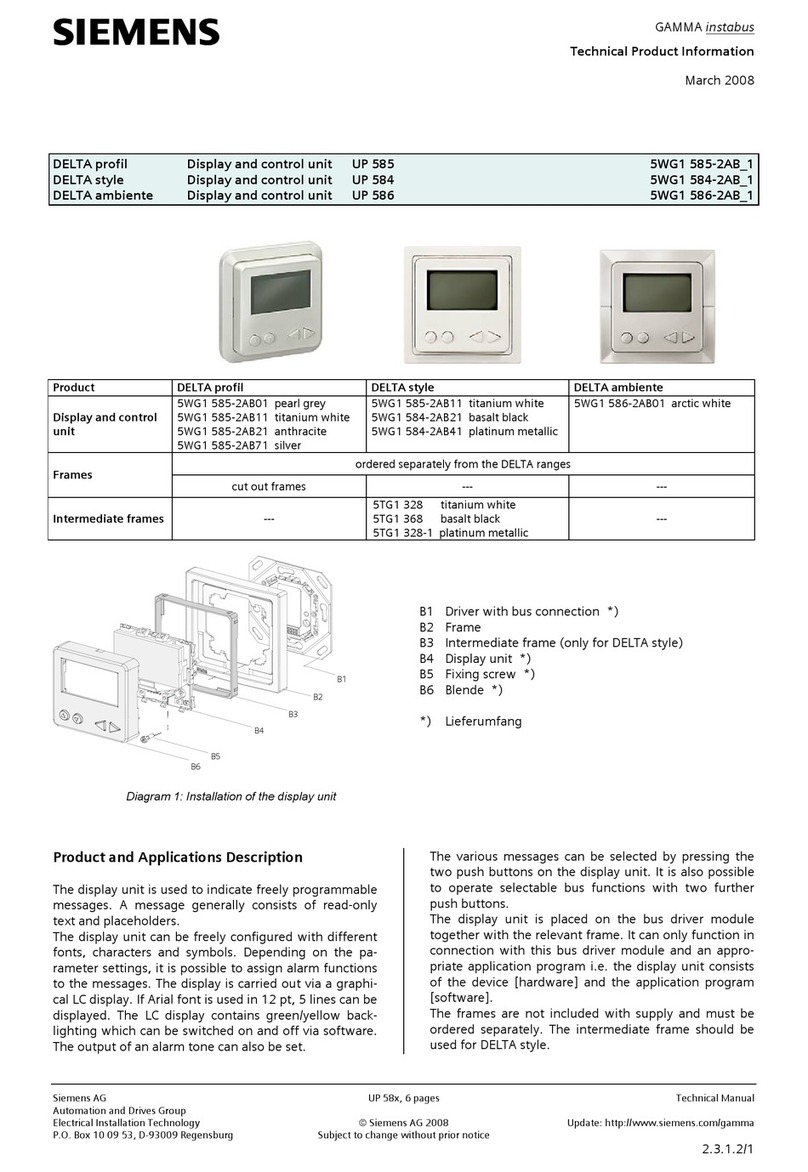

For safety reasons, feed the neutral conductor to the neutral distributor in the plug-

in base, or to terminal 2. Connect the burner components (fan, ignition transformer

and gas valves) as represented in the figure 7435a14, to the neutral distributor as

shown below. The connection between neutral conductor and terminal 2 is

prewired in the terminal base

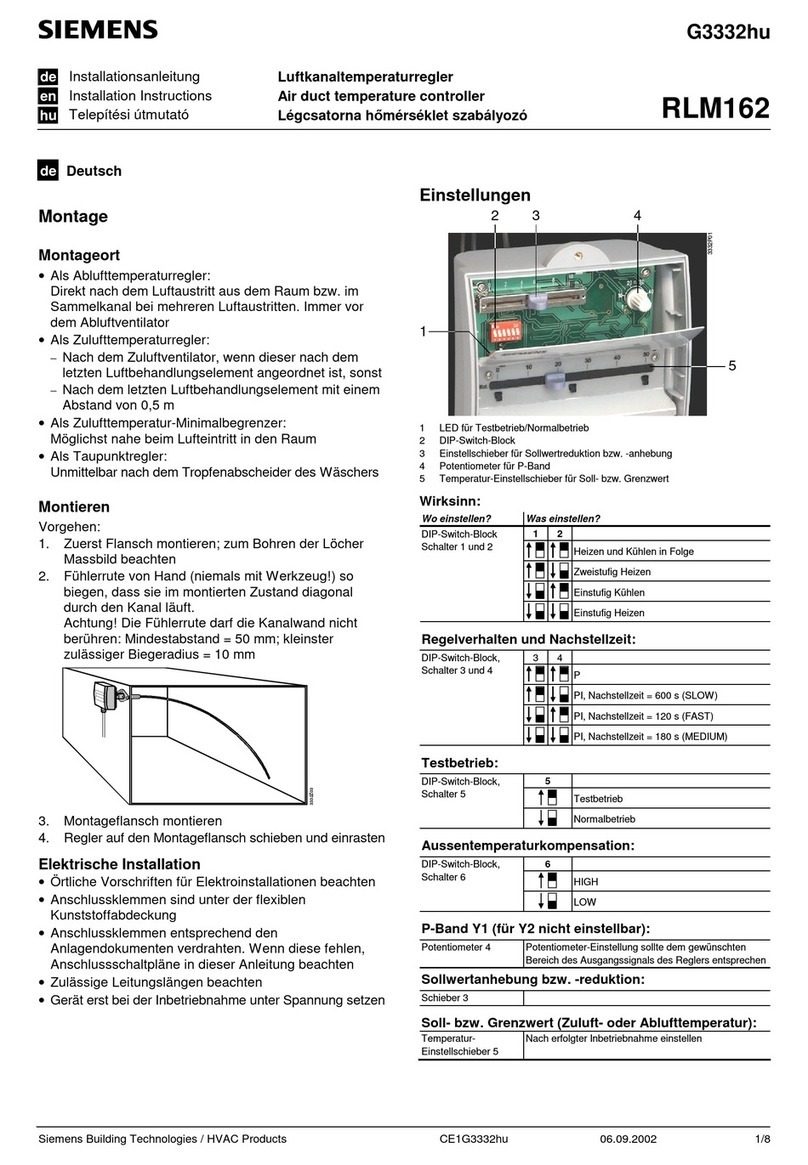

Example

237 4 5

M

N

7435a14/0601

ZV1

V2

Key

V... Fuel valve

M fan motor

Z ignition transformer

Correct wiring of neutral conductors!

If the fully closed position of the main valve «BV2» shall be checked on burner

startup, the closed position contact must be included in the loop between terminals

9 and 3. In addition, the connecting links between terminals 9 and 11 and 8 and 3

must be fitted

During the startup sequence, terminal 6 carries voltage and must not be used as

an auxiliary terminal

The auxiliary contact of a gas valve for checking the fully closed position must be

included in the loop between terminals 9 and 3

During the startup sequence, terminals 9 and 6 carry voltage and must not be used

as auxiliary terminals

Connect the load controller of 2-stage burners to terminal 5 in series with «BV2»

Only with LGA41...

Only with LGA52... /

LGA63...