Installation:

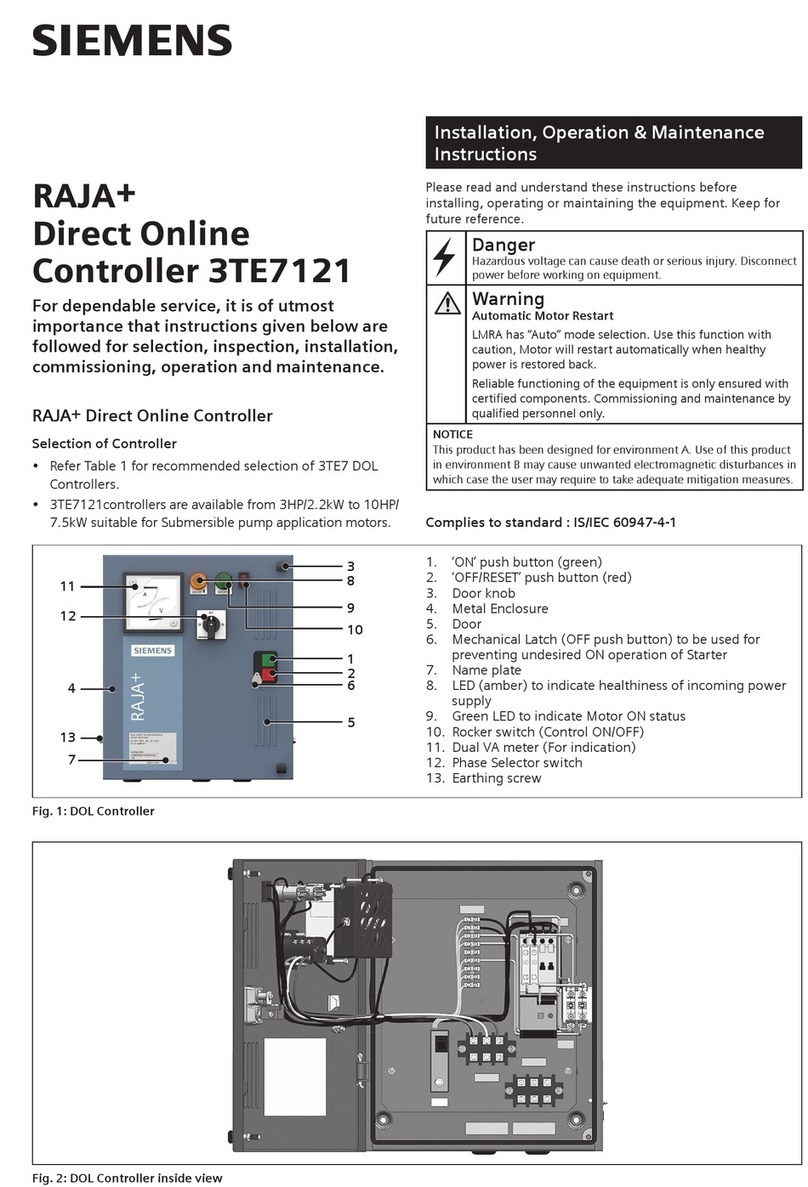

• Openthedoorbyunscrewingthedoorknob.

• Mountthecontrolleronaverticalwall/platefreefrom

vibrationswithpropernutsandbolts.ReferFig.5for

mountingdimensions.

• Removetherubbergrommetsfortheincomingand

outgoingcableconnections.(ReferFig.2).

• Connectincomingandoutgoingcablesasfollows

(ReferFig.2):

– Usepropercableglandstoensuredustproong.For

conduitentryusepackedwashers.

– SelectcorrectsizeofcablesfromTable1.

– Removeapprox.lengthofinsulationasperfollowing

table:

Lengthofinsulation

removal(mm)

Cucablesize

(mm2)

62.5

5 1.5

– Connectlineandmotorcablesexactlyasperwiring

diagrampastedinsidethecoverofthestarter.

– Terminatetheincomingsupplycablesonterminal

blockTB1&outgoingcablestomotoronterminal

blockTB2(Tighteningtorque-Refertable2).

NOTE:LMRAissetinManualmode(Factorysetting)

WLCissetinDeliverymode(Factorysetting)

• Settheoverloadrelayscale(Fig.2)usingproperscrew

driverasfollows:

– Settheoverloadrelaytoratedcurrentmentionedon

motornameplate.

– PressgreenbuttonofthecontactblockCB1(Fig.2)

tostartthemotorandwaittillitreachestonormal

speed.Reducetheoverloadrelaysettingstillittrips.

– Settheoverloadrelayatslightlyhighervalue.

– Allowaresettimeappr.4min.andresettheoverload

relaymanually.

– Restartthemotor.Iftherelaydoesnottrip,consider

theoverloadrelayasproperlyset.

Ifittrips,setitatlittlehighervalueandrecheck.

– Presstheredknob(Fig.2)ontheoverloadrelayto

stopthemotor.

– Closethedoorbyscrewingthedoorknob.

Procedure for connecting WLC sensors & terminations:

• ThesesensorsneedtoberoutedfromleftsideofBase

platethroughcablegland(Pleaseensureduecareto

avoiddamagetothesensors.)

Caution:

• During commissioning or maintenance always ensure

that the main supply is disconnected by switching off

the main switch & Rocker switch.

• Iftherelaytripsevenwhensetatratedmotorcurrent

thesuitabilityofthecontroller/relayfortheparticular

applicationshouldbecheckedwiththenearestSiemens

office.

Operation:

• Ensurethedoorislocked.

• RotatetheMechanicalLatchawayfromOFFpushbutton.

• SwitchOntherockerswitchmarked‘I’.

• CheckthestatusofamberLED.WaittillamberLEDis

continuouslyONthenonlyproceed.

• DependinguponSelectorswitchknobpositionforphase

selection,Indicationofincomingpowersupplyvoltage

canbeseenonDualVAmeter.

• Forstartingthemotor,pressGreenpushbuttonmarked

‘I’(Fig.1).

• LinecurrentofRphaseisindicatedbyDualVAmeter.

• MotorisONwhengreenLEDisON.

• ForstoppingthemotorpressRedpushbuttonmarked‘O’

(Fig.1).

• ForLMRAAuto/Bypassmodes,refertroubleshooting

guideA5E50797230A.

• ForWLCDelivery/Suction/Dualtankmodes,refer

troubleshootingguideA5E50797230A.

• ResetOperation

– Iftheoverloadrelaytrips,Resetmanually.(Allowa

resettimeofapprox.4min.)

Maintenance:

• SwitchofftheControllerandPutLatchontheOFFpush

button,(marked‘O’).Disconnect the main supply by

switching the main switch & Rocker Switch Off before

doing any maintenance.

• Keeptheinteriordustfree.

• Re-tightentheterminalscrewsfromtimetotimeasper

speciedtorqueintable2.

• Nomaintenanceisneededforoverloadrelay.Pleasedo

notopentherelay.

• Replacecontactsofthecontactoriftheywereseverely

pittedorwhenonly40%oftheoriginalcontacttips

remains.

• ReplacementofOverloadRelay(ReferFig.3):

1. Selectaproperrelayexactlyaspertheoriginal.

2. Slightlyloosentheoutgoingterminalscrewsofthe

relay.

3. Disconnectthewiresconnectedtotherelayterminals.

4. Slightlyloosentheoutgoingterminalscrewsofthe

contactor.

Mode For Single Tank application

(Delivery or Suction mode)

For Dual Tank application

(Dual tank mode) For by passing WLC

ConnectionProcedure ConnectsensorsP1,P2&

P3toTerminalX1,X2,X3of

TerminalblockTB5

ConnectsensorsP1,P2

&P3toTerminalX1,X2,

X3ofTerminalblockTB5

&sensorsP4,P5&P6to

TerminalX4,X5,X6of

TerminalblockTB5

Removeconnection

betweenX7-X8ofTerminal

blockTB5.

Removeconnectionfrom

X11ofTB5&Connectitto

X12ofTB5.

2