Technical Instructions

Document No. 155-516P25

Rev. 2, December, 1998

P

PP

Pa

aa

age

gege

ge 4

44

4

o

oo

of

ff

f 9

99

9 Siemens Building Technologies, Inc.

Landis Division

O

OO

Op

pp

pe

ee

er

rr

ra

aa

at

tt

ti

ii

io

oo

on

nn

n

(

((

(

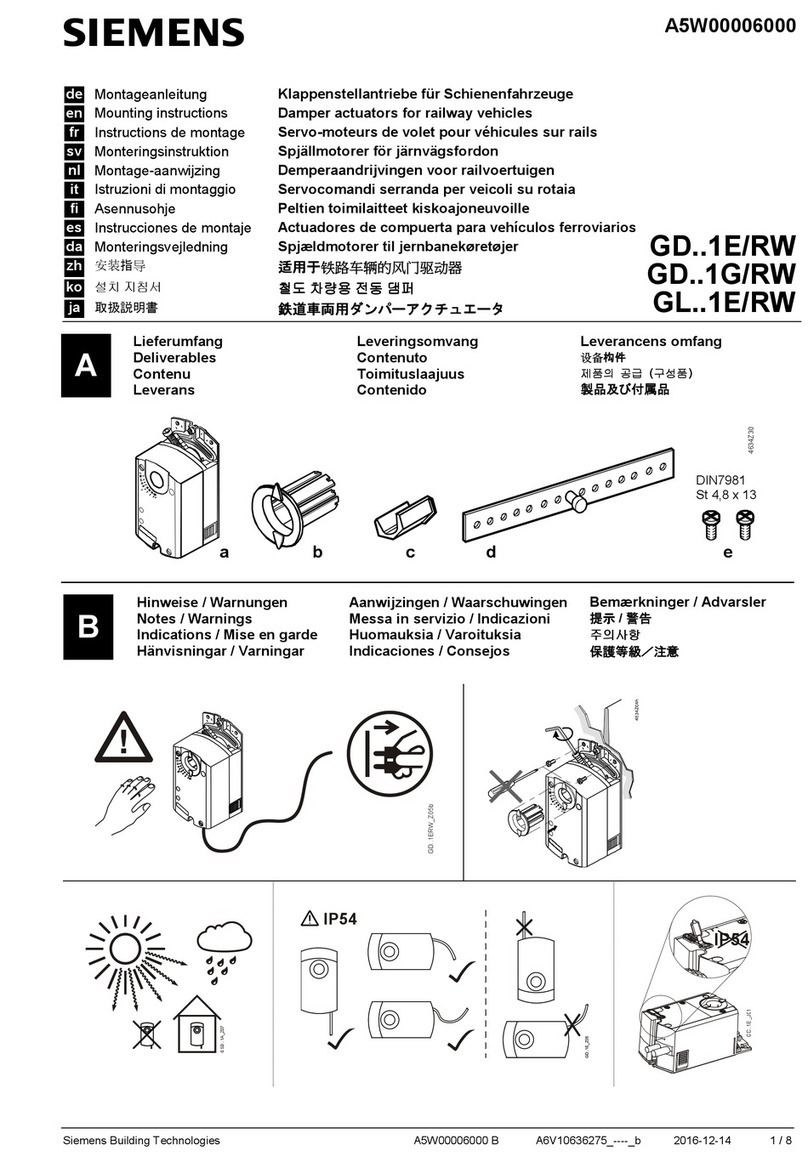

S

SS

See

eeee

ee

Fi

FiFi

Fig

gg

gur

urur

ure

ee

e 1

11

1)

))

)

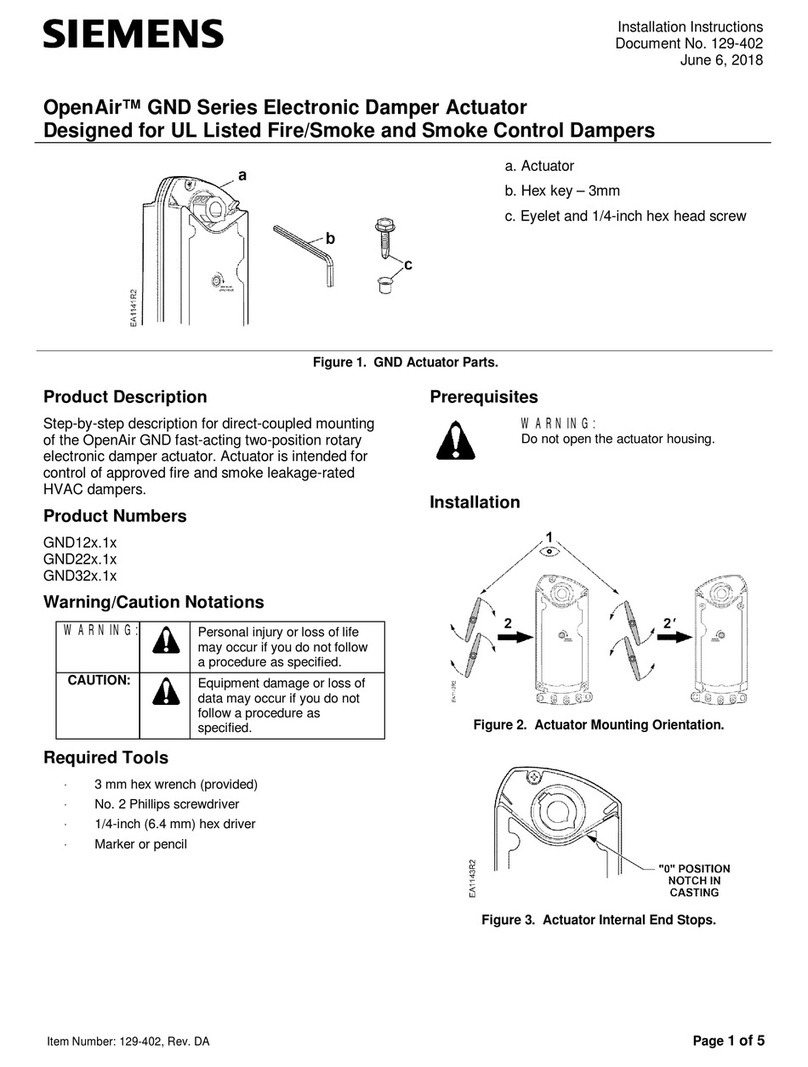

Safety Shutoff Function The electro-hydraulic actuator consists of a cylinder filled with oil and a piston

containing an electric oscillating pump and a hydraulic relief system. When power is

supplied to the actuator, the pump located at the base of the piston moves oil from the

reservoir (through an orifice) into the pressure chamber. The oil flow from the pump

through the orifice creates a pressure difference moving the diaphragm and the

attached spring loaded plug to the left, closing the return flow path from the pressure

chamber to the reservoir. This action causes the piston to move downward in the

cylinder opening the gas valve. When power to the pump is interrupted, the pressure

difference across the orifice instantly reduces to zero. The plug is immediately pushed

to the right allowing the oil to flow back from the pressure chamber into the reservoir,

closing the valve in less than 0.8 seconds. This unique hydraulic relief system provides

definite closure of the associated gas valve guaranteeing fail safe operation.

A visible disk fitted to the pump shaft indicates the entire stroke range of the actuator.

The disk also operates optional potential free switches via a set of levers. The

switching position of the auxiliary switch is adjustable over the entire stroke. The proof

of closure switch is non-adjustable.

Regulating Function During the burner pre-purge period, when the gas valve is closed, only the air pressure

acts on the regulator causing the air diaphragm to move to the left and close the

regulating hydraulic bypass valve. When the actuator is powered the gas valve begins to

open. The downstream differential gas pressure immediately begins to increase until the

downstream gas pressure is in balance with the air pressure (in accordance with the

pressure ratio adjusted on the regulator). The bypass valve is now partially open so that

the oil flow supplied by the pump is identical to the return flow. Unlike conventional

direct acting regulators the SKP70… servo operated regulating system displays virtually

zero droop (offset) across the turndown range.

If, for example, heat demand increases, the air damper would open further increasing

the air pressure. The air diaphragm would move to the left, causing the bypass valve to

close and the gas valve to open further. The opening of the gas valve increases the

downstream gas pressure moving the gas diaphragm to the right until balance is

restored and the flow supplied by the pump is once again identical to the return flow

through the regulator bypass.

The gas to air pressure ratio is adjustable from 0.4:1 to 9:1. The setting is visible through

a window in the regulator. Once set, the gas to air pressure ratio remains constant over

the entire output range. The gas to air flow ratio will remain constant (provided that the

cross sections of the air and gas orifices in the burner head are fixed). The SKP70… is

not recommended for use with burners incorporating a sliding/continuously adjustable

head arrangement.

Many burner designs, because of reduced mixing energy at the low fire level, require

somewhat more low fire air in order to maintain optimum combustion parameters. To

accommodate this requirement the SKP70… incorporates a bias spring parallel

displacement adjustment which allows the characteristic of the regulator to be displaced

either towards excess air or reduced air.