1

PAD-4 Installation, Operation and Maintenance Manual

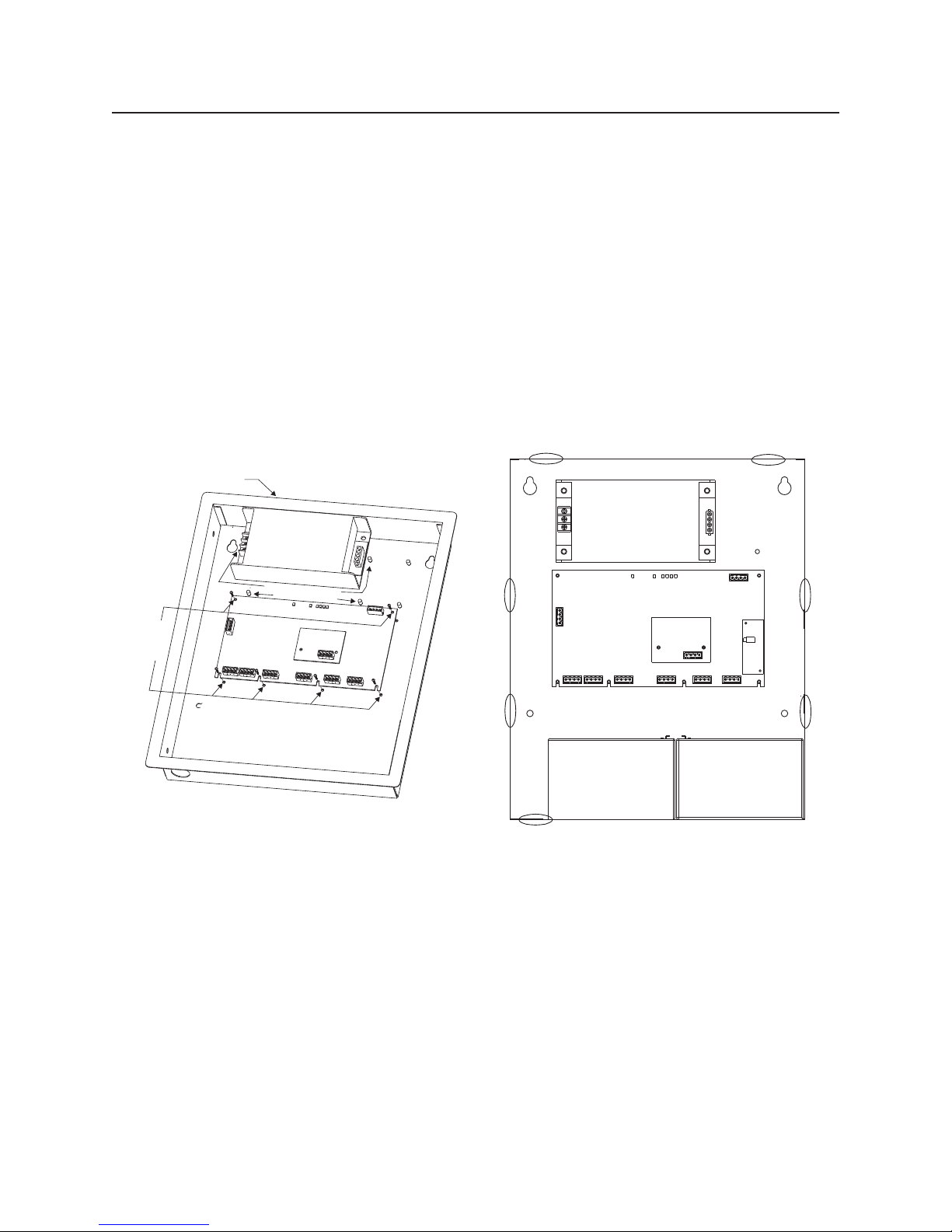

1. DESCRIPTIONS

The Model PAD-4 from Siemens Industry, Inc. is a

notification and auxiliary power expander that

provides up to 9 amps of 24 volt DC for powering

notification appliances and auxiliary devices. The

PAD-4 provides its own AC power connection,

battery charging circuit, and battery connections.

Used with a fire alarm control unit, this enables

you to connect and distribute power to many more

devices than your control unit may normally allow.

1.1 GENERAL DESIGN FEATURES

Inputs

The PAD-4 has two optically isolated inputs that

provide the connection from the fire alarm control

unit notification appliance circuit to the PAD-4. The

inputs also provide a connection for returning a

trouble condition to the control unit notification

appliance circuit.

The fire alarm control unit supervises its notification

appliance circuit used for communicating with the

PAD-4 the same way it supervises ordinary NACs.

The inputs on the PAD-4 monitor the polarity of the

voltage coming from the fire alarm control unit’s

NACs to determine when to operate the notifica-

tion appliance circuit outputs. The PAD-4 emulates

the trouble behavior of a NAC by opening the EOL

supervision current for trouble conditions. Note

that the PAD-4 will sense the polarity of the fire

alarm control unit’s NACs to drive the outputs

whether or not the supervision connection is intact.

The following situations will open the EOL supervi-

sion at the inputs indicating a trouble condition:

• No or low AC power. For AC Fail reporting, refer to

Section 5.1.4 for configuration and response times.

• No and low battery condition.

• Ground fault to the output wiring.

• Auxiliary power supply output over-current

condition.

• NAC output open, shorted or over-current

condition on outputs associated with its input.

• Failure of the battery charger.

Notes:

If input 1 controls all four outputs, a fault on any output

will cause input 1 to indicate trouble. The fault does not

affect input 2.

If input 1 controls outputs 1 and 2, and input 2 controls

outputs 3 and 4, a fault condition on output 3 or 4 will

cause input 2 to indicate trouble. The fault does not

affect input 1.

Once the PAD-4’s inputs and outputs are activated, the

fire alarm control unit will not be able to sense trouble

conditions through its notification appliance circuit

connected to the PAD-4 input circuits. Use the PAD-4

trouble relay when it is necessary to monitor trouble

conditions and active alarm conditions at the same time.

Notification Appliance Circuit Outputs

The PAD-4 has four dedicated, power-limited, NAC

outputs that can be configured as two Class A

(Style Z) or four Class B (Style Y) circuits. An

additional two Class A (Style Z) circuits are

available when the PAD-4-CLSA module is in-

stalled.

The PAD-4 provides four configuration options

that will set the outputs as slaves that will follow

the input. If the inputs are on constant, they may

be configured as ANSI temporal code, Sync

strobe/horn operation or carbon monoxide (CO)

alarms.

Each of the four outputs is rated at 3 amps,

though a total of 6 amps maximum (or 9 amps

depending on power supply) can be drawn from

the PAD-4 outputs. The yellow Output LEDs

(DS1-DS4) flash to indicate an open, shorted or

over-current condition on its associated NAC

Output. The yellow Output LEDs are on steady to

indicate activation of the associated NAC output.

Selection of which input controls which output,

and which inputs are Class A (Style Z) and Class

B (Style Y) is done using the 10 position DIP

switch on the printed circuit board. Refer to

Section 5 for DIP switch settings.

The PAD-4-CLSA module, optional for UL installa-

tions but required for ULC installations, provides an

additional two Class A (Style Z) notification appli-

ance circuits to the PAD-4. When configured for

ULC operation, it also provides a Form A contact for

ground fault detection signaling. One PAD-4-CLSA

module can be mounted on the PAD-4. Refer to

P/N 315-050254 for more information.

Auxiliary Power Output

The PAD-4 has a dedicated, power limited,

auxiliary output that can be configured in two