i

Table of Contents

PREFACE ................................................................................................................................ ii

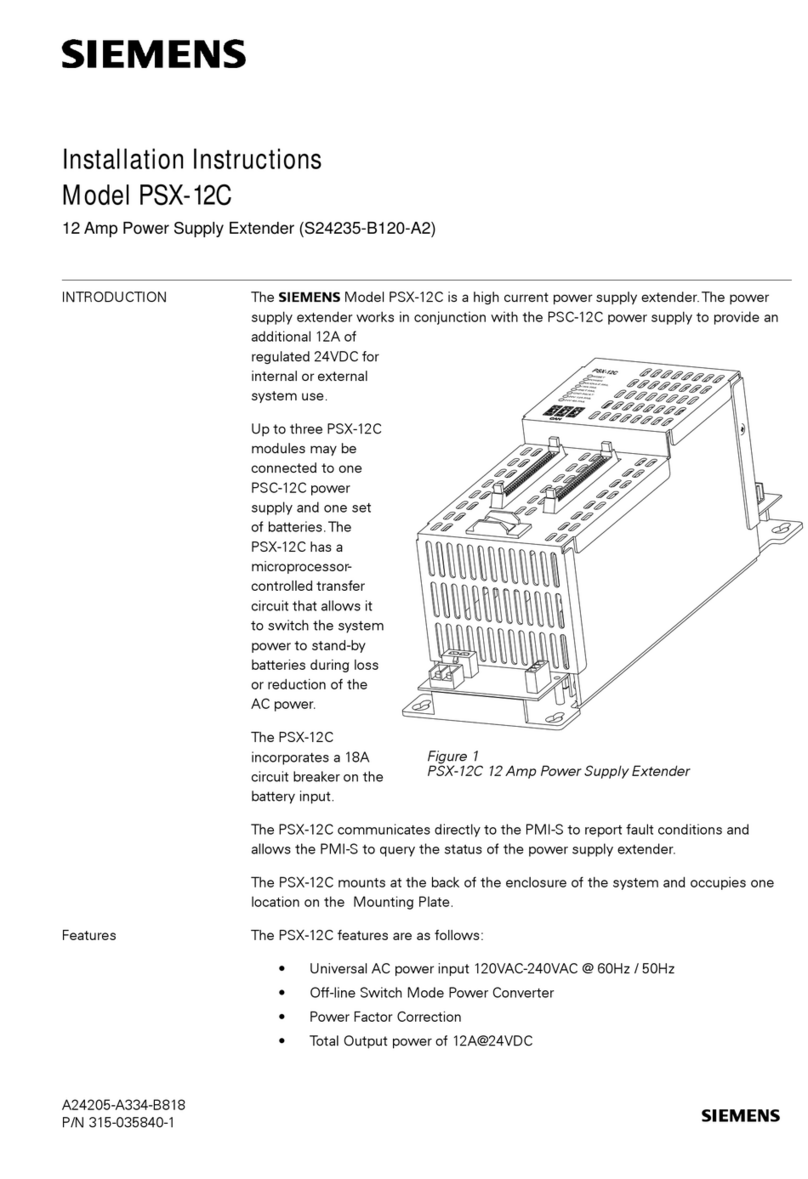

1. DESCRIPTIONS ...................................................................................................................... 1

1.1 General Design Features .................................................................................................. 1

1.2 Regulatory Standards........................................................................................................2

1.3 General Specifications....................................................................................................... 3

2. INSTALLATION ....................................................................................................................... 5

2.1 Mounting the Enclosure..................................................................................................... 5

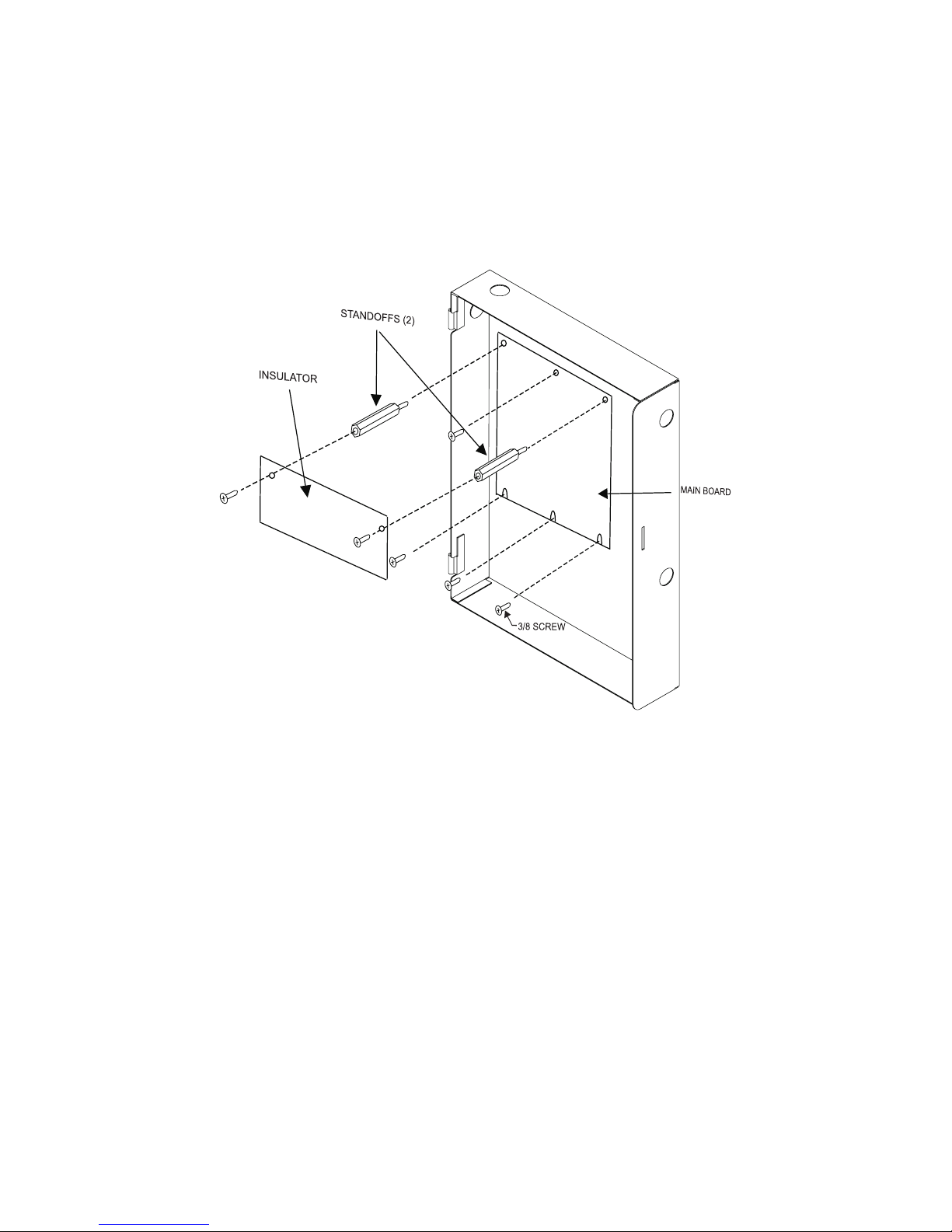

2.2 Control Unit Mounting........................................................................................................ 6

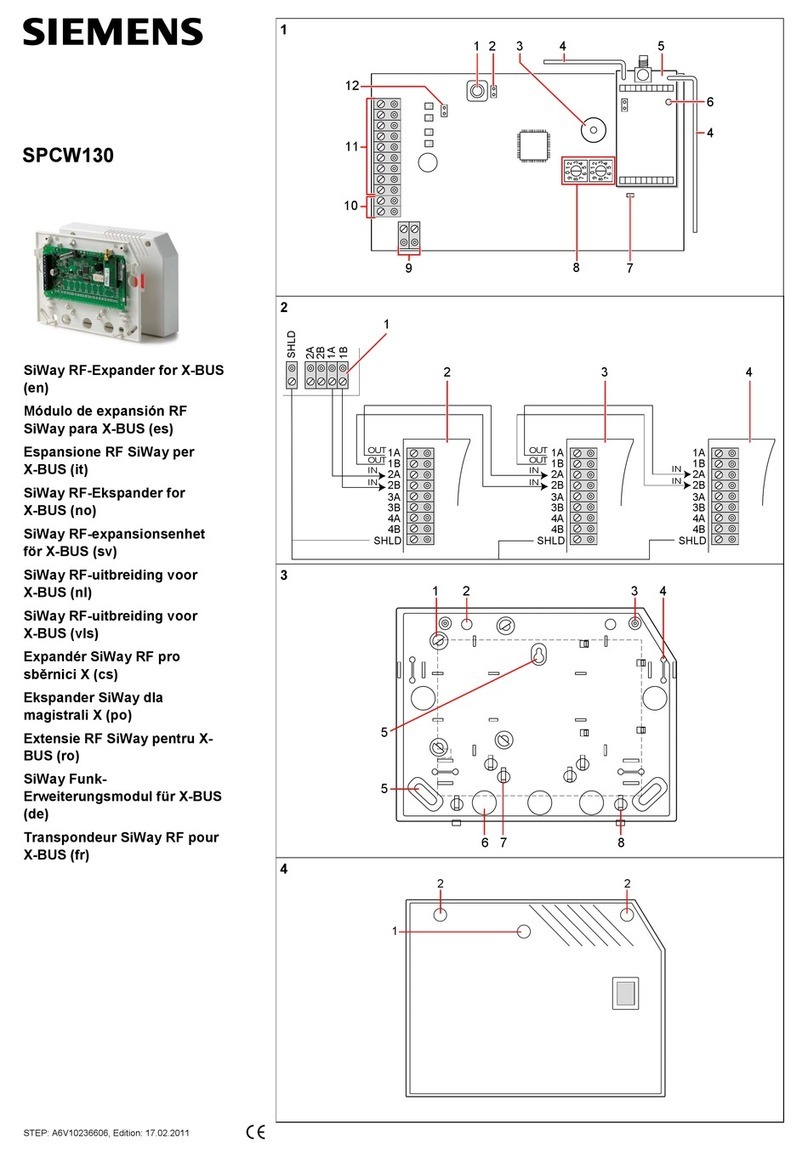

2.3 Wire Routing...................................................................................................................... 7

2.4 Terminal Descriptions and Electrical Ratings.................................................................... 8

2.5 Wiring The PAD-3.............................................................................................................. 9

2.5.1 AC Wiring......................................................................................................................... 10

2.5.2 Battery Connection .......................................................................................................... 11

2.5.2.1 Multiple Module Battery Connection................................................................................ 12

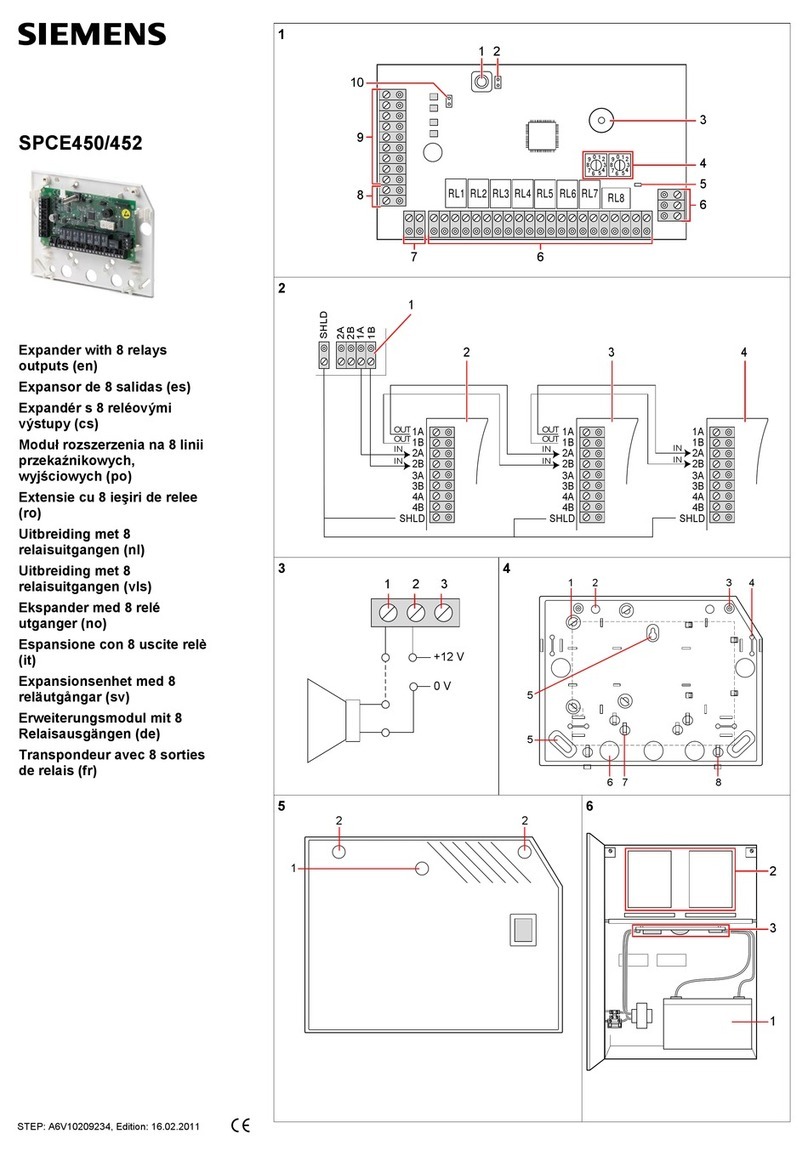

2.5.3 Style Y (Class B) Input/Output NAC Wiring..................................................................... 13

2.5.4 Style Z (Class A) Input/Output NAC Wiring..................................................................... 14

2.5.5 Auxiliary Power Supply Output ........................................................................................ 15

2.5.6 Common Trouble Relay................................................................................................... 15

2.5.7 AC Fail Relay................................................................................................................... 16

2.6 Ground Fault Detection Enable/Disable.......................................................................... 16

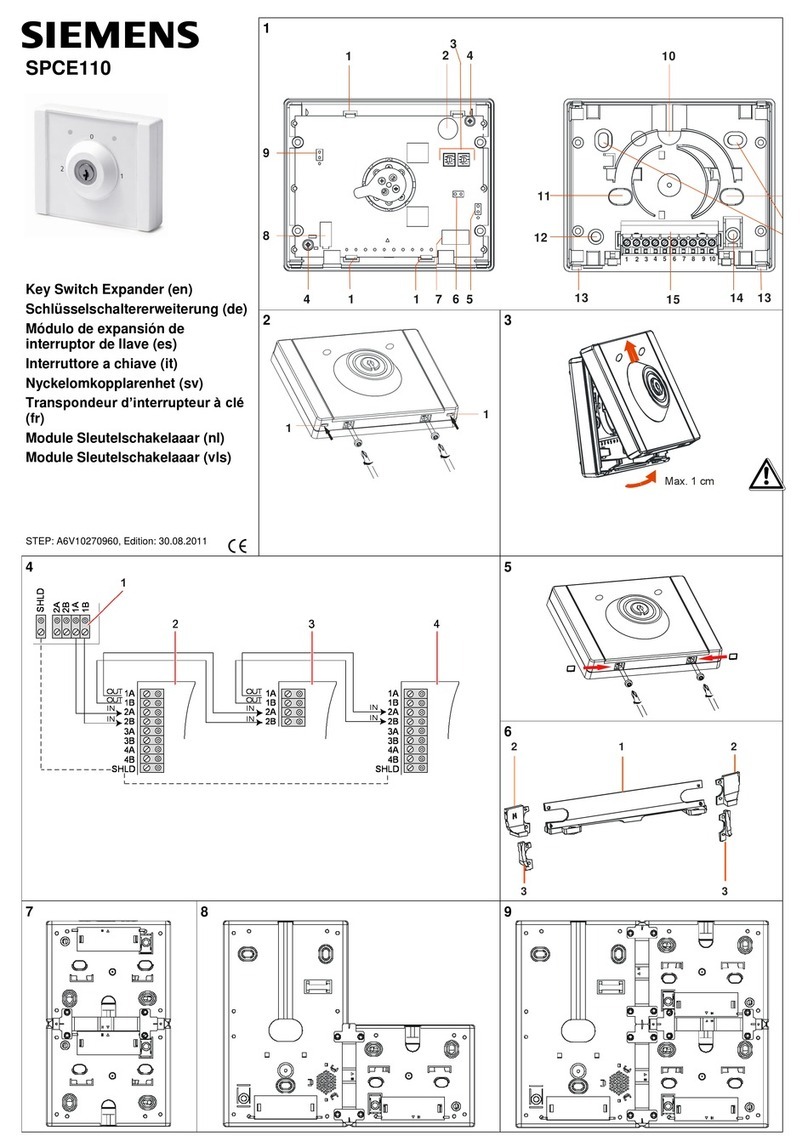

3. CONNECTION TO CONTROL UNITS .................................................................................. 17

4. SAMPLE APPLICATIONS .....................................................................................................27

4.1 Notification Appliance Power Applications ...................................................................... 27

4.2 Door Holder Applications................................................................................................. 32

5. PROGRAMMING ................................................................................................................... 33

5.1 Dip Switch Settings.......................................................................................................... 33

5.1.1 Selecting the Input/Output Configuration ........................................................................ 34

5.1.2 Setting the Auxiliary Output ............................................................................................. 35

5.1.3 Setting the Input’s Control of their NACs......................................................................... 36

5.1.4 Setting the AC Power Fault Reporting Delay .................................................................. 37

5.2 Jumper Settings............................................................................................................... 38

6. REFERENCE DATA .............................................................................................................. 39

6.1 Wire Selection Guides ..................................................................................................... 39

6.1.1 Resistance of Solid Copper Wire..................................................................................... 39

6.2 Battery Size Calculations................................................................................................. 40

7. COMPATIBLE DEVICES ....................................................................................................... 41

8. TROUBLESHOOTING........................................................................................................... 41

8.1 LED Indicators ................................................................................................................. 41

8.2 Improper Operation .........................................................................................................41

8.3 Trouble Conditions ..........................................................................................................42

8.4 Fuse Replacement .......................................................................................................... 43

9. BATTERY MAINTENANCE ................................................................................................... 44

10. GLOSSARY ........................................................................................................................... 45