P.T.O.

Technical Manual

Bus Coupling Unit (BTM)

117C12

–2CB12

/ Page 1

Product and Applications Description

Bus Coupling Units (BTM) provide the connection to the bus

for DELTA switches and wall box mounted control devices

with Bus Transceiver Interface (BTI).

The Bus Coupling Unit (BTM) comes with a mounting frame

for NEMA type wall boxes.

Application Program

The Bus Coupling Unit (BTM) does not require an application

program.

More information www.siemens.com/gamma-td

Example of Operation

Power supply

Input voltage

•Bus: DC 24 V (DC 21 ... 30 V)

Output voltage and current via BTI

•DC 5 V, 10 mA

•DC 20 V, 25 mA

Operator elements

The device has no operator elements.

Display elements

The device has no display elements.

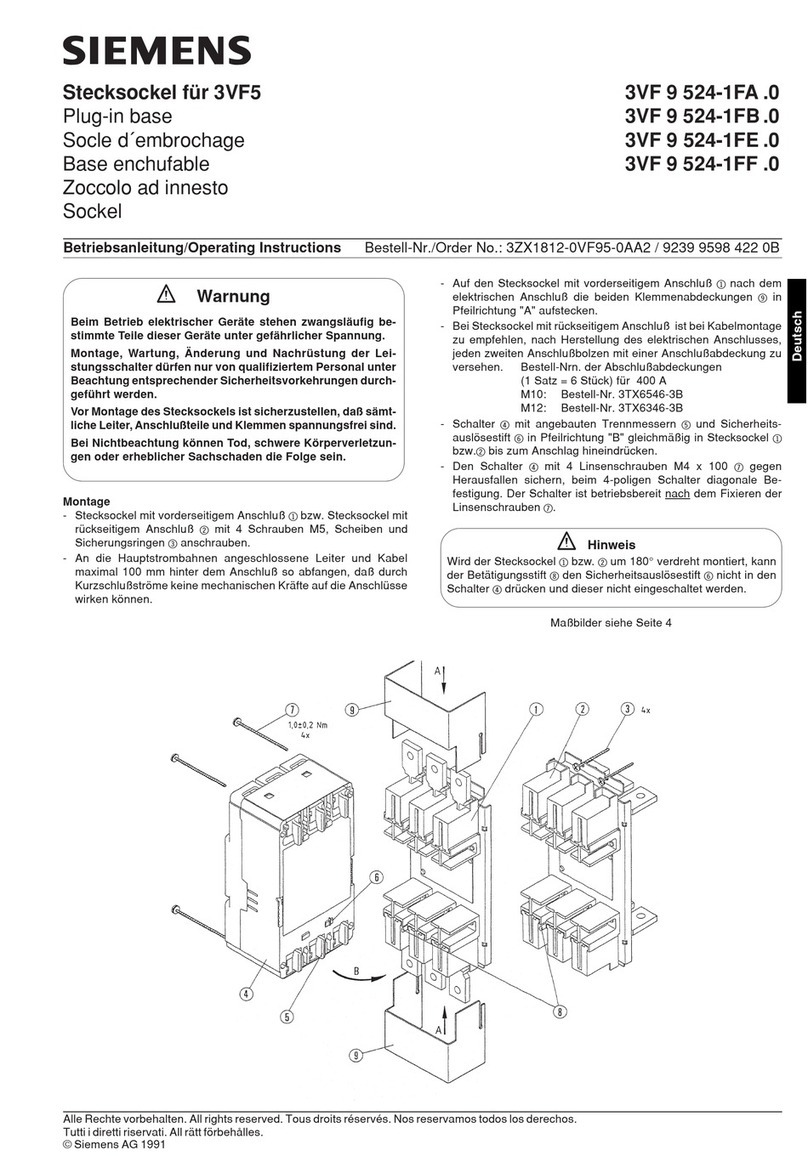

Connections

•Bus line : screwless bus connection block (red-black)

0.6…0.8 mm Ø single core

•10-pin socket (BTI): for connection of DELTA switches

and wall box mounted control devices with BTI plug

Physical specifications

•housing: plastic

•dimensions (L x W x D): 110 x 64 x 18 mm

•weight: approx. 60 g

•installation: mounted with mounting frame on NEMA

type wall boxes

Electrical safety

•degree of pollution (according to IEC 60664-1): 2

•protection (according to EN 60529): IP 20

•overvoltage class (according to IEC 60664-1): III

•bus: safety extra low voltage SELV DC 24 V

•the device complies with EN 50428

Electromagnetic compatibility

complies with EN 50428, EN 61000-6-2 and EN 62479

Environmental specifications

•climatic conditions: EN 50090-2-2

•ambient temperature operating: - 5 ... + 45 °C

•ambient temperature non-op.: - 25 ... + 70 °C

•relative humidity (non-condensing): 5 % to 93 %

Markings

EIB, KNX

Listings and Certifications

CE mark

complies with the EMC regulations (residential and func-

tional buildings) and low voltage regulations

Electromagnetic compatibility

USA:

This device complies with part 15 of the FCC Rules. Opera-

tion is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, in-

cluding interference that may cause undesired operation.

This equipment has been tested and found to comply with

the limits for a Class B digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reason-

able protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in ac-

cordance with the instructions, may cause harmful interfer-

ence to radio communications. However, there is no guar-

antee that interference will not occur in a particular installa-

tion. If this equipment does cause harmful interference to

radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to

try to correct the interference by one or more of the follow-

ing measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and

receiver.

- Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician

for help.

This device complies with Part 15 of the FCC rules.

Changes or modifications not expressly approved by Sie-

mens Schweiz AG could void the user’s authority to operate

the equipment.

United States representative:

https://new.siemens.com/us/en/products/buildingtechnologies/home.html

Canada:

CAN ICES-3(B)/NMB-3(B)

USA