3

.0 INSTALLATION AND WIRING

The relia ility of any system depends to a great extent on the proper

installation of the control units, detectors, associated equipment, and

wiring. These instructions outline the requirements for a satisfactory

installation. Careful completion of each detail will provide an auto-

matic fire and smoke detection system that will e dependa le and

give relia le operation.

Connection instructions are mounted inside the chassis cover of the

CP-48. Additional wiring information is provided in this manual. Any

questions regarding the equipment or installation should e directed

to Siemens Building Technologies, Inc., or an authorized represen-

tative. Do not make any alteration without first consulting the a ove.

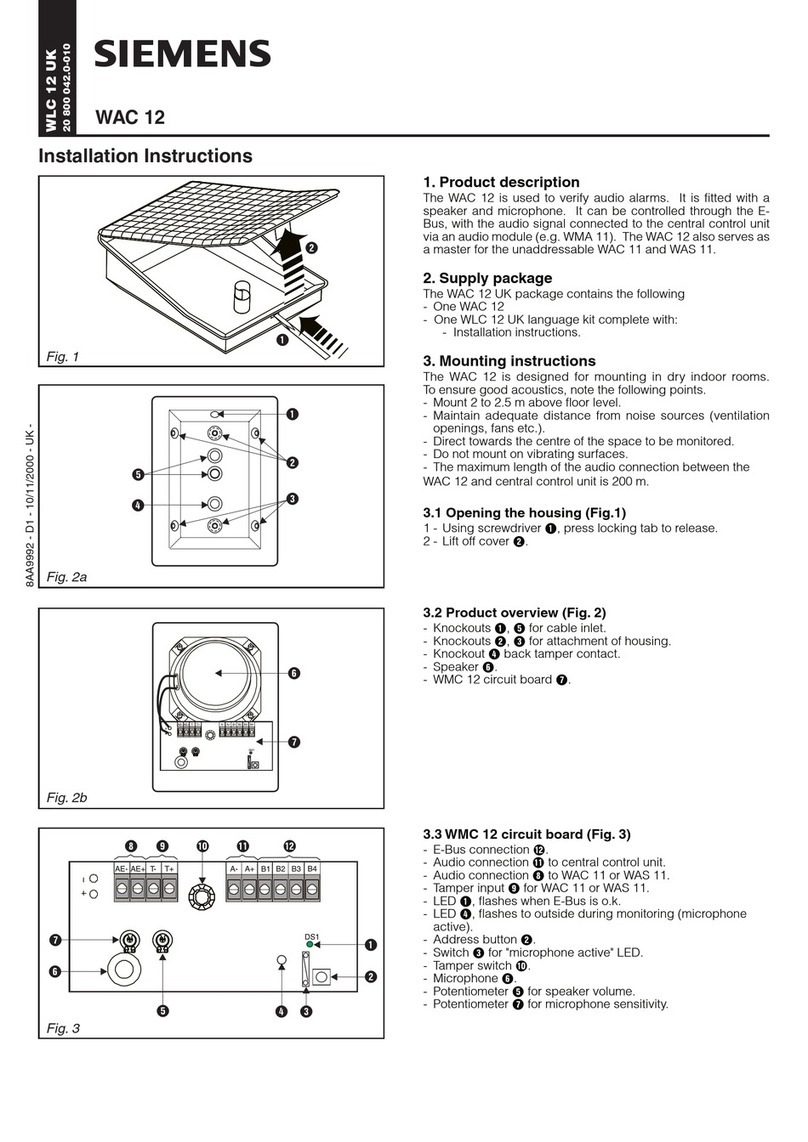

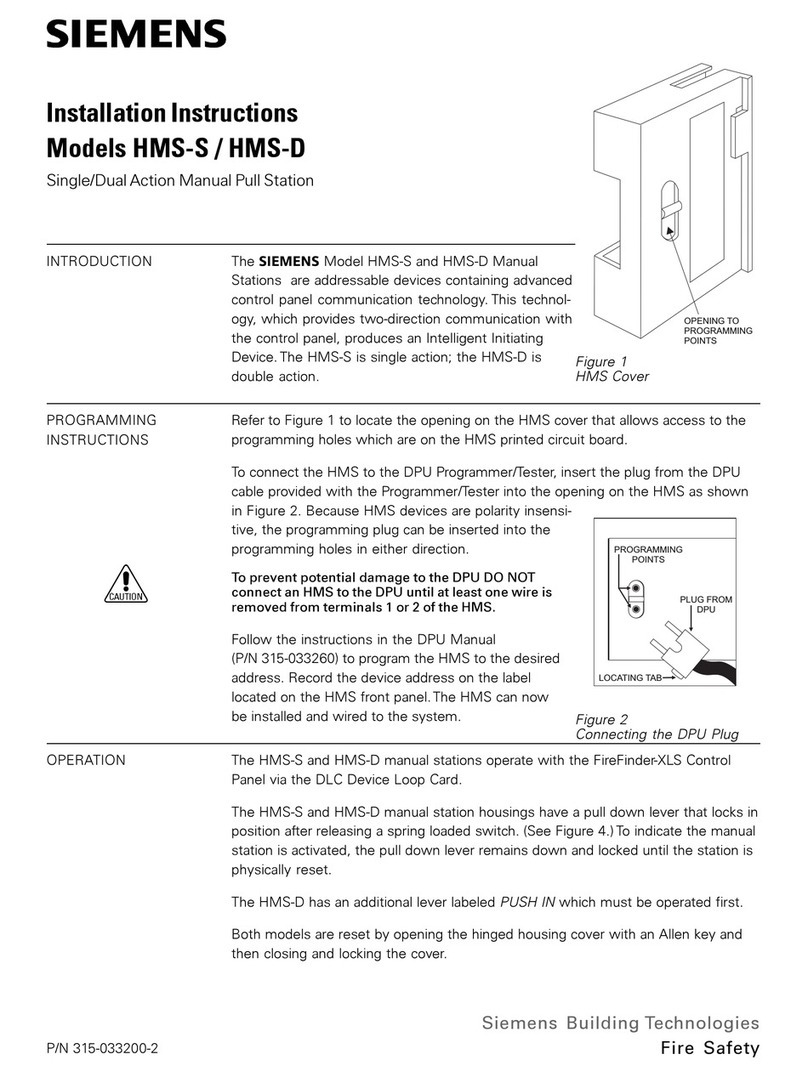

3.1 Mounting Control Units (Reter to Figure 2):

The Control Unit should e securely fastened to a shock and

vi ration free surface in a clean, dry area. It must e mounted

greater than 3 ft., ut less than 6 ft. from the floor. The location

should e easily visi le and readily accessi le for maintenance and

allow sufficient clearance to open the hinged front door.

Local regulations or codes generally require all wiring to, from, and

etween units to e carried in 1/2"-3/4" knockouts provided in the

top and ottom of the control unit. #18 AWG 300V insulation,

color coded wire is recommended for the detector circuits. A larger

size may e used if desired. For the DC power input use #14 AWG

300V wire.

3.2 Power Requirements:

The Model CP-48 Control Unit is designed to e operated from a

48 VDC power source having the positive line grounded, such as

is availa le in telephone community dial offices. The 48 VDC input

powers all internal circuitry. The DC voltage may vary etween the

limits of 42 and 55 volts and the limits should not e exceeded. The

CP-48 Control Unit, ungrounded leg, must e connected through a

separate circuit reaker or fuse directly to the DC power supply. No

other equipment may e supplied from this separate circuit reaker

or fuse. Wire must e run continuously from power source to

terminals in Control Unit. Refer to Wiring Diagram (Figure 3) for

terminal connections.

3.3 Installation of Conduit and Outlet Boxes:

Install outlet oxes and run conduit etween oxes and control unit.

Use 4"x21/8" deep octagon oxes for ionization, photoelectric, flame,

and plug-in thermal detectors. Do not mount oxes in direct air flow

from air-conditioning or ventilating system supply registers.

The control unit, and all detectors and alarm circuit conduit, must e

properly grounded. Insure that all conduit has clean threads and

makes good electrical contact etween control unit and outlet oxes.

3.4 Installation of Detector Bases:

a. Wiring (Refer to Figure 3):

Run wire in accordance with wiring diagram. Use at least #18 AWG

300 volt insulation, color coded wire for the detector circuits. Wiring

etween control unit and first detector ase, and all su sequent

detector ases must e continuous; no splices, wire nuts, solder or

any other type connection is permissi le. On rare occasions an

exception may e necessary due to an extremely long run. In this

case, the splice must e soldered.

Figure 2

Mounting Data

Technical Manuals Online! - http://www.tech-man.com