5

Contents

1. SETTING UP THE MACHINE ............................................................................................................... 6

2. ELECTRICAL CONNECTION............................................................................................................... 6

3. OPERATION.......................................................................................................................................... 7

A.WORKING PRINCIPLES ..............................................................................................................................7

B.GAS FLUSHING (OPTION)........................................................................................................................... 8

C.ELECTRICAL BAG CUT (OPTION).................................................................................................................8

D.PRESSURE REGULATOR (OPTION).............................................................................................................. 8

4. CONTROL ............................................................................................................................................. 9

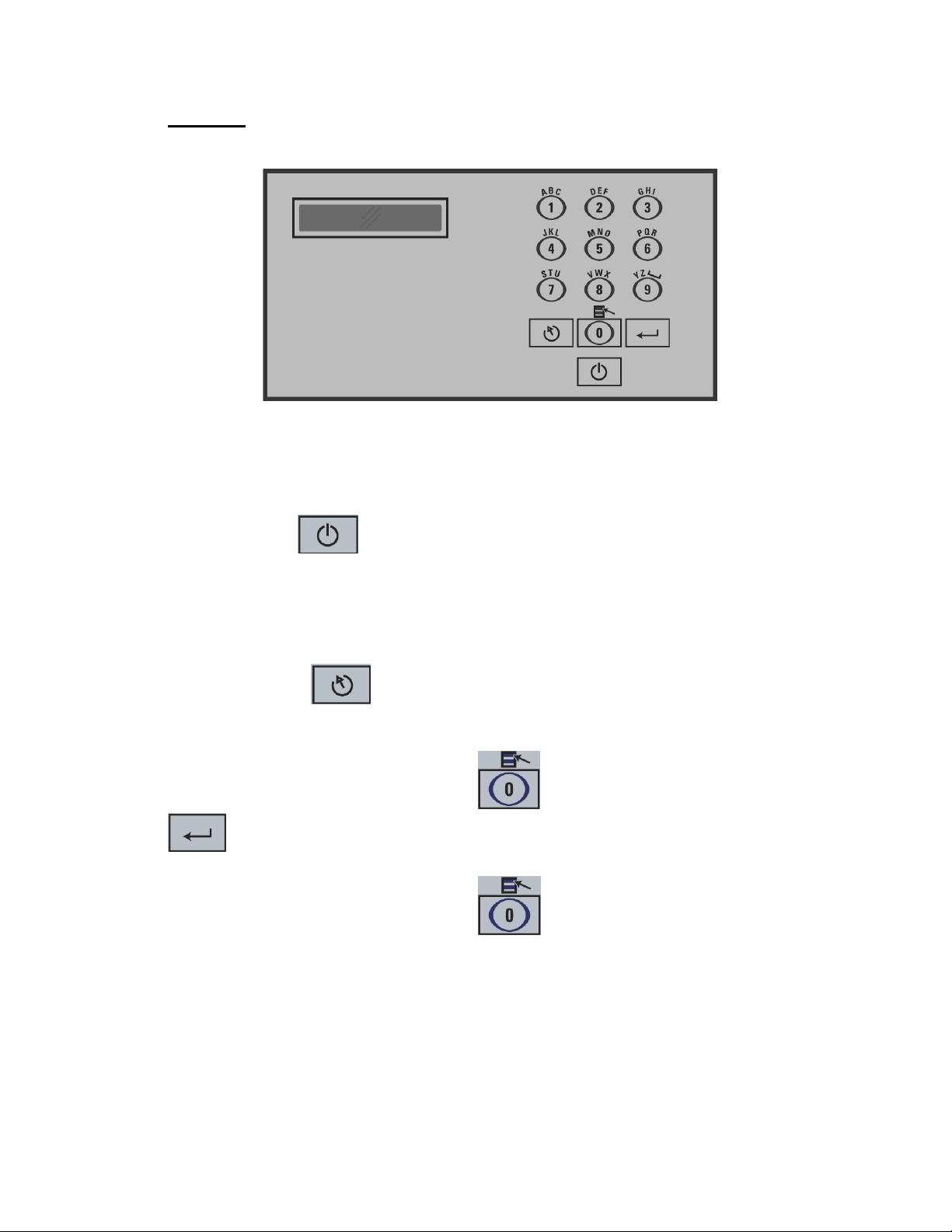

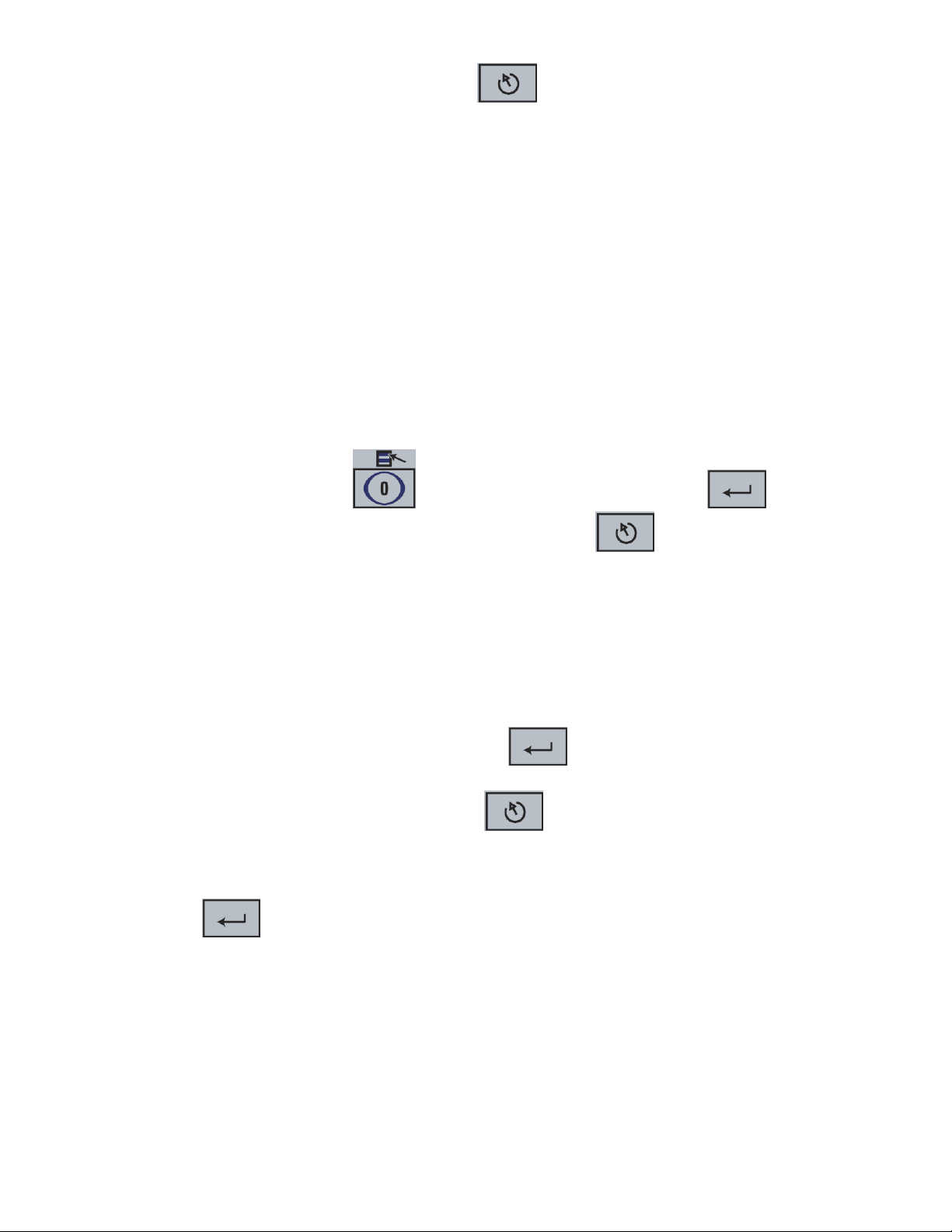

A.BASIC...................................................................................................................................................... 9

B.VACUUM LEVEL SETTING.........................................................................................................................10

C.VACUUM PLUS SETTING .......................................................................................................................... 11

D.GAS FLUSH LEVEL SETTING.....................................................................................................................11

E.SEALING TIME SETTING...........................................................................................................................12

F.PACKAGING CYCLE.................................................................................................................................12

G.SYSTEM MONITOR AND DIAGNOSTIC MENU...............................................................................................12

H.MENUS STRUCTURE ...............................................................................................................................13

5. DAILY CLEANING ..............................................................................................................................14

6. TROUBLESHOOTING ........................................................................................................................ 15

A.FAILURE DURING PACKAGING CYCLE........................................................................................................ 15

B.INSUFFICIENT VACUUM............................................................................................................................15

C.FAULTY SEAL .........................................................................................................................................15

D.FAULTY VALVE .......................................................................................................................................16

E.CONTROL BOARD FAILURE ......................................................................................................................16

7. MAINTENANCE ..................................................................................................................................16