Siqura TRAFFICPTZ ULTIMO User manual

TrafficPTZ Ultimo

Full HD PTZ IP camera system with advanced analytics

Installation Manual

Note: To ensure proper operation, please read this manual thoroughly before using the

product and retain the information for future reference.

Copyright © 2016 Siqura B.V.

All rights reserved.

TrafficPTZ Ultimo

Installation Manual v1 (162906-1)

MNVCUPT3_1511_EN + AIT55

Nothing from this publication may be copied, translated, reproduced, and/or published by

means of printing, photocopying, or by any other means without the prior written permission

of Siqura.

Siqura reserves the right to modify specifications stated in this manual.

Brand names

Any brand names mentioned in this manual are registered trademarks of their respective

owners.

Liability

Siqura accepts no liability for claims from third parties arising from improper use other than

that stated in this manual.

Although considerable care has been taken to ensure a correct and suitably comprehensive

description of all relevant product components, this manual may nonetheless contain errors

and inaccuracies. We invite you to offer your suggestions and comments by email via

[email protected]. Your feedback will help us to further improve our documentation.

How to contact us

If you have any comments or queries concerning any aspect related to the product, do not

hesitate to contact:

Siqura B.V.

Zuidelijk Halfrond 4

2801 DD Gouda

The Netherlands

General : +31 182 592 333

Fax : +31 182 592 123

E-mail : [email protected]

WWW : www.siqura.com

2

Contents

1 About this manual ..................................................................................... 5

1.1 Typographical conventions .................................................................... 5

1.2 Copyright and trademarks .................................................................... 5

2 Safety and compliance .............................................................................. 6

2.1 Safety rules ........................................................................................ 6

2.2 Compliance ......................................................................................... 7

3 Identification ............................................................................................ 8

3.1 Product description .............................................................................. 8

3.2 Product markings ................................................................................. 8

3.2.1 Checking the markings ..................................................................... 9

4 Versions .................................................................................................... 10

4.1 Integrated wiper .................................................................................. 10

5 Preparing the product for use ................................................................... 11

5.1 Safety precautions before use ............................................................... 11

5.2 Unpacking .......................................................................................... 11

5.3 Contents ............................................................................................ 11

5.4 Disposing of packaging material ............................................................ 12

5.5 Preparatory work before installation ....................................................... 12

5.5.1 Attaching the bracket ....................................................................... 12

5.5.2 Cables management ......................................................................... 12

6 Installation ............................................................................................... 13

6.1 Connecting the cables to the base .......................................................... 13

6.2 Fixing the base to the support ............................................................... 14

6.3 Connection of the power supply line ....................................................... 15

6.3.1 120 Vac and 230 Vac power line connection ........................................ 16

6.4 Connection of the Ethernet cable ........................................................... 17

6.5 Fixing the upper body .......................................................................... 18

7 Switching on ............................................................................................. 20

8 Network connection .................................................................................. 21

8.1 System requirements ........................................................................... 21

8.2 Connect to a LAN ................................................................................. 21

9 Get access to the unit ................................................................................ 22

9.1 Get access via web browser .................................................................. 22

9.2 Get access via Siqura Device Manager .................................................... 22

9.3 Get access via UPnP ............................................................................. 23

9.4 Log on to the unit ................................................................................ 23

10 Live Stream ............................................................................................... 24

11 Accessories ............................................................................................... 27

11.1 Washer .............................................................................................. 27

11.1.1 Washing system connection .............................................................. 27

11.2 Wall mount ......................................................................................... 28

3

11.3 Parapet bracket ................................................................................... 28

12 Maintaining ............................................................................................... 29

12.1 Fuses replacement ............................................................................... 29

13 Cleaning .................................................................................................... 31

13.1 Window and plastic cover cleaning ......................................................... 31

14 Disposal of waste materials ...................................................................... 32

15 Troubleshooting ........................................................................................ 33

16 Technical drawings ................................................................................... 34

Appendix: Replace the camera .................................................................. 35

Open the housing ................................................................................ 35

Disconnect cables ................................................................................ 36

Remove the module ............................................................................. 37

Install the new module ......................................................................... 38

Appendix: Housing board description ........................................................ 40

Board description ................................................................................. 40

Connection of the camera and motorised lens .......................................... 40

Appendix: Micro SD card ........................................................................... 42

Install a micro SD card ......................................................................... 42

Appendix: Reset button ............................................................................. 43

Location ............................................................................................. 43

Reset including network settings ............................................................ 43

Reset including network settings and firmware image ............................... 44

Index ...................................................................................................... 45

Contents

4

1 About this manual

Before installing and using this unit, read this manual carefully. Be sure to keep it handy for

later reference.

In This Chapter

1.1 Typographical conventions....................................................................................... 5

1.2 Copyright and trademarks........................................................................................5

1.1 Typographical conventions

DANGER!

High-level hazard.

Risk of electric shock. Disconnect the power supply before proceeding

with any operation, unless indicated otherwise.

DANGER!

Hot surface.

Avoid contact. Surfaces are hot and may cause personal injury if

touched.

DANGER!

Mechanical hazard.

Risk of crushing or shearing.

CAUTION!

Medium-level hazard.

This operation is very important for the system to function properly.

Please read the procedure described very carefully and carry it out as

instructed.

INFO

Description of system specifications.

We recommend reading this part carefully in order to understand the

subsequent stages.

1.2 Copyright and trademarks

The quoted names of products or companies are trademarks or registered trademarks.

5

2 Safety and compliance

In This Chapter

2.1 Safety rules........................................................................................................... 6

2.2 Compliance............................................................................................................7

2.1 Safety rules

CAUTION! The electrical system to which the unit is connected must be

equipped with a 20 A max automatic bipolar circuit breaker. This

circuit breaker must be of the Listed type. The minimum distance

between the contacts must be 3 mm (0.1 in). The circuit breaker must

be provided with protection against the fault current towards the

ground (differential) and the overcurrent (magnetothermal).

CAUTION! Hazardous moving parts. Keep fingers and other body parts

away.

CAUTION! The device must be installed only and exclusively by skilled

technical personnel.

CAUTION! For continued protection against risk of fire, replace only

with same type and rating of fuse. Fuses must be replaced only by

service personnel.

CAUTION! TNV-1 installation type. The installation is type TNV-1, do

not connect it to SELV circuits.

CAUTION! In order to reduce the risk of fire, only use UL Listed or CSA

certified cables sizes greater than or equal to 0.13 mm² (26 AWG).

● The manufacturer declines all responsibility for any damage caused by an improper use of

the appliances mentioned in this manual. Furthermore, the manufacturer reserves the

right to modify its contents without any prior notice. The documentation contained in this

manual has been collected with great care. The manufacturer, however, cannot take any

liability for its use. The same thing can be said for any person or company involved in the

creation and production of this manual.

● Before proceeding with the installation, check the supplied material to make sure it

corresponds to the order specification by examining the identification labels (see "Product

markings" on page 8).

● Never, under any circumstances, make any changes or connections that are not shown in

this handbook. Improper use of the appliance can cause serious hazards, risking the safety

of personnel and of the installation.

● The device should be mounted so that it is accessible only to the technician/installer

because the moving parts constitute a residual risk of injury caused by movement of said

parts.

● Do not allow children or unauthorised people to use the appliance.

● Only skilled personnel should carry out maintenance on the device. When carrying out

maintenance, the operator is exposed to the risk of electrocution and other hazards.

● Handle the unit with great care. High mechanical stress could damage it.

6

● Do not use the appliance in the presence of inflammable substances.

● If it is necessary to transport the device, this should be done with great care. Abrupt

stops, bumps and violent impact could damage the unit or injure the user.

● Use only the accessories indicated by the manufacturer. Any change that is not expressly

approved by the manufacturer will invalidate the guarantee.

● Use only original spare parts. Non-original spare parts could cause fire, electrical discharge

or other hazards.

● Do not use cables that seem worn or old.

● Before connecting all the cables make sure the device is properly connected to the earth

circuit.

● Before starting any operation, make sure the power supply is disconnected.

● The appliance should only be considered switched off when the power supply has been

disconnected and the connecting cables to other devices have been removed.

● Connect the device to a power source corresponding to the indications given on the

marking label. Before proceeding with the installation make sure that the power line is

properly isolated. The supply voltage should never exceed the limit (±10%).

● Make especially sure that the power supply line is insulated at a sufficient distance from all

the other cables, including lightning protection devices.

● Installation category (also called Overvoltage Category) specifies the level of mains

voltage surges that the equipment will be subjected to. The category depends upon the

location of the equipment, and on any external surge protection provided. Equipment in an

industrial environment, directly connected to major feeders/short branch circuits, is

subjected to Installation Category III. If this is the case, a reduction to Installation

Category II is required. This can be achieved by use of an insulating transformer with an

earthed screen between primary and secondary, or by fitting listed Surge Protective

Devices (SPDs) from live to neutral and from neutral to earth. Listed SPDs shall be

designed for repeated limiting of transient voltage surges, suitable rated for operating

voltage and designated as follows: Type 2 (Permanently connected SPDs intended for

installation on the load side of the service equipment overcurrent device); Nominal

Discharge Current (In) 20 kA min. For example: FERRAZ SHAWMUT, STT2240SPG-CN,

STT2BL240SPG-CN rated 120 Vac / 240 Vac, (In=20 kA). Maximum distance between

installation and reduction is 5 m.

● A disconnecting device, readily and easily accessible, must be incorporated in the electrical

system of the building for rapid intervention.

● The unit has been made for connection using a 3-pole cable. To make a correct connection

to the earth circuit, follow the instructions in this handbook.

● The separate protective earthing terminal provided on this product shall be permanently

connected to earth.

● If the device has to be removed from the installation, always disconnect the earth cable

last.

● Take all necessary precautions to prevent the apparatus from being damaged by

electrostatic discharge.

2.2 Compliance

The EU Declaration of Conformity for this product is available for download at

www.siqura.com/support-files.

Safety and compliance

7

3 Identification

In This Chapter

3.1 Product description................................................................................................. 8

3.2 Product markings....................................................................................................8

3.1 Product description

The Siqura® TrafficPTZ Ultimo is a high-precision, full-featured network PTZ camera providing

high-quality, high-definition images. The tightly integrated 30x optical zoom, autofocus lens

makes for the easiest installation and remote adjustment.

The TrafficPTZ Ultimo ensures maximum surveillance coverage in all outdoor environments,

even the most difficult. It can operate 24 hours a day in demanding security applications,

without requiring maintenance work.

Open standards

Its careful assembly and compliance to open standards ensure that the TrafficPTZ Ultimo

integrates with the most common VMSes out of the box. If you wish to incorporate the

camera’s special features in your dedicated client software, the Siqura Programming Interface

offers an easy HTTP API for guaranteed interoperability. This makes the camera an

outstanding candidate for projects which require customisation. Moreover, being ONVIF Profile

S compliant, the camera is supported even if your software does not have a dedicated driver.

Construction

The accurate top-mount construction ensures vision beyond the horizon and the continuous

rotation on the horizontal axis, combining high speed to absolute tracking accuracy, both in

manual mode and in patrol mode.

3.2 Product markings

The housing of the unit has a label complying with CE markings.

The label shows:

● Housing model identification code (Extended 3/9 bar code)

● Power supply (Volt)

● Frequency (Hertz)

● Current consumption (Amps)

● Weatherproof standard (IP)

● Serial number

8

The Siqura product label is located inside the upper half of the body.

The label shows:

● Model number

● Article number

● Power supply

● RoHS compliancy

● MAC address

● IP address

● Serial number

3.2.1 Checking the markings

Before proceeding further with installation, make sure the material supplied corresponds to

the order specification by examining the marking labels.

Never, under any circumstances, make any changes or connections that are not shown in this

handbook. Improper use of the appliance can cause serious hazards, risking the safety of

personnel and of the installation.

Identification

9

4 Versions

In This Chapter

4.1 Integrated wiper................................................................................................... 10

4.1 Integrated wiper

The product is equipped with a wiper. It can be controlled from the web interface of the

TrafficPTZ Ultimo.

The product can also be equipped with an external pump that supplies water for the glass to

be cleaned. The pump can also be controlled from the web interface.

For further information, refer to section Washer (see "Washer" on

page 27).

10

5 Preparing the product for use

Any change that is not expressly approved by the manufacturer will

invalidate the guarantee.

The unit must not be dismantled or tampered with. The only exceptions

are those concerning the assembly and maintenance operations

stipulated in this manual.

In This Chapter

5.1 Safety precautions before use.................................................................................11

5.2 Unpacking............................................................................................................11

5.3 Contents..............................................................................................................11

5.4 Disposing of packaging material..............................................................................12

5.5 Preparatory work before installation........................................................................ 12

5.1 Safety precautions before use

The appliance includes moving parts. Make sure that the unit is

positioned where it is inaccessible under normal operating conditions.

5.2 Unpacking

When the product is delivered, make sure that the package is intact and that there are no

signs that it has been dropped or scratched.

If there are obvious signs of damage, contact the supplier immediately.

Keep the packaging in case you need to send the product for repairs.

5.3 Contents

Check the contents to make sure they correspond with the list of materials as below.

● Positioning unit

● Power supply base

● Sunshield

● Info sheet

● Accessories package:

- Allen wrenches

- Label

- Silicon sheath

- Reduction gaskets for cable glands

11

- Desiccant bag

- Bolts and screws

5.4 Disposing of packaging material

The packaging material can all be recycled. The installer technician will be responsible for

separating the material for disposal, and in any case for compliance with the legislation in

force where the device is to be used.

When returning a faulty product we recommend using the original packaging for shipping.

5.5 Preparatory work before installation

5.5.1 Attaching the bracket

Different types of supports are available (see "Accessories" on page 27). Choose a suitable

bracket for the installation.

Take special care when attaching and fastening down the apparatus.

The clamping system must be able to support at least 4 times the

weight of the entire equipment, including P&T, lenses and camera.

The device should be assembled vertically. Any other position could

impair the performance of the appliance.

Do not attach the device upside down.

5.5.2 Cables management

The connection cables should not be accessible from the outside. It is

necessary to fasten the cables securely to the support in order to

prevent excessive weight pulling them out accidentally.

You must use cables suited to the type of installation.

Insert the cables into the support so that they protrude by about 50 cm.

Preparing the product for use

12

6 Installation

Never, under any circumstances, make any changes or connections

that are not shown in this handbook. Failure to follow the connection

instructions that are given in the handbook may create serious safety

hazards for people and for the installation.

Do not change the wiring in the product as it is supplied to you. Failure

to follow this instruction may create serious safety hazards for people

and for the installation, and will also invalidate the guarantee.

If using the washer kit, the nozzle support should be installed before

positioning the pan & tilt and the wiring. For further explanations see

the specific handbook for the kit.

Inside the bottom cover there is a desiccant bag that is used to prevent

moisture formation in the base and near the connector boards. Remove

the bag before installation.

In This Chapter

6.1 Connecting the cables to the base........................................................................... 13

6.2 Fixing the base to the support................................................................................ 14

6.3 Connection of the power supply line........................................................................ 15

6.4 Connection of the Ethernet cable.............................................................................17

6.5 Fixing the upper body............................................................................................18

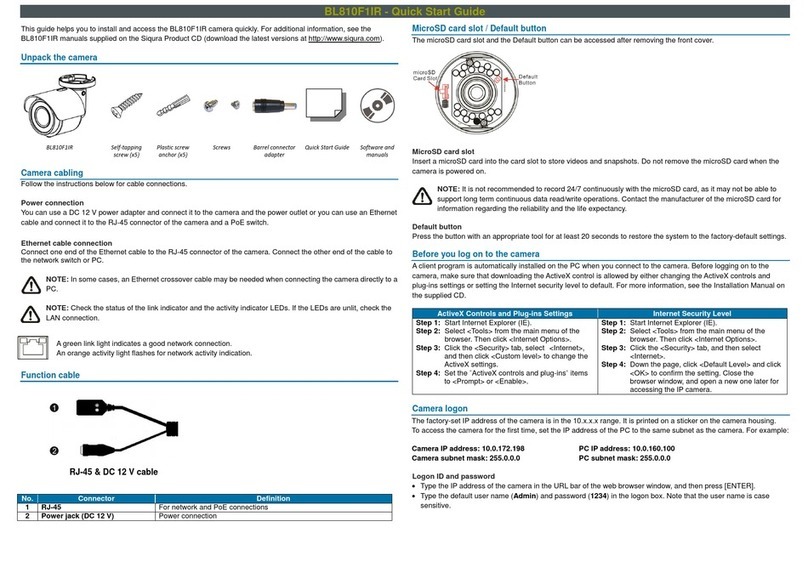

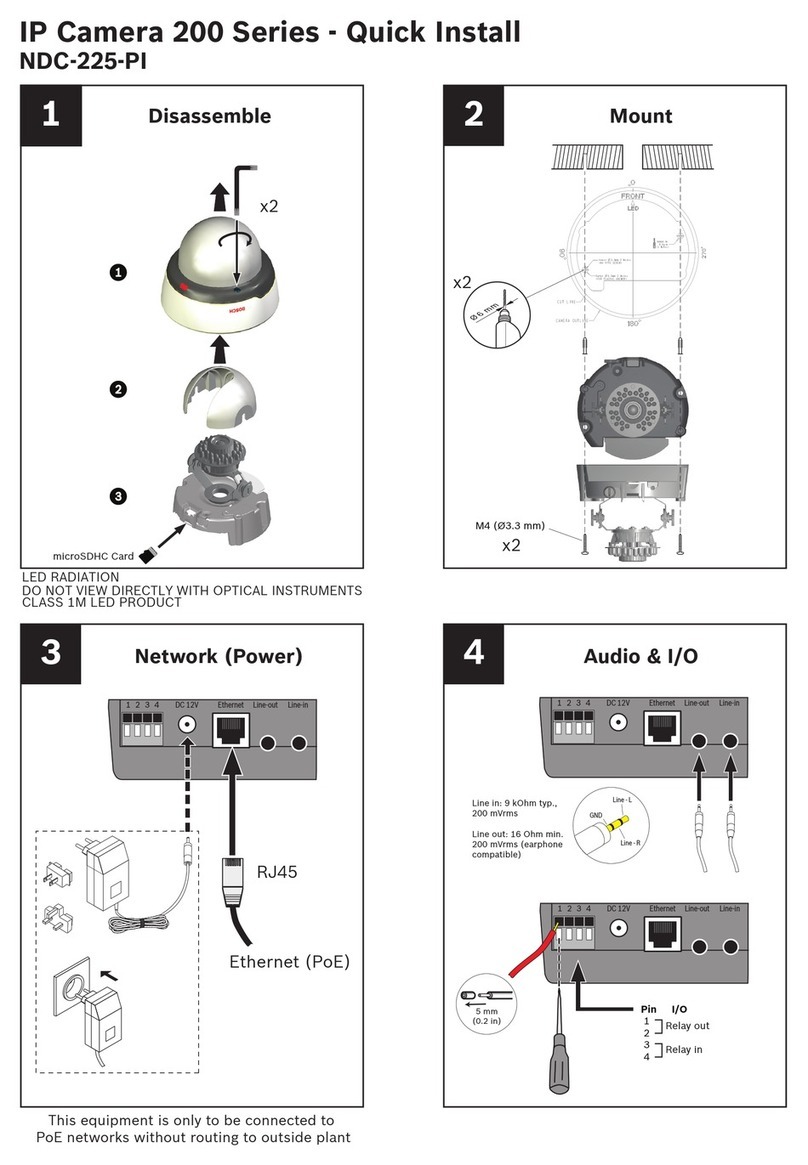

6.1 Connecting the cables to the base

Insert the cables into the cable glands holding the base at about 20 cm from the support.

Each cable (power and Ethernet) has its own cable gland. Tighten the cable glands. The cable

glands are suitable for cables with a diameter between 5 mm and 10 mm.

13

Note that an RJ-45 connector will not pass through the cable gland.

Pass the Ethernet cable through the gland and then crimp the

connector on the cable.

To ensure reliable operation, it is recommended that only Cat 5e STP

cable is used to connect the TrafficPTZ Ultimo to the network.

Pay attention to the fixing. Tightening torque: 5 Nm.

For cables diameter from 3 mm to 7 mm use the supplied gaskets.

6.2 Fixing the base to the support

Once you have positioned the gasket (01), fix the base (02) onto the bracket (03) with screws

(04), serrated washers (05) and screw rings (06).

Align the 3 notches on the base with those on the support as shown in the following figure.

Installation

14

Apply a thread-locker on the holes of the screws (Loctite 243®)

Pay attention to the fixing. Tightening torque: 4 Nm.

6.3 Connection of the power supply line

Depending on the version, the device can be provided with different power supply voltages.

Their value is shown on the product identification label (see "Product markings" on page 8)

and on a yellow sticker inside the base.

Electrical connections must be performed with the power supply

disconnected and the circuit-breaker open.

When commencing installation make sure that the specifications for

the power supply for the installation correspond with those required by

the device.

Make sure that the power source and connecting cables are suitable for

the power consumption of the system.

Installation

15

In case of using the TrafficPTZ Ultimo camera in an FCC Class B

emission critical environment, it is recommended to apply a cable snap

ferrite on the power cable for reduced emission. Recommended ferrite:

Würth 74271221. Place the ferrite as close to the housing as possible.

If no ferrite is used, the camera complies with FCC Class A.

Earth cable should be about 10 mm longer than the other two, so that

it will not be disconnected accidentally if pulled.

The power supply cable should also be covered by the silicone sheath

(01) supplied for this purpose. The silicone sheath must be fastened

with the corresponding tie (02).

6.3.1 120 Vac and 230 Vac power line connection

Cut the cables to the correct length and make the connections. Connect the power supply to

the terminal: CN1.

Connect the power supply cables as described in the table below.

Installation

16

CONNECTION OF THE POWER SUPPLY LINE

Colour Terminals

Power supply 230 Vac

Blue N (Neutral)

Brown L (Phase)

Yellow/Green

Power supply 120 Vac

Blue N (Neutral)

Brown L (Phase)

Yellow/Green

6.4 Connection of the Ethernet cable

Before crimping the Ethernet cable, arrange the wires in the correct order before you place

them in the RJ-45 connector. Working from left to right, the order of the wires is:

● Orange with a white stripe

● Orange

● Green with a white stripe

● Blue

● Blue with a white stripe

● Green

● Brown with a white stripe

● Brown

Connect the Ethernet cable to the connector, as shown below.

Installation

17

6.5 Fixing the upper body

Fix the upper body (01) to the base (02) using the fixing screws (03) equipped with gaskets

(04). Make sure the base seal is present and in good condition (05).

Pay attention to the fixing. Tightening torque: 4 Nm.

Installation

18

There is one anchoring position between the base and upper body.

Align side projections to obtain the correct positioning.

The dip switches of the unit are set for proper operation. It is not

necessary to modify the factory-default settings. Doing so may lead to

undesired results.

Installation

19

7 Switching on

Make sure that the unit and other components of the installation are

closed so that it is impossible to come into contact with live parts.

During normal operation the surface of the illuminator can reach high

temperatures. Do not allow direct contact and position the appliance

where it is inaccessible to unauthorised persons. Before touching

switch off the illuminator and allow to cool for a minimum period of 10

minutes.

Do not stay in the vicinity of the device when it is powered. Act on the

device only in the absence of a power supply.

Make sure that all parts are fastened down firmly and safely.

The automatic preheating (De-Ice) process could be started whenever

the device is switched on and the air temperature is below 0 °C. This

process is used to ensure that the device works properly even at low

temperatures. The duration ranges between 60 and 105 minutes,

depending on conditions.

The unit is switched on by connecting the power supply. After the power is supplied, the unit

performs self-test actions and then proceeds with pan and tilt movement. Depending on the

direction the camera is pointing this may take up to two minutes.

To switch off the unit, disconnect the power.

20

Table of contents

Other Siqura IP Camera manuals

Siqura

Siqura PD1022Z3-EI User manual

Siqura

Siqura FD1103M1-I User manual

Siqura

Siqura BC620 Series User manual

Siqura

Siqura HSD620PRH User manual

Siqura

Siqura IFD820 Series User manual

Siqura

Siqura FD810V1IR User manual

Siqura

Siqura HSD820 Series User manual

Siqura

Siqura BC820 User manual

Siqura

Siqura FD360IR Series User manual

Siqura

Siqura PD1103Z2-E User manual

Siqura

Siqura BC620WDR User manual

Siqura

Siqura BC1103 User manual

Siqura

Siqura FD360IR Series User manual

Siqura

Siqura BL810F1IR User manual

Siqura

Siqura FD820 Series User manual

Siqura

Siqura HSD622 User manual

Siqura

Siqura IFD822V2IR User manual

Siqura

Siqura HSD62x User manual

Siqura

Siqura BC820v2H3 User manual

Siqura

Siqura FD1004M1-EI User manual