SKC AirChek 52 User manual

Form 37714 Rev 1809

Page 1 of 13

www.skcinc.com

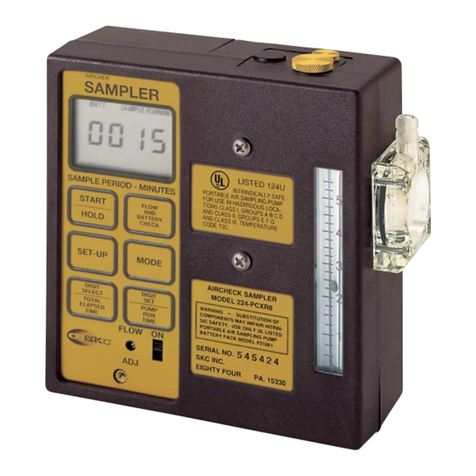

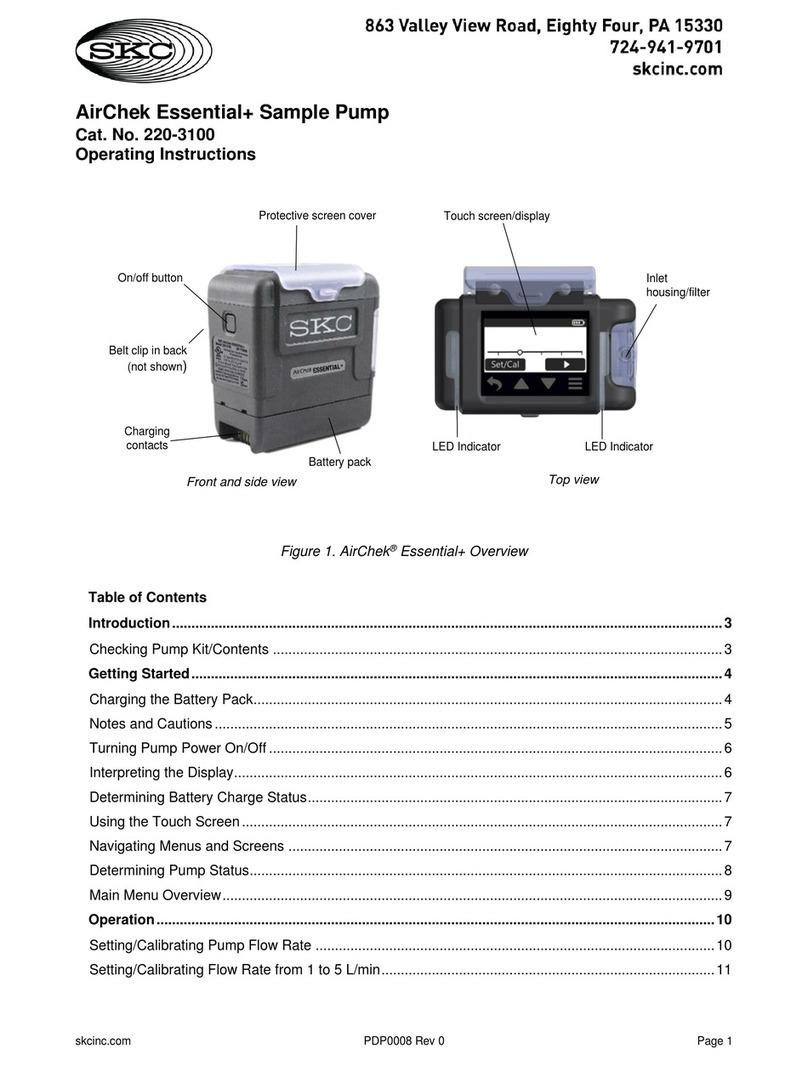

AirChek®52 Sample Pump

Cat. No. 224-52

Operating Instructions

863 Valley View Road, Eighty Four, PA 15330 USA • Tel: 724-941-9701 • www.skcinc.com

Top view

Protective control

cover (raised)

Pump inlet

(inlet filter underneath)

LCD

Flow

adjustment

screw

On/off button

Accessory

mounting screws

Battery pack

Front view Back view

Belt clip

Charging jack

Figure 1. AirChek 52 Sample Pump

Introduction

Description

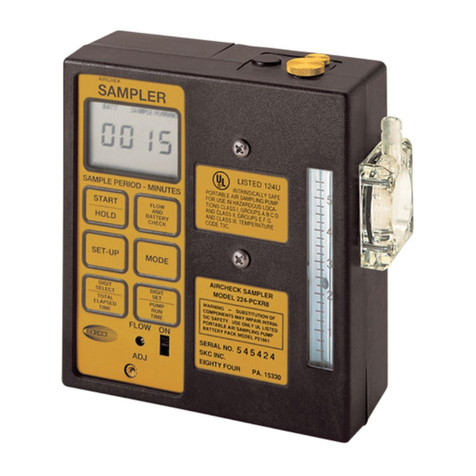

The AirChek 52 Sample Pump (Figure 1) is designed for rugged industrial use at flows from 5 to 3000 ml/min. Ideal for on-worker

applications, use the AirChek 52 for short-term or full-shift sampling with sorbent tubes, impingers, size-selective samplers, or filter cassees.

Checking Pump/Kit Contents

Use the table below to verify that you received all items associated with the Cat. No. ordered. If you are missing items, contact

SKC at 800-752-8472 (U.S. only) or 724-941-9701.

If You Ordered Cat. No. Your Package Should Contain

224-52 AirChek 52 Sample Pump with NiMH battery pack and screwdriver set

224-52-S AirChek 52 Sample Pump with NiMH battery pack and screwdriver set, single PowerFlex charger with cable,

Tygon tubing (3 feet, 1/4-inch ID), and collar clip with cable tie

224-52K AirChek 52 Sample Pump with NiMH battery pack and screwdriver set, single PowerFlex charger with cable,

filter cassette holder, Tygon tubing (3 feet, 1/4-inch ID), and soft-sided nylon carry case

Required Equipment

;1/4-inch ID tubing

;PowerFlex®Charger

;Low flow accessories if sampling at 5 to 500 ml/min. See Accessories.

Form 37714 Rev 1809

Page 2 of 13

www.skcinc.com

Charging train with

single PowerFlex charger

Charging

jack

Power

cable

Charger

Charging

cable

Getting Started

Charge the Battery Pack

For optimum charge, ensure that the pump is not running.

1. Activate the charger (follow PowerFlex Operating Instructions 40069).

2. Insert the charging cable connector into the charging port on the charger.

See right.

3. Insert the charging plug end of the cable into the jack on the back of the

pump’s baery pack (Figure 1).

4. Charge the baery completely (the LED at the port connected to the pump

is a steady green) before using the pump.

5. Disconnect the charging cable from the back of the pump’s baery pack.

Notes and Cautions

• To comply with intrinsic safety regulations, do not charge or operate the pump from the charger in hazardous locations.

• Using a non-approved charger voids any warranty.

• Using a repaired or rebuilt battery pack voids any warranty and the UL Listing for intrinsic safety.

• Using any device other than the approved battery pack to power the pump voids the UL Listing for intrinsic safety and any warranty.

• Ensure proper orientation of charging cable before plugging it into the charging jack. Improper orientation/contact will short-circuit

the battery and voids any warranty.

• Short-circuiting the battery pack will render it immediately inoperative.

• Failure to follow warnings and cautions voids any warranty.

• The battery pack may be kept on the SKC-approved charger for an indefinite time.

For more information on SKC pump battery packs, visit www.skcinc.com/catalog/pdf/instructions/1756.pdf.

Use the Pump with AC Power (Power option in non-hazardous locations)

Do not use the pump with the Battery Eliminator in hazardous locations. UL Listing for intrinsic safety is not in effect during pump

operation with the Battery Eliminator.

The Baery Eliminator is an accessory that converts alternating current (AC) to direct current (DC) from which the pump can be operated

for extended runs. The Baery Eliminator should be used in non-hazardous locations only. See Accessories.

1. Remove the baery pack from the pump. See Replace the Baery Pack.

2. The Baery Eliminator is comprised of two pieces, a wall cube and a power adapter. Plug the wall cube into a standard wall outlet

and insert its plug end into the power adapter.

3. Fit the power adapter on the pump in place of the baery pack.

Form 37714 Rev 1809

Page 3 of 13

www.skcinc.com

Operation

High Flow Applications (1000 to 3000 ml/min)

Set/Calibrate Flow Rate

• Allow pump to equilibrate after moving it from one temperature extreme to another.

• Charge battery completely before calibration and sampling.

1. Ensure that the baery is fully charged and that the pump has run for five minutes before

calibrating. Leave the pump running.

2. Prepare the calibrator. See calibrator instructions.

3. Set up a calibration train: Using flexible tubing, connect the calibrator outlet (suction port)

to the representative sample medium inlet. Using ¼-inch Tygon tubing, connect the sample

medium outlet to the pump inlet. See right.

4. Using a screwdriver, set the pump flow rate by turning the flow adjustment screw on top of the pump (Figure 1), clockwise to increase

or counterclockwise to decrease flow, until the calibrator indicates the method-specified flow rate. Take a minimum of three readings

and record the average flow rate, as per OSHA/NIOSH instructions.

5. Press the on/offbuon to turn offthe pump. Disconnect the calibrator and flexible tubing from the representative sample medium

and proceed to Set Up/Sample.

Set Up/Sample

• Allow pump to equilibrate after moving it from one temperature extreme to another.

• Protect sample pump from weather when sampling outdoors.

• Powering the pump with any device other than the approved battery pack voids the UL Listing for intrinsic safety.

• Do not use the pump with the Battery Eliminator in hazardous locations. UL Listing for intrinsic safety is not in effect

during pump operation with Battery Eliminator.

• Use of any device other than the approved battery pack or Battery Eliminator to power the pump voids any warranty.

• Charge battery completely before calibration and sampling.

1. Replace the representative sample medium with new unexposed medium for sample collection.

2. Place the sample medium where appropriate for sampling.

a. For personal sampling, clip the sample collection medium to the worker in the breathing zone and the

pump to the worker’s belt using the belt clip.

When using an impinger, an in-line trap (SKC Cat. No. 225-22 or 225-22-01) is required between the pump and

impinger to prevent fumes from accidentally being drawn into the sampler. Failure to use an appropriate in-line

trap during impinger sampling voids any warranty.

b. For sampling with an impinger, mount the single or dual impinger and trap (SKC Cat. No. 225-20-01 or

225-20-02) to the face of the sampler using the accessory mounting screws (Figure 1) or place them in a

holster at the worker’s waist.

3. Press the on/offbuon to clear the elapsed time displayed on the LCD and to start sampling. Record the

start time and other pertinent information. The LCD will automatically display elapsed pump run time.

See below.

Possible Displays During Sampling

Flow or Baery Fault Shutdown - If the pump is unable to compensate due to excessive back pressure or a low baery

condition exists, it will shut down and timing functions will pause. The LCD will display either a baery-shaped icon

or a flow fault icon () depending on the cause of the shutdown. Upon flow fault, the pump will aempt to restart up

to five times. To restart from flow fault, correct the blockage and press the on/offbuon twice. The elapsed run time

display will reset to 0 when the pump is restarted. If the baery icon is displayed, recharge the baery before sampling.

Displayed Elapsed Run Time - Elapsed run time is displayed continuously on the LCD. For elapsed times after 999

minutes, the display still shows elapsed time but alternates between displaying the first two digits of the elapsed time

and the last three digits. For example, a pump that has run for 1,440 minutes would display first “01” and then “440.”

The display maximum is 99 999, which is 99,999 minutes.

4. At the end of the sampling period, press the on/offbuon and record stop time and other pertinent information.

chek-mate

Calibrator

Sample medium Tygon

tubing

Calibration train with filter cassette

Pump

inlet Suction

port

Clip sample medium

to worker and pump

to belt.

Impinger holder on pump

with impinger and trap

Form 37714 Rev 1809

Page 4 of 13

www.skcinc.com

High Flow Applications (Cont)

5. Cap the sample and send it with blanks and pertinent sampling information to a laboratory for analysis.

6. Verify the flow.

a. Turn on the pump and reinstate the calibration train and sample medium.

b. Take three readings and record the average value as the post-sample flow rate. Do not adjust the pump flow rate during this step.

c. Compare the pre and post-sample flow rates. Note in sampling documentation if the values differ by more than ± 5%.

Low Flow Applications (5 to 500 ml/min)

• Single-tube sampling requires the All-in-One Low Flow Holder; see the operating instructions for the All-in-One for details on its operation.

• Multiple-tube sampling requires a Constant Pressure Controller (CPC) and a Dual, Tri, or Quad Adjustable Low Flow Tube Holder accessory;

see the operating instructions for the CPC and Adjustable Low Flow Tube Holder for details on their operation.

Using the All-in-One Low Flow Holder (Figure 2)

Set/Calibrate Flow Rate for Single Tube

• Allow pump to equilibrate after moving it from one temperature extreme to another.

• Charge pump battery completely before calibration and sampling.

• Calibrate/verify pump flow rate before and after each sampling operation using the tube holder and

pump to be used for sampling.

• Set the flow rate through the pump first and then calibrate the flow rate through the representative

sorbent tube.

• Two small inlet holes on the bottom of the built-in CPC of the All-in-One can become blocked.

Periodically inspect and, if needed, clean with a small pick and blow particles away with a puff of air.

Pump Flow Rate

1. Ensure that the baery is fully charged and that the pump has run for 5 minutes before

calibrating. Leave the pump running.

2. Prepare the calibrator (see calibrator instructions). Using flexible tubing, connect the calibrator outlet (suction port) to the pump inlet.

3. Set the pump flow rate to 1.5 L/min. Using a small screwdriver, turn the flow adjustment screw on top of the pump (Figure 1), clockwise

to increase flow or counterclockwise to decrease flow, until the calibrator indicates 1.5 L/min.

4. Remove tubing from the pump inlet.

Flow Rate Through Sorbent Tube

1. Aach the Tygon tubing of the All-in-One to the pump inlet. Note: If the pump flow faults shortly after the holder is aached, check that

the needle valve is open by using a small flat-head screwdriver to turn the flow adjust screw on the holder slightly counterclockwise. If flow fault

continues, check that the two small holes on the boom of the built-in CPC are not blocked. If needed, clean them with a small pick and blow any

particles away with a puffof air.

2. Break tips offthe representative sorbent tube and insert it into the rubber sleeve on the All-in-One (arrow on the tube points toward

the holder). Note: Ensure that the sorbent tube fits snugly in the rubber sleeve prior to sampling to avoid air leakage. Two sleeves, each with a

different inner diameter, are supplied with the All-in-One.

3. Using flexible tubing, connect the calibrator outlet to the inlet of the representative sorbent tube in the holder. See calibration train above

right.

In the next step, do not shut off flow completely with flow adjust screw or use an oversize screwdriver to

adjust flow — valve or thread seat damage may result.

4. Do not adjust the flow on the pump. Adjust the flow rate through the representative sorbent tube

using a small flat-head screwdriver to turn the flow adjust screw on the All-in-One (counterclockwise

to increase, clockwise to decrease) until the calibrator displays the method-specified flow rate. Take a

minimum of three readings and record the average flow rate, as per OSHA/NIOSH instructions.

5. When calibration is complete, turn offthe pump by pressing the on/offbuon. Disconnect the calibrator

and tubing from the representative sorbent tube inlet.

Turn screw on holder

to adjust flow.

Flow

adjust

screw

Calibration train with All-in-One

Low Flow Holder connected

to AirChek 52

All-in-One

Tygon

tubing

Pump

inlet

Flow adjust screw

(needle valve)

Suction

port

Form 37714 Rev 1809

Page 5 of 13

www.skcinc.com

Clip tube holder to

worker and pump to belt.

Low Flow Applications (Cont)

Set Up/Sample with Single Tube

• Allow pump to equilibrate after moving it from one temperature extreme to another.

• Protect sample pump from weather when sampling outdoors.

• Use of any device other than the approved battery pack to power the pump voids the UL Listing for intrinsic safety and

any warranty.

• Charge pump completely before calibration and sampling.

• Calibrate/verify pump flow rate before and after each sampling operation using the tube holder and pump to be used for

sampling.

1. Replace the representative sorbent tube used for calibrating flow with a new unexposed sorbent tube for

sample collection. Note: Ensure sorbent tube fits snugly in rubber sleeve of the All-in-One before sampling to avoid

any air leakage. Two sleeves, each a different inner diameter (ID), are supplied.

2. Place the tube cover over the tube (Figure 2) and thread it into place on the All-in-One low flow holder.

3. Place the sorbent tube where appropriate for sampling. For personal sampling, clip the sample medium to

the worker in the breathing zone and the pump to the worker’s belt.

4. Press the on/offbuon to clear the elapsed time displayed on the LCD and to start sampling. Record the start time and other pertinent

information. The LCD will automatically display elapsed run time. See below.

Possible Displays During Sampling

Flow or Baery Fault Shutdown - If the pump is unable to compensate due to excessive back pressure or a low baery

condition exists, it will shut down and timing functions will pause. The LCD will display either a baery-shaped icon

or a flow fault icon () depending on the cause of the shutdown. Upon flow fault, the pump will aempt to restart up

to five times. To restart from flow fault, correct the blockage and press the on/offbuon twice. The elapsed run time

display will reset to 0 when the pump is restarted. If the baery icon is displayed, recharge the baery before sampling.

Displayed Elapsed Run Time - Elapsed run time is displayed continuously on the LCD. For elapsed times after

999 minutes, the display still shows elapsed time but alternates between displaying the first two digits of the elapsed

time and the last three digits. For example, a pump that has run for 1,440 minutes would display first “01” and then

“440.” The display maximum is 99 999, which is 99,999 minutes.

5. At the end of the sampling period, press the on/offbuon and record stop time and other pertinent information.

6. Cap the sample tube and send it with blanks and pertinent sampling information to a laboratory for analysis.

7. Verify the flow.

a. Turn on the pump and reinstate the calibration train and sample media.

b. Take three readings and record the average value as the post-sample flow rate. Do not adjust the pump flow rate during this step.

c. Compare the pre and post-sample flow rates. Note in sampling documentation if the values differ by more than ± 5%.

Figure 2. All-in-One Low Flow Holder Connected to AirChek 52

in One Low Flow Holder Conn

Flow adjust screw

(needle valve)

Threaded fitting All-in-One

rubber sleeve

Built-in CPC

Tygon tubing

Pump

inlet

Form 37714 Rev 1809

Page 6 of 13

www.skcinc.com

Low Flow Applications (Cont)

Using a CPC and Dual, Tri, or Quad Adjustable Low Flow Tube Holder (Figure 3)

Set/Calibrate Flow Rate for Multiple Tubes

• Requires Constant Pressure Controller (CPC) and Adjustable Low Flow Tube Holder (see Accessories). The low flow tube holder used with CPC

allows up to four tube samples to be taken simultaneously, each at different flow rates if desired.

• Allow pump to equilibrate after moving it from one temperature extreme to another.

• Charge pump battery completely before calibration and sampling.

• Calibrate/verify pump flow rate before and after each sampling operation using the tube holder and pump to be used for sampling.

• Set the flow rate through the pump first and then calibrate the flow rate through each representative sorbent tube.

Pump Flow Rate

Follow these important steps before proceeding.

1. Ensure that the baery is fully charged and that the pump has run for 5 minutes before calibrating. Leave pump running.

2. Prepare a calibrator (see calibrator instructions). Using flexible tubing, connect the calibrator outlet (suction port) to the pump inlet.

3. Calculate the sum of all tube flow rates. The maximum flow rate through any one tube is 500 ml/min.*

a. If the sum is ≤1000 ml/min, set the pump flow rate to 1.5 L/min.

b. If the sum is > 1000 ml/min, multiply that number by 0.15 and total the two numbers. Set the pump flow rate for the resulting

new sum. (Example: Sampling with three sorbent tubes, each with a flow rate of 500 ml/min.* The sum of the tube flow rates is

calculated as 3 x 500 = 1500. Determining a 15% higher flow rate is calculated as 1500 x 0.15 = 225. Calculating the final pump

flow seing would be 1500 + 225 = 1725 ml/min.)

* Back pressure across some sample tubes can be higher than average. In these instances, the maximum flow rate of 500 ml/min per tube may not

be achieved.

4. Using a small screwdriver, turn the flow adjustment screw on top of the pump (Figure 1) (clockwise to increase flow or counterclockwise

to decrease flow) until the calibrator indicates the required flow rate.

5. Remove tubing from the pump inlet and calibrator outlet.

Figure 3. Quad Adjustable Low Flow Tube Holder

Top view of flow

adjust screws

Anti-tamper cover

Low flow holder outlet

Sorbent sample tube

Rubber sleeve

Clothing clip

Flow adjust screws

Protective cover

Form 37714 Rev 1809

Page 7 of 13

www.skcinc.com

Flow Rate Through Sorbent Tubes

1. Aach the tubing on the CPC outlet (side of the CPC without a label) to the pump inlet. Aach

the Adjustable Low Flow Holder to the CPC inlet (marked “To Sample”). See Figure 4.

2. Break tips offthe representative sorbent tubes and insert the tubes into the rubber sleeves on

the holder (arrow on each tube pointing toward pump). Place unopened tubes in any unused

ports to “seal” them.

3. Label all representative tubes and ports.

4. Using flexible tubing, connect the exposed end of the first active tube to be calibrated to the

calibrator outlet (suction port).

5. Using a small screwdriver, loosen and turn the brass flow adjust screw (see above right)

directly beneath the port holding the first active tube to be calibrated (clockwise to increase,

counterclockwise to decrease) until the calibrator indicates the method-specified flow rate. Do

not adjust the flow rate on the pump. Note: For tri and quad models, first rotate each anti-tamper

cover to expose the flow adjust screws, then adjust the appropriate one until the calibrator indicates the

desired flow (Figures 3 and 5).

6. Repeat Steps 4 and 5 for each active representative tube. Note: Changing the flow on one tube will

not affect the flow rate through the remaining tubes.

7. Once flow is calibrated for each active tube, it is recommended practice to re-check the flow rate

through representative tubes before removing them. Any adjustment should be minimal.

Screw Screw

Figure 5. Cut-away of Tri/Quad

Adjustable Low Flow Tube Holder

Turn screw on

tube holder to

adjust flow.

Flow adjust screws

Connect

CPC to

pump inlet,

tube holder

to CPC, and

tube inlet to

calibrator.

Figure 4. Calibration Train with Quad Adjustable

Low Flow Tube Holder

Suction port

chek-mate Calibrator

Quad tube holder

Tube holder outlet

Pump

inlet

CPC inlet (marked

“To Sample”)

Form 37714 Rev 1809

Page 8 of 13

www.skcinc.com

Set Up/Sample with Multiple Tubes

• Requires Constant Pressure Controller (CPC) and Adjustable Low Flow Tube Holder (see Accessories). The low flow tube holder used with CPC

allows up to four tube samples to be taken simultaneously, each at different flow rates if desired.

• Allow pump to equilibrate after moving it from one temperature extreme to another.

• Protect sample pump from weather when sampling outdoors.

• Use of any device or battery pack other than P85004 or P84002 to power the pump voids the UL Listing for intrinsic safety.

• Charge pump completely before calibration and sampling.

• Calibrate/verify pump flow rate before and after each sampling operation using the tube holder and pump to be used for

sampling.

1. Replace the representative sorbent tubes used for calibration with new unexposed sorbent tubes for sample

collection.

2. Place a protective tube cover over each tube and thread into place on holder until secure.

3. Place the adjustable holder with tubes where appropriate for sampling. For personal sampling, clip the low

flow tube holder to the worker in the breathing zone and the pump to the worker’s belt.

4. Press the on/offbuon to clear the elapsed time displayed on the LCD and to start sampling. Record the start time

and other pertinent information. Sample for the time specified in the method used. The LCD will automatically

display elapsed run time.

Possible Displays During Sampling

Flow or Baery Fault Shutdown - If the pump is unable to compensate due to excessive back pressure or a low baery

condition exists, it will shut down and timing functions will pause. The LCD will display either a baery-shaped icon

or a flow fault icon () depending on the cause of the shutdown. Upon flow fault, the pump will aempt to restart up

to five times. To restart from flow fault, correct the blockage and press the on/offbuon twice. The elapsed run time

display will reset to 0 when the pump is restarted. If the baery icon is displayed, recharge the baery before sampling.

Displayed Elapsed Run Time - Elapsed run time is displayed continuously on the LCD. For elapsed times after 999

minutes, the display still shows elapsed time but alternates between displaying the first two digits of the elapsed time

and the last three digits. For example, a pump that has run for 1,440 minutes would display first “01” and then “440.”

The display maximum is 99 999, which is 99,999 minutes.

5. At the end of the sampling period, press the on/offbuon and record stop time.

6. Cap the sample tubes and send with blanks and pertinent sampling information to a laboratory for analysis.

7. Verify the flow.

a. Turn on the pump and reinstate the calibration train and sample media.

b. Take three readings and record the average value as the post-sample flow rate. Do not adjust the pump flow rate during this step.

c. Compare the pre and post-sample flow rates. Note in sampling documentation if the values differ by more than ± 5%.

Clip tube holder to

worker and pump

to belt.

Form 37714 Rev 1809

Page 9 of 13

www.skcinc.com

Battery pack

release arms

Battery pack

Security screws

in out position

Maintenance

Replace the Pump Inlet Filter

The AirChek 52 Sampler is fied with a filter/trap just below the pump inlet. This prevents particles from

being drawn into the pump mechanism. The filter should be replaced periodically as follows:

1. Grip the inlet fiing (see right) and turn it counterclockwise to unthread it.

2. Holding the pump upside down, use a small flat-head screwdriver or tweezers to remove the filter.

3. Place a new filter in the inlet. Ensure that the rubber gasket inside the inlet fiing is still in place.

4. Thread the inlet fiing back into place.

Replace the Battery Pack

Use of a repaired or rebuilt battery pack voids any warranty and the UL Listing for intrinsic safety.

1. Loosen two security screws on boom of pump case and allow them to fall to the out position.

2. Pinch baery pack release arms and pull the boom half of the pump case away from

the top half.

3. Align arms on top half of case with slots on either side of the new baery pack

housing. Ensure that the back of the baery pack with the charging jack is on the

same side as the belt clip.

4. Slide baery pack up until arms click into place.

5. Push each security screw into the baery pack housing and tighten.

Once installed, completely charge the new battery pack before operating the pump (see Charge the Battery Pack). It may be necessary to

charge it a few times before achieving maximum battery capacity.

For information on SKC pump baery packs, visit hp://www.skcinc.com/instructions/1756.pdf.

Pump Service

Pumps under warranty should be sent to SKC Inc. for servicing. See Limited Warranty and Return Policy.

Form 37714 Rev 1809

Page 10 of 13

www.skcinc.com

Accessories/Replacement Parts

Accessories Cat. No.

chek-mate Calibrator with CalChek, 0.50 to 5 L/min, includes 9-volt alkaline battery and

NIST-traceable certificate 375-0550N

Low Flow Sampling

Low Flow (5 to 500 ml/min) Kit includes All-in-One low flow holder and Type A tube cover 210-500

Adjustable Low Flow Tube Holders

Use with CPC listed below. Require separate tube covers listed below

Dual Holder 224-26-02

Tri Holder 224-26-03

Quad Holder 224-26-04

Constant Pressure Controller (CPC) 224-26-CPC

Protective Tube Covers for Sorbent Tubes

Use with adjustable low flow tube holders listed above.

Type A - 6-mm OD x 70-mm L, included in Low Flow Kit above 224-29A

Type B - 8-mm OD x 110-mm L 224-29B

Type C - 10-mm OD x 150-mm L 224-29C

Type D - 10-mm OD x 220-mm L 224-29D

Battery Maintenance

PowerFlex Charging System for SKC Personal Pumps

5-Station, 100-240 V 223-1000

Single, 100-240 V 223-2000

PowerFlex Pump Cable, for AirChek 52 223-1004

Battery Eliminator,* connects pump to line power for extended sampling, 115 V 223-300

Pump Operation

Screwdriver Set, included with pump 224-11

Protective Nylon Pouch with belt and shoulder strap

Black 224-88

High-profile Red 224-96A

Noise-reducing Black 224-96C

* Not UL Listed for intrinsic safety

Form 37714 Rev 1809

Page 11 of 13

www.skcinc.com

Replacement Parts

Use only SKC-approved parts to ensure reliable performance. Failure to do so voids the UL Listing

for intrinsic safety and any warranty.

Use of a repaired or rebuilt battery pack voids any warranty and the UL Listing for intrinsic safety.

Failure to follow warnings, cautions, and notes voids any warranty.

Internal Stack

No. Description Cat. No.

1A/1C Stack screws, pk/12 P51891

2Inlet/Hose Connect, includes filter and gasket P20106

2A Replacement Inlet Filter, pk/10 P40370

3Pulsation dampener P2010802

4Stack plate N/A

5A/5B Valve plates (top and bottom) P213201

6Diaphragm/Yoke assembly P2129B

7Pump body P22417G

8Motor/Eccentric P518803

9Pump base plate P20102

Full Stack without Motor P20102A

Parts not indicated in illustration:

N/A PC Board P79592

N/A Screw and O-ring Set (complete for one pump) P22402

External Case

No. Description Cat. No.

1Battery Pack, NiMH P78011AMH

2Battery Pack Release Arms N/A

3Battery Pack Security Screws N/A

4Compensation Pot A N/A

5Compensation Pot B N/A

6Power Plug for Battery Pack, pk/5 P20107

7Charging Jack (on rear of battery pack) N/A

8Impinger Holder Mounting Screws N/A

9Inlet (includes filter and gasket) P20106

10 Control Cover P20105

11 Flow Adjustment Screw N/A

12 Power Switch (on/off) N/A

13 Belt Clip (not shown) P20104

14 LCD P72391

15 External Case P2010003

SKC Limited Warranty and Return Policy

SKC products are subject to the SKC Limited Warranty and Return Policy, which provides SKC’s sole liability and the buyer’s exclusive

remedy. To view the complete SKC Limited Warranty and Return Policy, go to hp://www.skcinc.com/warranty.

1A

2A

8

9

2

3

4

7

5A

5B

6

1B

1C

7

AIRCHEK

®

52

10

3

9

14

12

8

2

1

2

4

5

6

11

Bottom of pump

without battery pack

3

15

13

Form 37714 Rev 1809

Page 12 of 13

www.skcinc.com

Appendix

Performance Profile

Flow Range 1000 to 3000 ml/min

5 to 500 ml/min requires low flow accessories. See Accessories.

Flow Control Holds constant flow to ± 5% of set-point after calibration

Compensation Range

(back pressure capability)

1000 ml/min up to 25 inches water back pressure

2000 ml/min up to 25 inches water back pressure

2500 ml/min up to 20 inches water back pressure

3000 ml/min up to 15 inches water back pressure

Typical Back Pressure of

Sampling Media

(inches water)

Flow Rate (L/min) 1.0 1.5 2.0 2.5

Filter/Pore Size (μm)

25-mm MCE/0.8 6 9 12 15

25-mm MCE/0.45 14 22 28 35

37-mm MCE/0.8 2 3 4 5

37-mm PVC/5.0 1 1 2 2

Compare the information in this table to pump compensation range to determine appropriate applications.

Run Time Nickel-metal hydride (NiMH) battery: 12 hrs minimum at 2000 ml/min and up to 25 inches

water back pressure; depends on media used. See Table 1.

Battery Eliminator: Pump provides extended runs.

Power Supply Rechargeable 4.8-V NiMH battery pack, 3.3-Ah capacity

A Battery Eliminator is available (see Accessories); use voids the UL Listing for intrinsic safety.

Battery Charging Time

(varies with battery capacity

and level of discharge)

6 to 8.5 hrs with PowerFlex charger

Temperature Operating: 32 to 104 F (0 to 40 C)

Storage: -4 to 113 F (-20 to 45 C)

Charging: 50 to 113 F (10 to 45 C)

Humidity 0 to 95% non-condensing

Flow Fault If the pump is unable to compensate for longer than 15 seconds due to excessive back pressure, the pump

enters flow fault. During flow fault, the pump stops, the fault icon appears on the display, and elapsed

time remains on the display. Auto-restart is attempted up to 5 times. Note: Elapsed time information

will be lost on restart.

Low Battery Fault LCD displays low battery icon and pump shuts down. LCD remains on.

Time Display LCD shows elapsed pump run time in minutes up to 99,999.

Note: Older pump models display elapsed time up to three digits (999) and then roll back to zero.

LCD Indicator LCD always remains on. Displayed elapsed run time information resets when pump is started.

Noise Level 62.5 dBA* - pump without case

55 dBA* - pump housed in noise-reducing case (optional accessory Cat. No. 224-96C, see Accessories)

* Measured 3 ft (1 m) from pump operating at 2 L/min with a 37-mm, 0.8-μm MCE filter cassee

RFI/EMI Shielding 27 to 1000 MHz

Intrinsic Safety UL Listed for Intrinsic Safety: Class I, Division 1 and 2, Groups A, B, C, D; Class II, Division 1 and 2,

Groups E, F, G; and, Class III, Temperature Code T3C. ATEX-approved models available. Contact SKC.

Dimensions 5 x 3 x 1.75 in (12.7 x 7.6 x 4.4 cm)

Weight 20 oz (567 grams)

Multiple-tube Sampling Requires additional accessories to sample with up to four sorbent tubes simultaneously at flows from

5 to 500 ml/min, dependent on back pressure. See Accessories.

Tubing Requires 1/4-inch ID tubing

Certifications • Intrinsic safety: UL Class I, Groups A, B, C, and D; Class II, Groups E, F, and G; Class III hazardous

locations when used with SKC battery pack model P78011AMH (SKC Cat. No. P78011AMH)

• CE marked

• ATEX-approved models available

Form 37714 Rev 1809

Page 13 of 13

www.skcinc.com

Mixed Cellulose (MCE) filter, 0.8-μm pore size

Flow Rate (L/min)

Filter Diameter

37 mm 25 mm

2.0 40 37

2.5 38 29

3.0 34 25

Polyvinyl Chloride (PVC) filter, 5.0-μm pore size

Flow Rate (L/min)

Filter Diameter

37 mm 25 mm

2.0 56 47

2.5 48 41

3.0 42 38

Table 1. Pump Run Time in Hours with NiMH Battery

Appendix (Cont)

Typical Run Times

Table 1 contains the typical run times achieved when using a fully charged NiMH baery pack. Data is sorted by type of sample media.

All run times are listed in hours. Results are obtained using a new pump and new fully charged baery. Pump performance may vary.

Increases in back pressure during sampling due to buildup of sample on the filter can decrease baery life.

Other manuals for AirChek 52

1

Table of contents

Other SKC Water Pump manuals

SKC

SKC AirChek2000 User manual

SKC

SKC AirChek XR5000 User manual

SKC

SKC AirChek 220-3100 User manual

SKC

SKC AirChek TOUCH 220 Series User manual

SKC

SKC AirChek Connect User manual

SKC

SKC Flite4 User manual

SKC

SKC Leland Legacy User manual

SKC

SKC Flite 3 User manual

SKC

SKC 224-PCXR8M User manual

SKC

SKC 220 Series User manual

SKC

SKC AirChek ESSENTIAL User manual

SKC

SKC 224-PCXR8 User manual

SKC

SKC BioLite Plus 228-9620 User manual

SKC

SKC Leland Legacy User manual

SKC

SKC 210-1002MTX User manual

SKC

SKC AirChek XR5000 User manual

SKC

SKC Flite 2 User manual

SKC

SKC QuickTake 30 User manual

SKC

SKC AirLite 110-100-T User manual

SKC

SKC Vac-U-Go 228-9605 User manual