8 EN

6. Operation

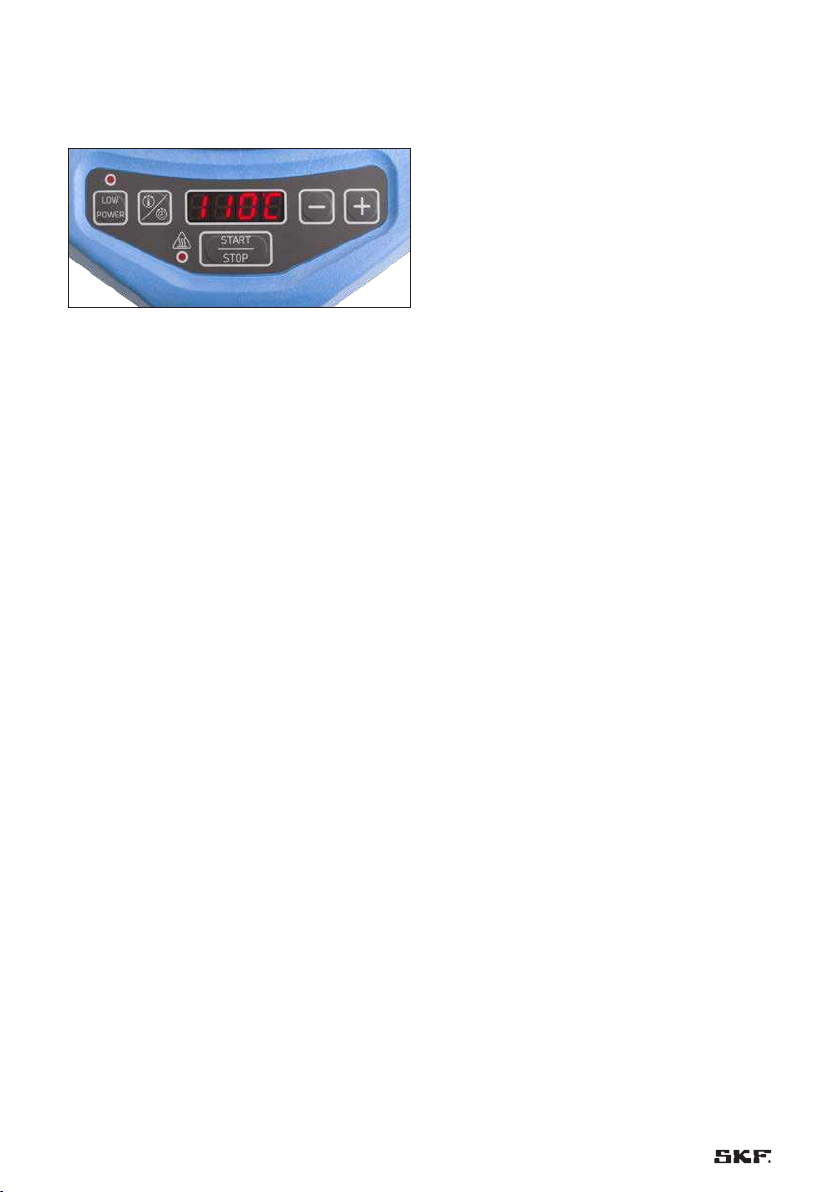

6.1 User interface

Fig. 2 – User interface

From left to right:

• The LOW POWER button and LED.

This button reduces the power of the heater by

half of what it would normally take.

If low power mode is selected, then the red LED

is switched on.

• The temperature/time symbols button is the

MODE button. This button shifts in between

Temperature Mode and Time Mode.

• LED display. The process information is

displayed here: goal temperature, actual

temperature, error codes, time, etc.

• MINUS and PLUS buttons. These buttons

decrease or increase the value shown on the

LED display.

• START/STOP button and heating LED.

Press to start or stop the heater. The LED

button is permanently ON when the heater is

heating.

6.2 Temperature mode

In this mode components can be heated to a given

temperature.

• If the LED screen shows °C or °F,

Temperature Mode is selected.

• The selected temperature is shown on the

display. The default temperature for bearings

is 110 °C (230 °F). If a different temperature is

desired, press + or – to adjust the temperature

in steps of 1˚. Keep the + or – buttons pressed

for a faster adjustment.

• It may be desirable to heat up bearings or other

components to temperatures above 110 °C

(230 °F) for an increased mounting time or

a tighter interference fit. Consult the bearing

specifications to determine the maximum

permitted temperature. Always ensure that

the bearing does not lock due to an excessive

expansion of the inner ring compared to the

outer ring.

• Make sure that the temperature probe is

mounted on the bearing inner ring flange.

• Press START/STOP to start the heater.

The heating LED will switch on. Even if you

cannot hear it, the component is being heated.

• The user interface displays the temperature

detected by the temperature probe.

• Temperature differences in between top

and bottom might occur. This is due to the

higher influence of the inductive coils on the

bottom part of the component. This effect is

automatically adjusted in the last stages of the

heating.

• During heating, when pressing the MODE

button, the heating time is shown.

• When the selected temperature has been

reached, the bearing is then ready to be taken.

An acoustic signal will be generated for

4 seconds.

• If the component is not removed nor the

process stopped, the temperature holding

feature will maintain the component at

temperature for 10 minutes.

• By removing the temperature probe or

the workpiece, the heating process will

automatically stop. It can also be stopped by

pressing the START/STOP button.

• Remove the workpiece with proper handling

equipment. Do not slide the hot component

over the user interface surface as this will

damage the heater.

• The heater is now ready to heat up another

workpiece with the same settings.