4EN

EU Declaration of Conformity

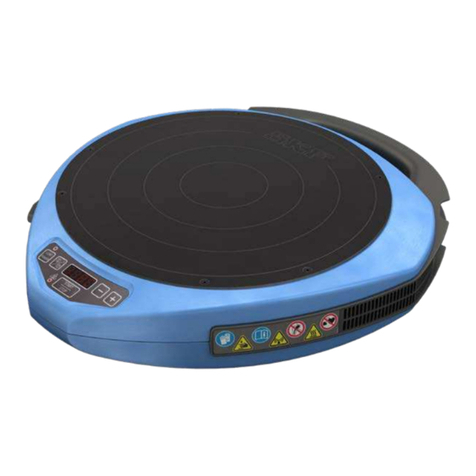

TMBH 5

We, SKF MPT, Meidoornkade 14, 3992 AE Houten,

The Netherlands herewith declare under our sole

responsibility that the products described in these

instructions for use, are in accordance with the

conditions of the following Directive(s):

EMC DIRECTIVE 2014/30/EU

EUROPEAN LOW VOLTAGE DIRECTIVE 2014/35/EU

and are in and are in conformity with the following

standards:

EN 61000-6-2 (2005) + AC (2005)

Industrial (Immunity)

CISPR16-2-3: 2010 + A1:2010 +A2:2014

Class A equipment (Emission)

EN 61000-3-2 (2014), A (Emission)

EN 61000-3-3 (2013) (Emission)

EN 61000-6-4 (2007), A1(2011),

Class A equipment (Emission)

EN 60335-1 (2012): Safety of household and

similar electrical appliances

EN 60519-1: 2020: Safety in installations for

electroheating and electromagnetic processing

RoHS DIRECTIVE (EU) 2015/863 and the

harmonized standard: EN IEC 63000:2018:

EN 50581:2012: Technical documentation for the

assessment of electrical and electronic products with

respect to the restriction of hazardous substances.

Houten, The Netherlands, April 2023

Guillaume Dubois

Manager Quality and Compliance

UK Declaration of Conformity

TMBH 5

We, SKF MPT, Meidoornkade 14, 3992 AE Houten,

The Netherlands herewith declare under our sole

responsibility that the products described in these

instructions for use, are in accordance with the

conditions of the following Directive(s):

Electromagnetic Compatibility Regulations 2016

(2016 No. 1091)

Electrical Equipment (Safety) Regulations 2016

(2016 No. 1101)

and are in and are in conformity with the following

standards:

EN 61000-6-2 (2005) + AC (2005)

Industrial (Immunity)

CISPR16-2-3: 2010 + A1:2010 +A2:2014

Class A equipment (Emission)

EN 61000-3-2 (2014), A (Emission)

EN 61000-3-3 (2013) (Emission)

EN 61000-6-4 (2007), A1(2011),

Class A equipment (Emission)

EN 60335-1 (2012): Safety of household and

similar electrical appliances

EN 60519-1: 2020: Safety in installations for

electroheating and electromagnetic processing

The Restriction of the Use of Certain Hazardous

Substances in Electrical and Electronic Equipment

Regulations 2012 (2012 No. 3032) and the

harmonized standard: EN IEC 63000:2018:

Technical documentation for the assessment of

electrical and electronic products with respect to the

restriction of hazardous substances.

The person authorised to compile the technical

documentation on behalf of the manufacturer is

SKF (U.K.) Limited, 2 Canada Close, Banbury,

Oxfordshire, OX16 2RT, GBR.

Houten, The Netherlands, April 2023

Guillaume Dubois

Manager Quality and Compliance