7SKF TIH L MB

1.3 Distinguishing features

• Inductive coil

When heated the workpiece is located at the same position on the core as the

inductive coil. This design improves efficiency, resulting less power consumpton

and faster heating which reduces the costs to heat each workpiece.

• High efficiency

With its advance power electronics and induction coils design, the TIH L MB has a low

power consumption which represents a high energy savings.

• Remote control panel

To improve the ease of use and to help reduce the risk of contact with the hot

workpiece during operation, the TIH L MB heater is supplied with a remote control

panel which can be detached from the heater.

• Sliding yoke

To facilitate the handling of the yoke while placing the workpiece around it or around

the induction coil, the TIH L MB is fitted with a sliding arrangement for the yoke. See

the illustrations at the beginning of this manual.

• Folding workpiece supports

To support large workpiece when positioned horizontally around the induction coil,

the TIH L MB induction heater is provided with two supports.

See the illustrations at the beginning of this manual.

2. Description

The operation of the heater is controlled by the internal electronics in either of two modes.

The operator can either select the desired temperature of the workpiece in

TEMP MODE or set the length of time that the workpiece will be heated in TIME MODE.

The power level can be adjusted to 100% or 50% for slower heating of sensitive workpieces

(for example, materials like aluminum or brass).

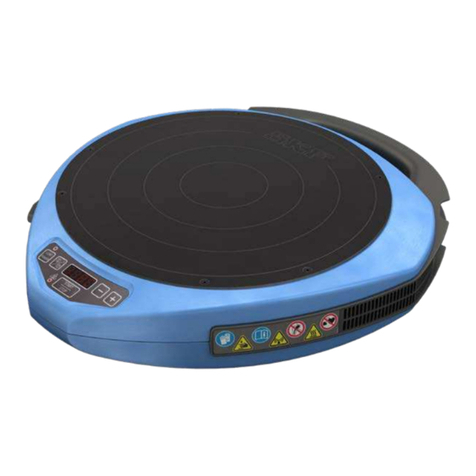

2.1 Components

The TIH L MB induction heater contains a U-shaped iron core with one induction coil.

Workpiece supports are delivered to be mounted on the heater. A detachable remote

control panel is included. The remote control electronics and the internal electronics,

control the operation of the heater. A sliding yoke allows the workpiece to be placed onto

the heater. A temperature probe is included with the heater. Heat-resistant gloves are also

included.

English