3EN

Safety recommendations

• There is a risk of electric hazard. Only qualified

and adequately trained personnel must be

allowed to operate the equipment.

• Due to the magnetic field, during the heating

process observe a safety distance of 1,5 m

(4.9 ft) with the induction heater. People

wearing cardiac pacemakers or having implants

must observe a safety distance of at least

5 meters (16 ft) from the induction heater

during operation. Electronic equipment, such as

wristwatches, mobile phones; but also magnetic

cards or industrial electrical equipment may

also be affected.

• Use proper handling equipment when lifting

heavy workpieces. Secure the workpiece with

appropriate lifting and handling equipment

while heating.

• Avoid contact with hot surfaces.

Always use heat resistant gloves.

• Never modify the heater. All repair work should

be carried out by an SKF repair shop.

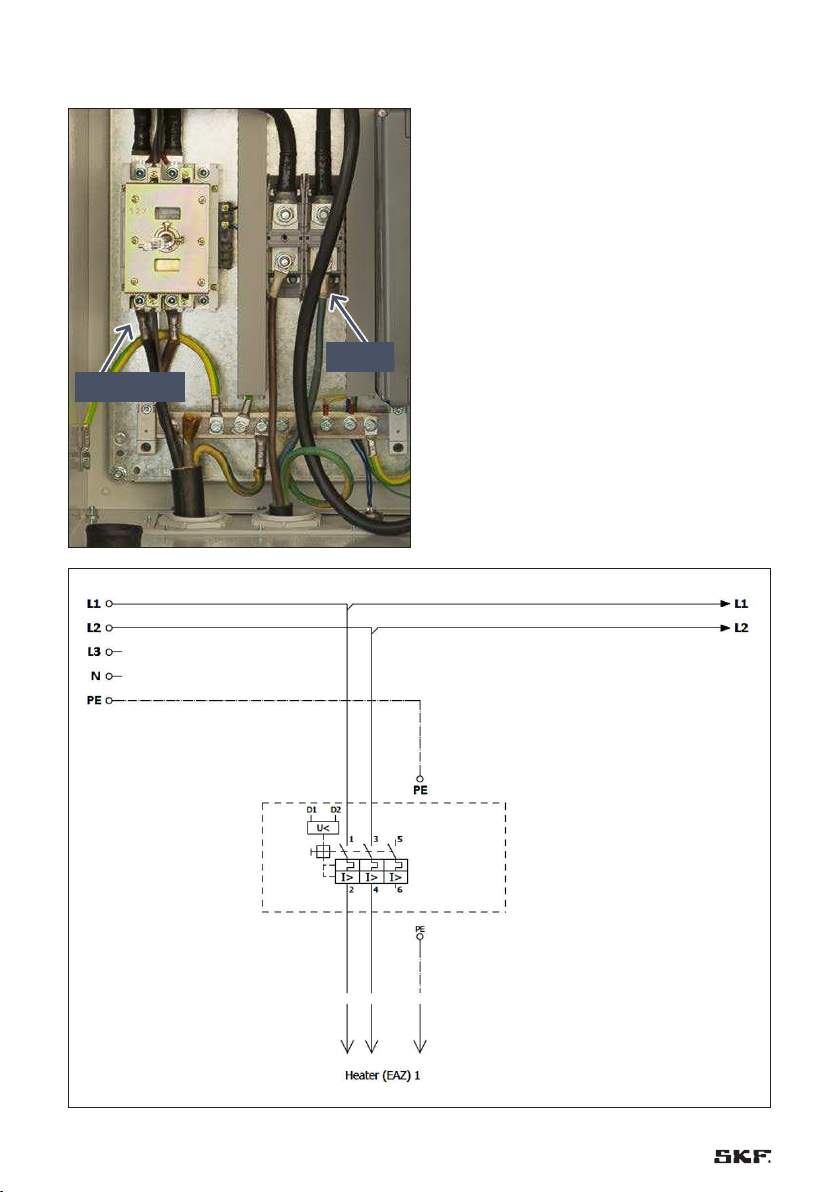

• Make sure the supply voltage is correct.

Connecting the induction heater to the wrong

voltage supply will void the warranty and

probably damage the heater.

• Always make sure the heater is securely

connected to earth.

• Do not expose electronic components to high

humidity or water.

• Never introduce body parts into the bore of the

heater during operation.

• Do not use the equipment in case of damage

or heavy wear is detected on the heating coil.

Also, cracked rings must not be heated with the

electrical induction heater.

• The heater should not be used in areas where

there is a risk for explosion.

• Follow the operating instructions at all times.

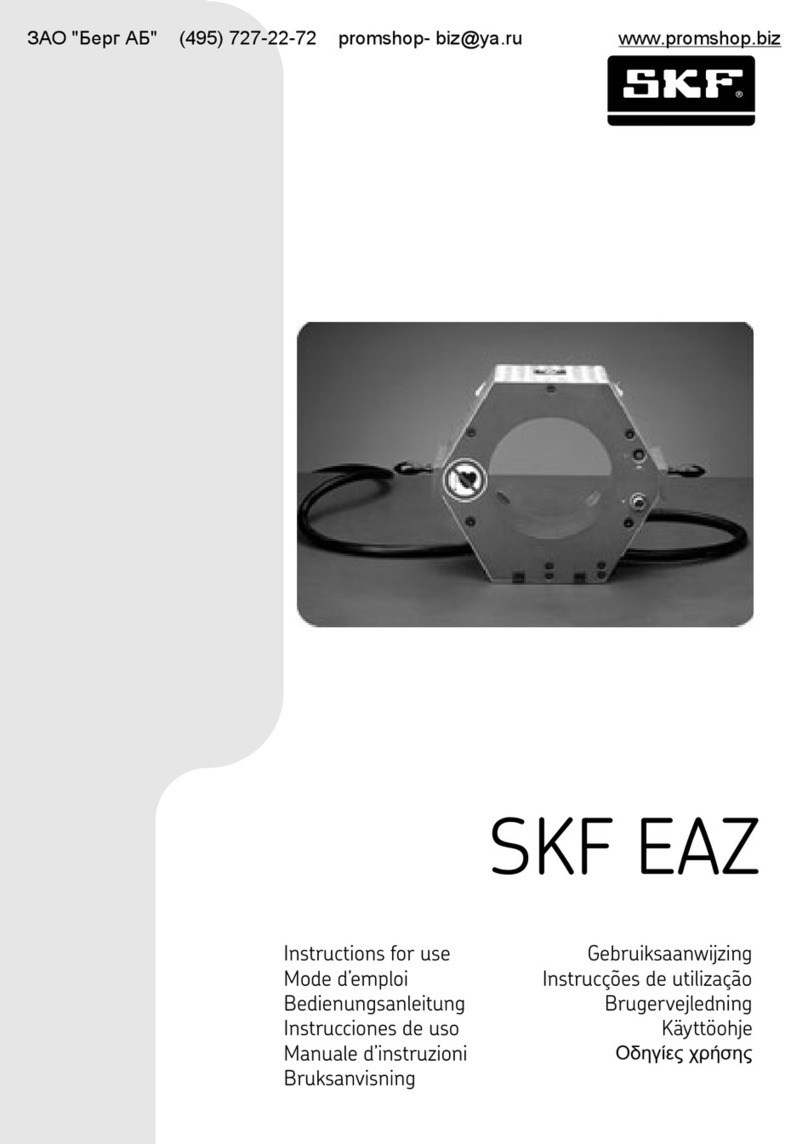

• The EAZ and EAZ CC are solely intended to heat

up bearing rings, mill rolls and labyrinth rings. It

is not intended to heat up any other component.

• The heater needs to be operated by

professionally trained people.

Do not leave the heater unattended.

Especially when using time mode.

• In case of fire, do not use water nor powder-

based extinguisher. This will damage the

electronics. A CO2based extinguisher is

recommended, if available.

• Be aware that fumes coming from the heated

element might occur.

EC Declaration of conformity

We, SKF Maintenance Products, Meidoornkade 14,

3992 AE Houten, The Netherlands herewith declare

that the products described in these instructions

for use, are in accordance with the conditions of the

following directive:

EMC DIRECTIVE 2014/30/EU and are in conformity

with the following standards:

EN61000-6-1:2007

EN61000-6-3:2007 / A1:2011 / AC:2012

EN61000-3-2:2014

EN61000-3-2:2013

EN61000-4-2

EN61000-4-3

EN61000-4-4

EN61000-4-5

EN61000-4-6

EN61000-4-8

EN61000-4-11

EUROPEAN LOW VOLTAGE DIRECTIVE 2014/35/EU

EUROPEAN ROHS DIRECTIVE 2011/65/EU

Houten, The Netherlands, February 2019

Sébastien David

Manager Product Development and Quality