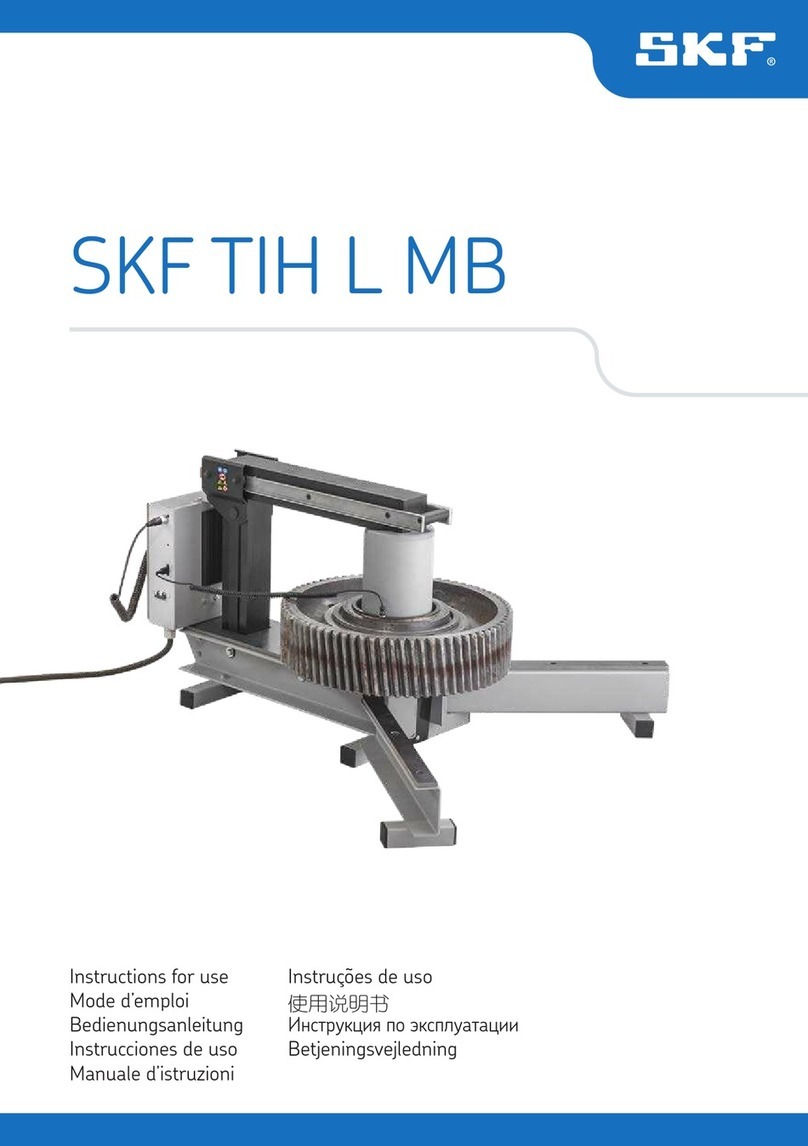

2.2 Technical Data

TIH 220m/xx

Voltage (±10%): TIH 220m/MV: 400-460V / 50-60Hz

TIH 220m/LV: 200-240V / 50-60Hz

Recommended line protection:

TIH 220m/MV minimum requirement 25 A

TIH 220m/LV minimum requirement 50 A

Power consumption (maximum) 10,0-11,5 kVA for 400-460 V

Temperature control 0-250 °C (32-482 °F); in steps of 1°

Probe type thermocouple, K type

Probe maximum temperature 250 °C (482 °F)

Time mode 0-60 minutes; in steps of 0.1 minute

Power range 100%- 50%

Demagnetisation automatic; residual magnetism <2A/cm

Overall dimensions (w x d x h) 750 x 290 x 440 mm

(29,5 x 11,4 x 17,3 in)

Area between supports(width x height) 250 x 255 mm (9,8 x 10,0 in)

Coil diameter 140 mm (5,5 in)

For minimum bearing bore diameter of

150 mm (5,9 in)

Weight (with yokes) 86 kg (189 lbs)

Workpiece maximum weight Bearing: 300 kg (661 lbs)

Solid component: 150 kg (330 lbs)

Maximum heating temperature approx. 400 °C (752 °F)

m20* 220 kg (bearing 23172)

Standard yoke dimensions: For minimum bearing bore diameter of:

70 x 70 x 430 mm (2,8 x 2,8 x 16,9 in) 100 mm (3,9 in)

40 x 40 x 430 mm (1,5 x 1,5 x 16,9 in) 60 mm (2,3 in)

* m20 represents the weight (kg) of the heaviest SRB 231 bearing that can be heated from

20 to 110 °C (68 to 230 °F) in 20 minutes.

3. Installation of the mains plug

A qualied electrician must install a suitable mains plug. The correct supply voltage is

shown in section 2.2.

The wires should be connected as follows:

TIH 220m/MV, TIH 220m/LV with 200V-3 phases, and all other three phases supply

execution

Colour of TIH 220m/xx wire Mains supply terminal

yellow / green ground

blue phase 1

brown phase 2

Connect the TIH 220m to only two of the three phases.