To prime system

Supply lines

After pump reservoir has been filled with

recommended lubricant, remove all plugs in

dead ends of injector manifolds and supply

lines. Turn vent plug in pump counter-

clockwise one complete turn. Operate pump

until lubricant flows freely from vent plug

opening to expel air pockets trapped

between pump and supply line connection.

Tighten vent plug. Continue operating pump

until lubricant flows from any plug opening.

Close opening with plug. Repeat procedure

until all plug openings are closed and supply

lines are primed.

Feeder lines

Fill each feed line with lubricant before

connecting lines to outlet of injectors and

bearings. This will prevent having to cycle

each injector repeatedly to fill feed line

between injector and bearing.

WARNING

Safety unloader requires no adjustment

and should not be tampered with.

Failure to comply may result in death

or serious injury.

Operation

Operation of model pump is fully

automatic, controlled by or volt DC

electric timer and electric operated solenoid

air valve. As truck operates, timer

periodically turns on switch that energizes

solenoid air valve. Solenoid air valve opens,

and admits regulated air to Centro-matic

pump, closing vent valve. Pump begins to

operate, delivering lubricant through supply

lines to each lubricant injector.

As pump builds up pressure, a measured

amount of lubricant is dispensed to bearings

by each injector. After all injectors have

cycled, lubricant pressure rises rapidly to

psi (165 bar) with air regulated to

psi (4 bar), and pump stalls against

pressure.

Timer switch contact is broken, and

solenoid air valve is de-energized, shutting

off air supply; air then exhausts from pump

and vent valve assembly. As air is relieved,

vent valve opens and lubricant pressure in

system vents back through supply line to

lubricant reservoir. Injectors reload, and

system is ready for next lubrication cycle.

Injectors

Check each individual injector for proper

operation.

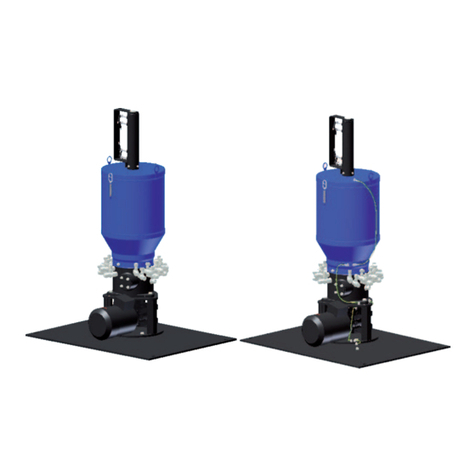

Vent valve

Vent valve () is operated by compressed

air from same source that operates pump.

When pump is in operation, air pressure

keeps vent valve closed and lubricant is

directed through outlet and to injectors.

When air to pump is shut off, vent valve

opens and supply line pressure vents back

into reservoir.

Safety unloader

Safety unloader () is provided at pump

outlet to prevent build up of dangerously

high lubricant pressure in system.

It is factory set to open at approximately

to psi (258 to 293 bar).

Change pump to new

series follower

configuration

Use follower upgrade kit .

Remove bushing (), washer

assembly and retaining ring

() from old follower assembly.

Place follower washer () on lower

side of follower packing (), making

sure top follower washer is still in place.

Place o-ring ()into bushing.

Place gasket () on bushing ().

Place bushing and gasket into assem-

bled follower packing and washers.

Place drops of blue Loctite at

° apart on threads of bushing.

Assemble nut () to bushing

and tighten.

Place hex of bushing in vice and tighten

nut to in-lbs (± in-lbs).