PRODUCT DESCRIPTION 4

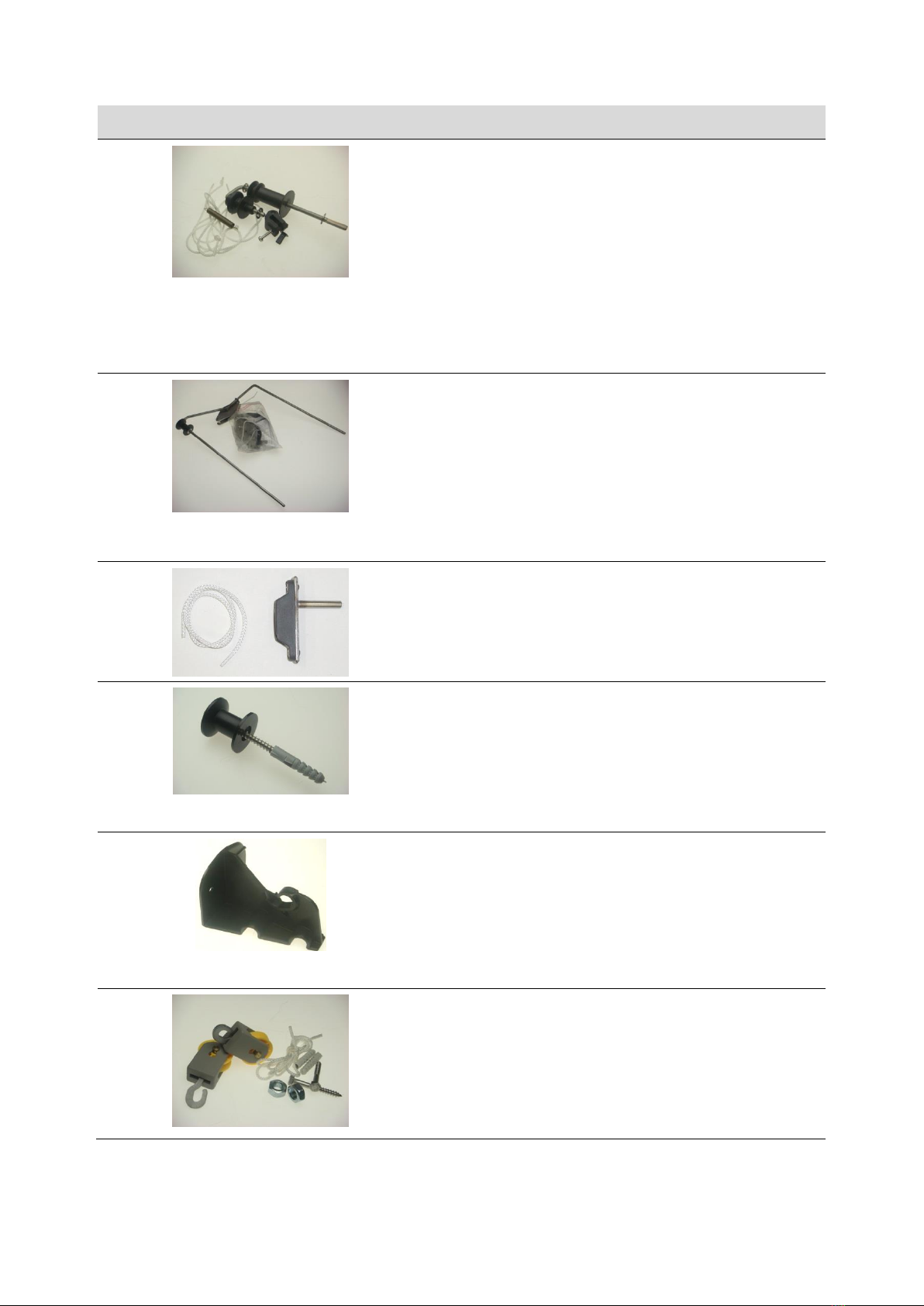

PRODUCT SURVEY 5

1General Drawing of DA 1200 Wall Inlet........................................................... 5

MOUNTING GUIDE 11

2Recommended Tools..................................................................................... 11

2.1 Mounting of sandwich screws..................................................................................12

3Wall Inlet Positioning..................................................................................... 12

4Installation in wall........................................................................................... 12

4.1 Installation in an existing wall or element ...............................................................13

4.2 Building-in the Inlet...................................................................................................13

4.3 Modular System.........................................................................................................15

5Mounting the Regulation Set......................................................................... 16

5.1 Regulation Set with Universal AIC ...........................................................................16

5.1.1 Check the position of the string at advanced inlet control ...........................................................19

5.1.2 Adjustment of wall inlets...............................................................................................................20

5.2 Regulation Set Without Universal AIC.....................................................................21

6Mounting Other Accessories......................................................................... 22

6.1 Extension Piece.........................................................................................................22

6.2 Air Direction Plate .....................................................................................................23

6.3 Baffle Plate.................................................................................................................25

6.4 Regulation set for two Inlets.....................................................................................25

6.4.1 Mounting of Regulation Set for Modular System .........................................................................26

6.5 LPV Door set for Pull rod..........................................................................................26

6.6 Door set for Wire Rope Drive....................................................................................27

TECHNICAL DATA 28

7Dimensioned Sketch...................................................................................... 29

7.1 DA 1200 Wall Inlet .....................................................................................................29

7.2 DA 1200 Light Trap/Outside Flange .........................................................................29

7.3 DA 1200 Inlet Cover...................................................................................................30

7.4 DA 1200 Light Trap for Inlet Cover...........................................................................30

7.5 DA 1200 fly screen for inlet cover ............................................................................31