Technical User´s Guide 5

DA 50-920

2Mounting Guide

2.1 Introduction to the Mounting

Check that all ordered parts are present and intact according to the delivery note before you start your

work.

This chapter concerns the general mounting of the DA 50-920 unit, regardless of the type

of building in which it is to be mounted.

As an appendix at the end of the document, you find supplementary mounting guides,

which define the specific mounting conditions depending on the type of building

concerned.

2.1.1 The Appendixes are divided as follows:

Appendix 1, Mounting Guide, Garret

Appendix 2, Mounting Guide, free hanging Roof

Appendix 3, Mounting Guide, free hanging Ridge

Appendix 4, Mounting Guide, Roof through Garret

Appendix 5, Mounting Guide, Ridge through Garret

Appendix 6, Mounting Guide, Monoblock House

Appendix 7, Mounting Guide, flat Roof

2.2 Placement in the House

Place the DA 50-920 units in the house according to the enclosed drawing; however, the placement

depends on purlins, rafters etc. Contact SKOV A/S if there are considerable deviations.

Place the DA 50-920 units evenly distributed with the same spacing in the whole house. The two units

at each end of the house may be placed proportionally farther from the gable to reduce down draught

along the gable.

Check that all DA 50-920 units can be placed freely in relation to other equipment, which may be

mounted later, such as feed lift, water etc., however, as agreed with the building owner.

NB: Note the diameter of the plates for the DA 50-920 units when lifting them past the feed lift, water

etc.

With using Ø920 ducts, it may be an advantage to increase the distance between purlins/rafters where

the DA 50-920 unit is to be placed, and possibly use a stronger purlin/rafter on each side of the unit,

however, as agreed with the building owner. In case of a renovation, however, this is not possible, and

the unit must be placed in the best possible way.

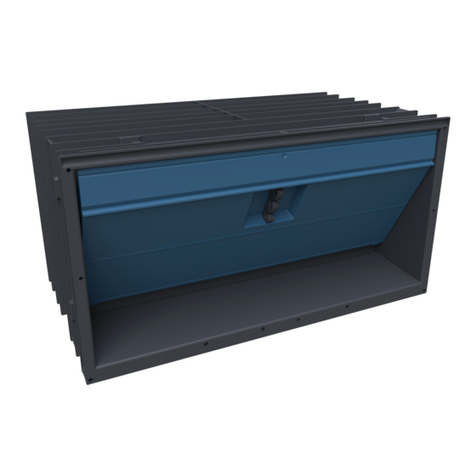

NB: Without affecting the output, the duct can be pressed to a square of c 750 × 750 mm where it

passes purlins/rafters. Use a duct of 1500 mm for this purpose. The duct must be placed so that it is the

middle of the duct, which is placed by the purlins/rafters. Hereafter the duct can be reshaped to

circular form and mounted with the other parts for the unit.

The pull rod must be placed left of the DA 50-920 when you look towards the winch

motor. This also means that you must make sure that the large wire lock of the DA 50-920

funnel tube is to the left.