6Technical User's Guide

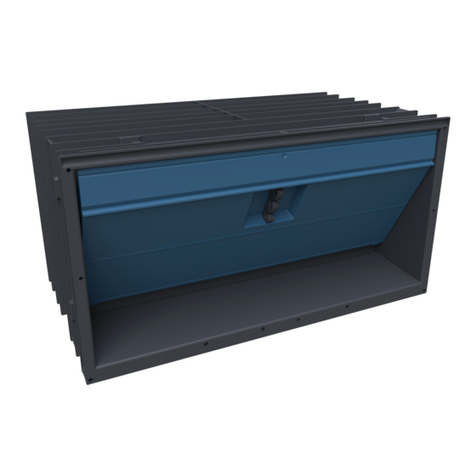

DA 600 Wall Exhaustion

3Installation Guide

For installation of DA 600 wall exhaustion please refer to the wiring diagrams in Instruction for DA

74A winch motor (603701).

NB Installation of fan

Lay the cable from the motor through the wall with the duct and assemble in DA 74 winch

motor. Carry out the cabling so it cannot be affected by rodents.

4Maintenance Instructions

4.1 DA 600 Wall Exhaustion

Normally, the wall exhaustion does not require any maintenance apart from cleaning.

4.2 Guard Net

•Clean them if they show signs of blocking. Only a few mm of dust result in a major increase

of energy consumption.

4.3 Fan

Service and cleaning of the fan are not to be carried out, until the electricity has been

properly switched off.

•Motor and electric installations have been carried out according to the protection class IP54. This

means that high-pressure cleaning against packing surfaces, bearings, etc. is not to take place.

•Clean the fan at regular intervals so the cooling and air can pass unimpededly.

•If dismantling of the fan is required for regular cleaning, it is recommendable to have a long

rubber cable installed, which can be drawn down with the fan. This way, electrical

disassembling can be avoided. An alternative could be to mount an ISO approved connector.

•If service requires dismantling of the fan and there is no long cable connected, the area

around the plug on the motor must be cleaned thoroughly before dismantling the motor.

Subsequently, covering is necessary to ensure that no dirt enters the motor and plug, which

may cause operational problems.

•Check at least once a year if bearings, gaskets, etc. are intact.

•The fan is not to be stopped by placing hard objects between the fan blades, as they will

then be damaged.

•The fan is not to be weighted with more than its own weight.

5Trouble Shooting Instructions

5.1 DA 74

See Trouble Shooting Instructions in the DA 74 winch motor instruction (603701).

5.2 Fan

•If the fan has difficulties in running or shows signs of irregular operation it may be caused

by a defective capacitor. Contact authorized personnel for replacement.

•If a rumbling sound comes from the bearings or the motor gets relatively warm around the

bearings, it may be due to defective bearings. Replacement of bearings should only be done

by authorized personnel.