2 Technical User´s Guide

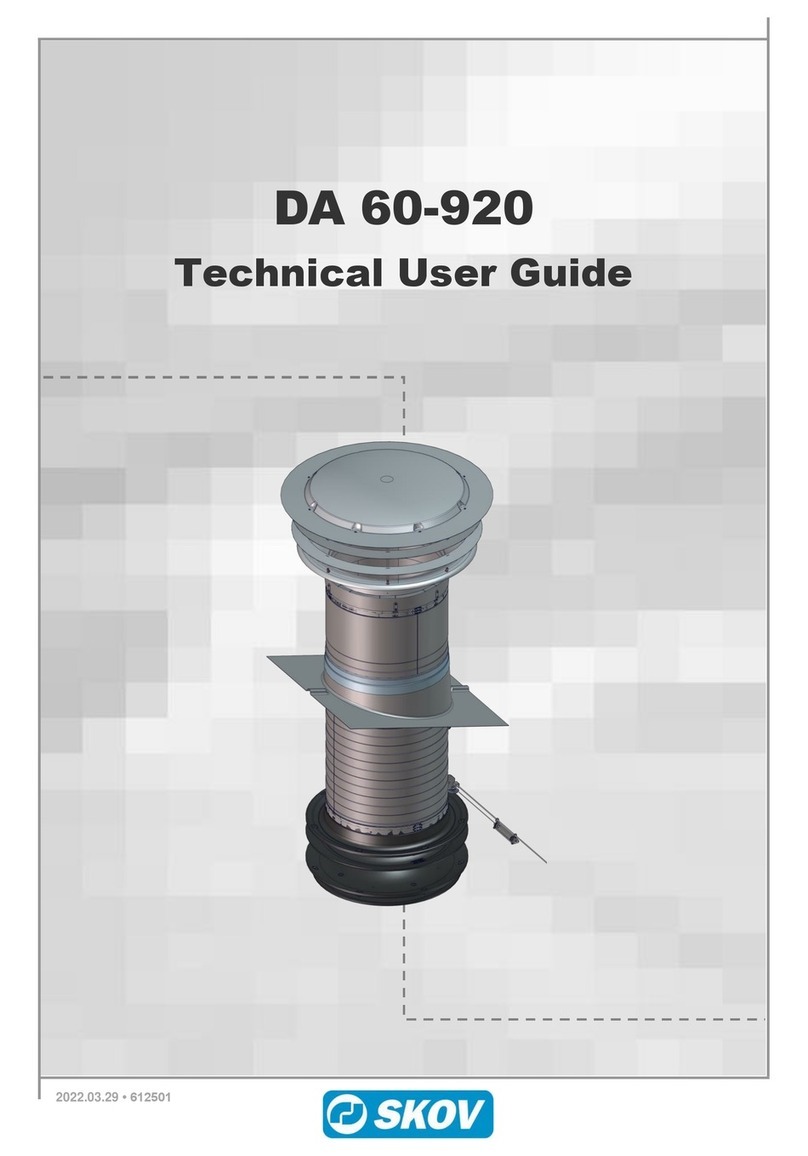

DA 50-650

CONTENTS

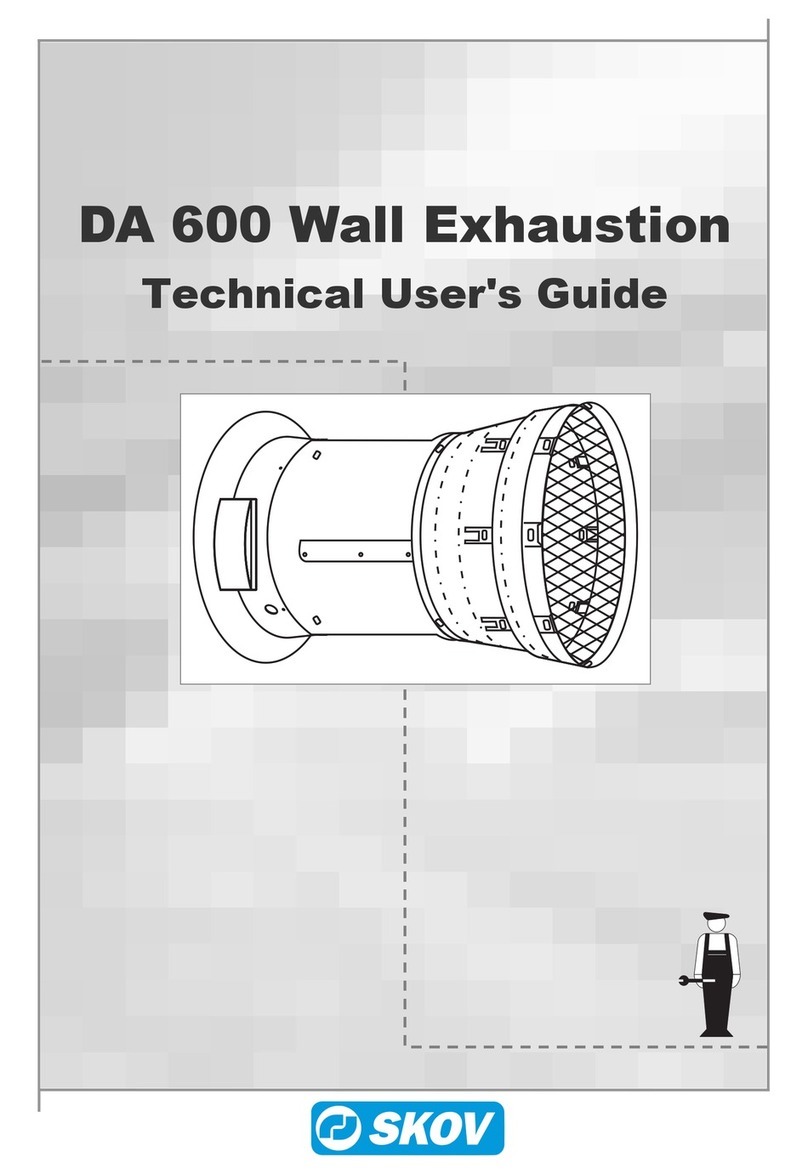

1PRODUCT DESCRIPTION 4

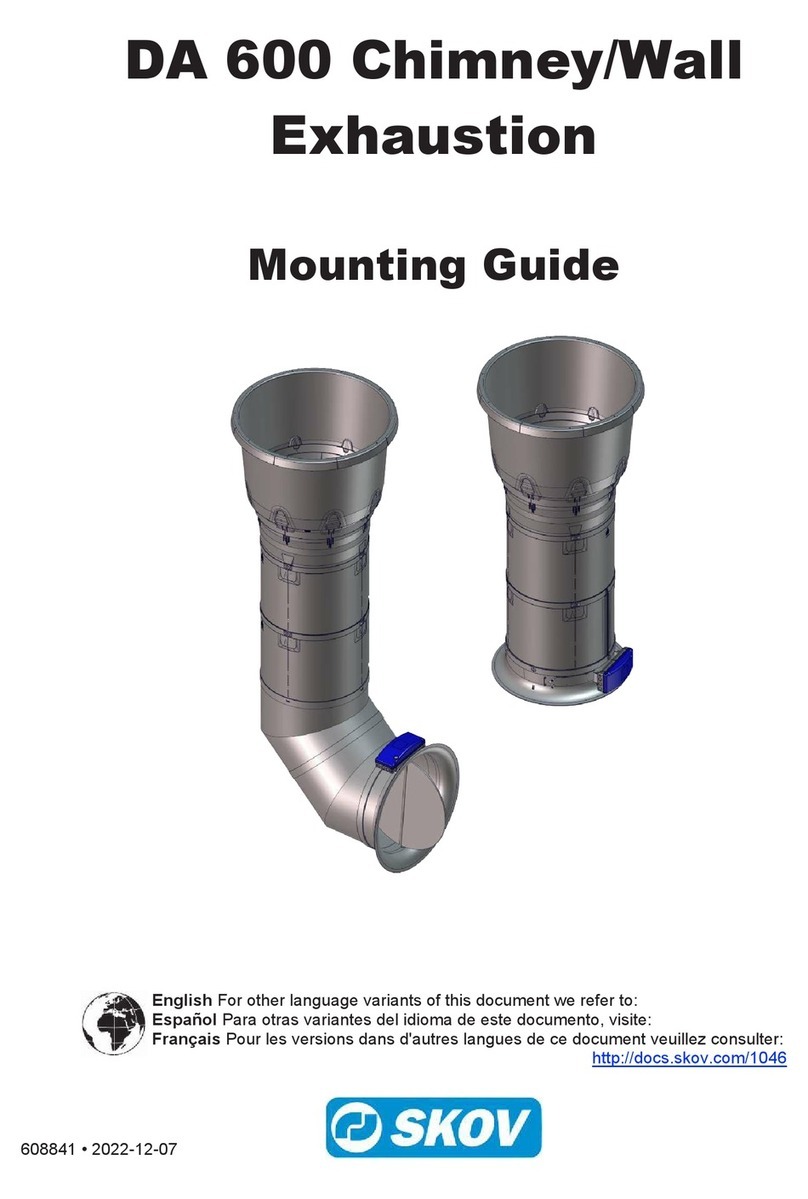

2MOUNTING GUIDE 5

2.1 Introduction to the Mounting............................................................................ 5

2.1.1 The Appendixes are divided as follows:.......................................................................... 5

2.2 Placement in the House.................................................................................... 5

2.2.1 Examples of Placement in the House .............................................................................. 6

2.3 General Mounting.............................................................................................. 7

2.3.1 General Drawings ............................................................................................................. 7

2.3.2 Mounting of Roof Sheet.................................................................................................... 9

2.3.3 Assembling of Ducts.......................................................................................................... 9

2.3.4 Roof Flashing with Neoprene Cloth .............................................................................. 10

2.3.5 Assembling of Duct and Funnel Tube........................................................................... 11

2.3.6 Mounting of Roof Duct on Duct .................................................................................... 11

2.3.7 Mounting of Bell Mouth on Roof Duct ......................................................................... 12

2.3.8 Mounting of Net on Bell Mouth..................................................................................... 12

2.3.9 Mounting of Rain Screen on Net ................................................................................... 12

2.3.10 Mounting of Roof Cap on Net........................................................................................ 13

2.3.11 Mounting of Adjustment Fitting with Spring on the Bottom Plate............................ 13

2.3.12 Mounting of Intermediate Plate (optional equipment) and Bottom Plate ................. 14

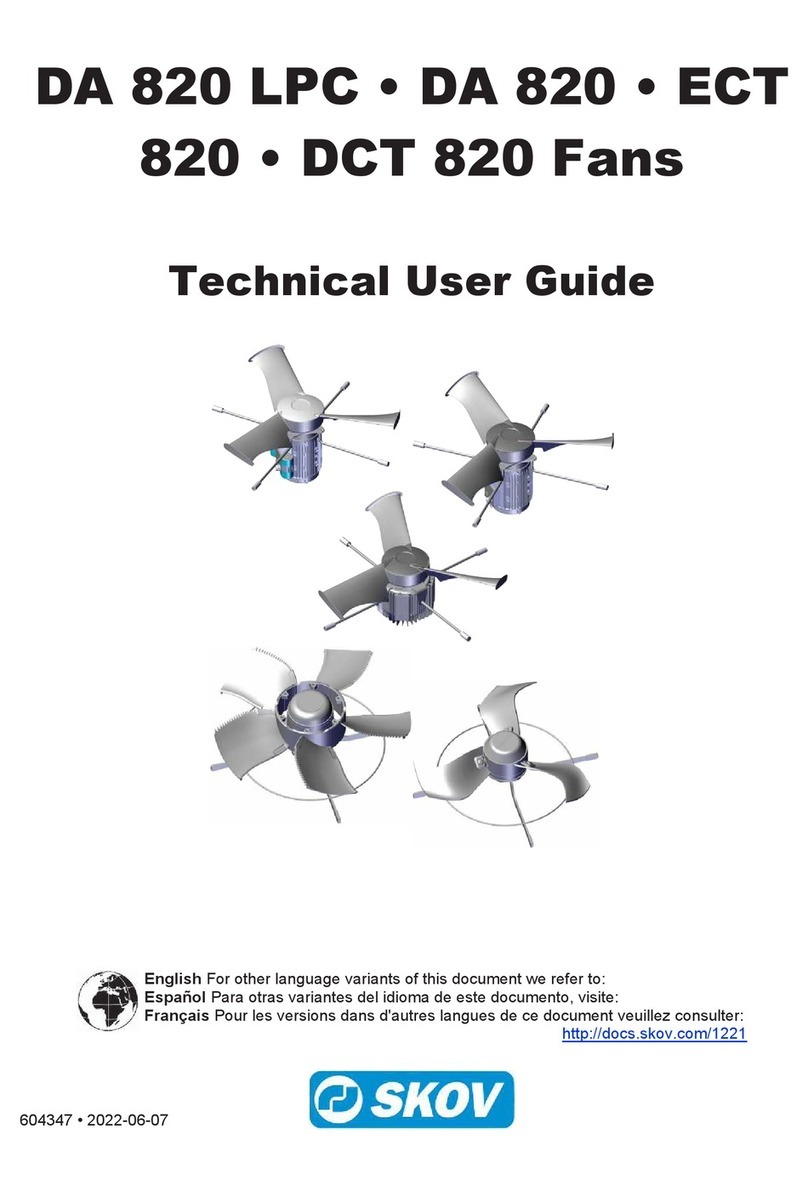

2.3.13 Mounting of Recirculation Fan (optional equipment)................................................. 14

2.3.14 Measuring and Mounting of Pull Rod/Suspension ...................................................... 16

2.3.15 Fastening of Air Supply Unit to Pull Rod..................................................................... 17

2.4 Adjustment of DA 50-650 Air Supply Unit ......................................................18

3INSTALLATION GUIDE 20

3.1 Cable Chart for Recirculation Fan...................................................................20

3.2 Wiring Diagram for Recirculation Fan ............................................................21

3.3 Diagram for Rotating Direction of the Recirculation Fan ..............................22

4USER’S GUIDE 23

4.1 Cleaning............................................................................................................23

4.1.1 Dismantle Bottom Plate and Intermediate Plate for Cleaning ................................... 23

5MAINTENANCE INSTRUCTIONS 23

5.1 Instructions for taking down the Unit and Recycling ....................................23

6TROUBLE SHOOTING INSTRUCTIONS 24

7TECHNICAL DATA 25

7.1 Dimensioned Sketch DA 50-650 (in mm) ........................................................25

7.2 Tensile Force....................................................................................................26

7.3 Air Output .........................................................................................................26