Page 11

Spectra Series AUT1B Operator• REV2

• Excessive wear, gouges, damaged handles,

missing covers, and other physical problems

• Drifting out of position

• Dicultyduringroutinepositioningrequiring

excessive push/pull force

• Missing or loose screws and fasteners

• Electrical burns

• Evidence of high temperature traces

indicating a possible concentration of heat

• Accumulation of lint

• Evidenceofingressofuid

4-5. Routine Inspections

• Check all attaching hardware (e.g., screws,

nuts, bolts) for tightness. Any missing hardware

MUST be replaced.

• Inspect Main Power ON/OFF Switch

operation and Intensity ON/OFF button

operation.

• Articulate the Balance Mechanism and

rotate each articulation point while observing

for lighthead function and the ability of the arm

to remain in any position throughout the entire

range of movement.

• Inspectpolycarbonatediuserfordamageor

scratches.

• Clean and disinfect according to cleaning

instructions.

4-6. Preventive Maintenance

This device requires periodic inspection

administered by a SKYTRON authorized service

representative. There are no user serviceable

componentsinsidetheAUT1Blightxture.Service

oftheAUT1Blightxturemustbeperformedby

SKYTRON authorized service technicians using

SKYTRON authorized replacement parts and

service techniques.

CAUTION

Prior to replacing the fuse, make sure

the facility circuit breaker for the boom

mountedlightisturnedo.Replacethe

fuse with 1Amp timelag only.

SKYTRON Service Manuals are available

upon request; however, non-authorized service

personnel are required to complete applicable

service training. For a syllabus, schedule,

availability, cost and overview; logon to

www.skytron.us and click on TRAINING. If

interested in attending a training session, contact

your SKYTRON representative for sponsorship.

To obtain SKYTRON authorized service or

preventive maintenance contracts, contact your

nearest SKYTRON representative.

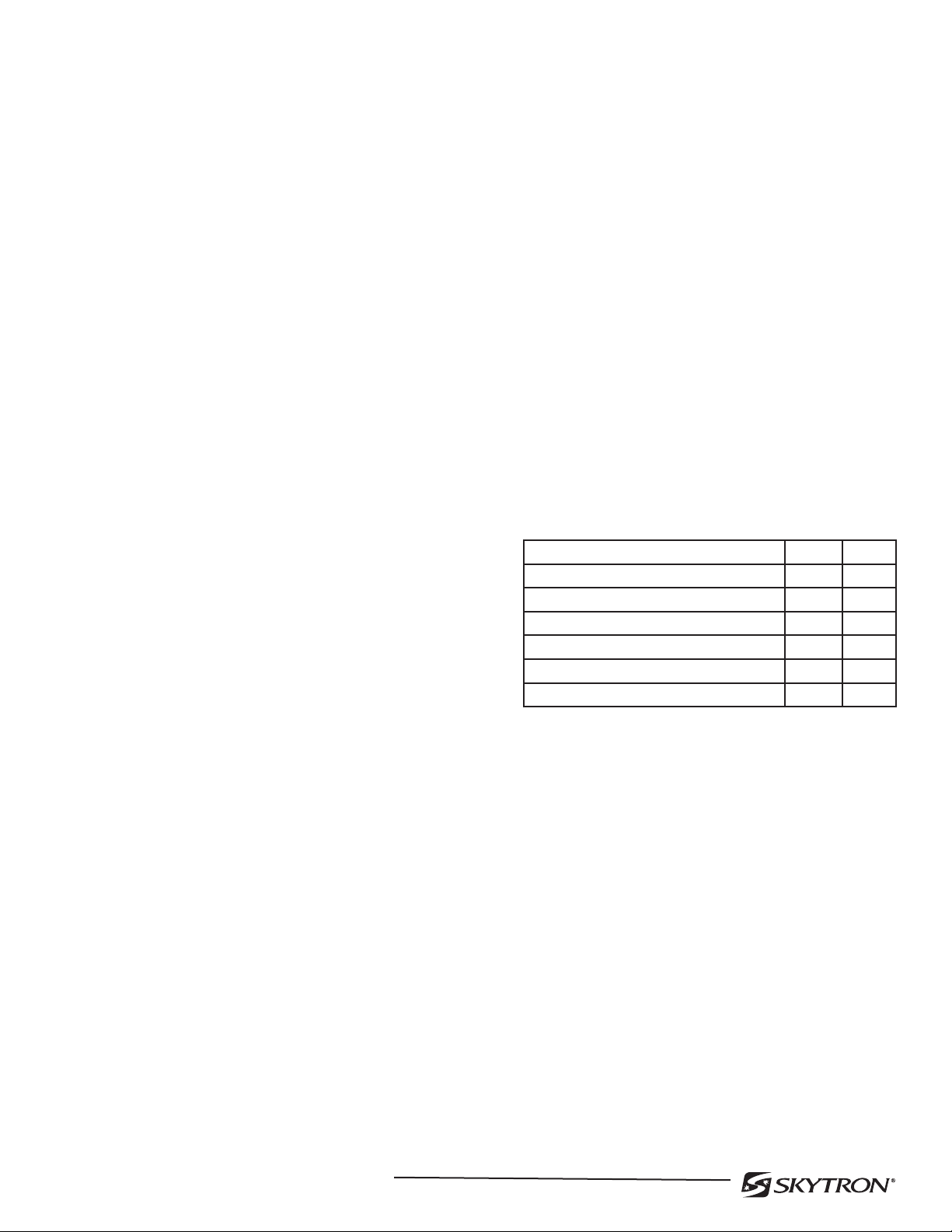

ThespecicitemsintheMAINTENANCEMATRIX

must be inspected and repaired as necessary.

The suggested time intervals are intended as a

guideline only and actual maintenance will vary

by use and conditions. For optimal usage, safety,

and longevity of the product, have it serviced only

by a SKYTRON authorized service representative

using SKYTRON authorized replacement parts and

service techniques.

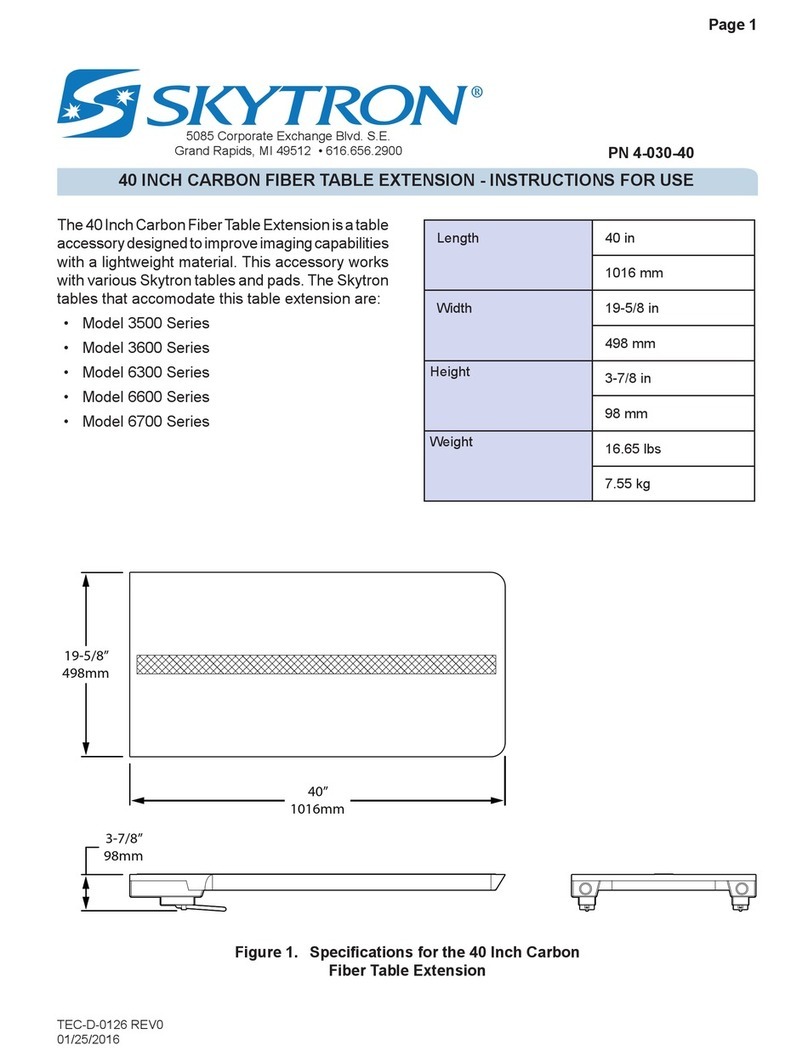

MAINTENANCE MATRIX

Component 6 Mo. 1 Yr.

Mounting Hardware (Tighten) X

Inspect Electrical Connections X

Covers & Attachment Hardware X

Overall Aesthetic Condition X

Product Caution & Warning Labels X

Fixture Ground Test X

Degradation of LED life begins from the date of

rstuse.However,theneedforLEDreplacement

should not be experienced until the LED usage has

reached 40,000 hours (with the average intensity

at it's highest setting).

Based on an 8 hour daily usage the expected

operating life of the LED’s will be approximately

13.5 years. Light usage will vary depending on

facility and amount of daily use. Continued use

of the examination luminaire after the expected

operating life expectancy will result in diminished

illuminancevalues,reducingintensity,andaecting

color temperature. If diminished light output is

noticed with the light please contact your Skytron

representative immediately.