EQY#-TF222-152EN

Page 1 of 3

Instruction Manual

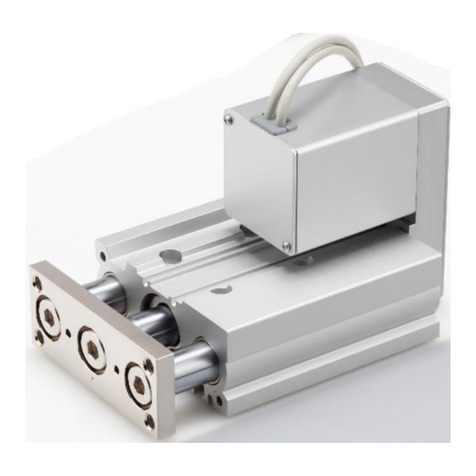

e-Actuator

/

Rod type

Easy to operate Integrated Controller

Series EQY*H*-****-B*

Motor: Step motor 24 VDC with Battery-less absolute encoder

The intended use of this Electrical Actuator is to convert an electrical

input signal into mechanical motion.

1. Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC) *1), and other safety regulations. *1)

ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Manipulating industrial robots -Safety. Etc.

Refer to the product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Warning

•Always ensure compliance with relevant safety laws and standards.

All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

•Electromagnetic compatibility

This product is class A equipment intended for use in an industrial

environment. There may be potential difficulties in ensuring

electromagnetic compatibility in other environments due to conducted

as well as radiated disturbances.

2. Specifications

2.1 EQY25 series

Pushing Force [N] *2) *3) *4)

Max. acceleration/

deceleration [mm/s2]

Pushing speed

[mm/s

2

]

*5)

Positioning repeatability [mm]

Impact/Vibration resistance [m/s

2

]

*7)

Ball screw (EQY*DH)

Ball screw + Belt (EQY*H)

Sliding bush (piston rod)

Operating temperature [°C]

Operating humidity [% RH]

90 or less (no condensation)

Battery-less absolute

(Step motor 24 VDC)

Encoder

(angular displacement sensor)

Power consumption [W] *9)

Pushing Force [N] *2) *3) *4)

Max. acceleration/

deceleration [mm/s2]

Pushing speed

[mm/s

2

]

*5)

Positioning repeatability [mm]

Impact/Vibration resistance [m/s

2

]

*7)

Ball screw (EQY*DH)

Ball screw + Belt (EQY*H)

Sliding bush (piston rod)

Operating temperature [°C]

Operating humidity [% RH]

90 or less (no condensation)

Battery-less absolute

(Step motor 24 VDC)

Encoder

(angular displacement sensor)

Power consumption [W] *9)

2. Specifications (continued)

*1)Horizontal:Use an external guide (external guide friction coefficient: 0.1 or less).

The maximum value of the work load for the positioning operation.

The actual transported mass and transport speed will vary depending on the

external guide conditions.

Vertical:Use an external guide (external guide friction coefficient: 0.1 or less)

when the rod is directed upward or radial load is applied to the rod.

This is the maximum value of the work load for the positioning operation.

The actual transported mass and transport speed will vary depending on the

external guide conditions.

Check the speed/acceleration and duty ratio depending on the payload in the

"Speed vs. payload graph" in the catalogue.

Set the acceleration/deceleration to horizontal: 10,000 [mm/s2] or less, vertical:

5000 [mm/s2] or less.

*2)Pushing force accuracy is ±20% (F.S.).

*3)The setting range for the "Pushing force" is from 25% to 50% (EQY25*H) and

30% to 70% (EQY32*H).

The pushing force setting range varies depending on the duty ratio and pushing

speed. Check the "Thrust Conversion Graph" in the catalogue.

*4)Speed and thrust may vary depending on the cable length, load, installation

conditions, etc.

If the cable length exceeds 5 m, the speed/thrust will decrease by up to 10% for

every 5 m. (for 15 m: max. 20% reduction)

*5)"Pushing speed” is the allowable speed for the pushing operation.

When transporting and pushing a workpiece, operate the actuator according to

the "vertical load capacity" or less.

*6)This is a reference value for correcting errors in reciprocating motion.

*7)Impact resistance: In a drop impact test, no malfunction occurred in the axial

direction and perpendicular direction of the feed screw (at the initial state).

Vibration resistance: 45 to 2000 Hz, 1 sweep, no malfunction in the axial

direction and perpendicular direction of the feed screw (at the initial state).

*8)Power indicates the maximum power during operation including the controller.

Use this when selecting the power supply capacity.

*9)For an actuator with lock, add the power consumption for the lock.

*10)Only applies to actuators supplied with a lock.

2.3 Weight [kg]

EQY25 (with In-line motor)

EQY25 (with Parallel motor)

EQY32 (with In-line motor)

EQY32 (with Parallel motor)

Warning

For special products which include a suffix of “-X#”, “-D#”, please refer to

the customer drawing of that specific product.

3. Installation

3.1 Installation Warning

•Do not install the product unless the safety instructions have been read

and understood.

•Do not use the product outside of its allowable specification.

•Ensure the product is sized correctly and is suitable for the application.

•Do not operate the product by fixing the piston rod and moving the

actuator body.

•Keep the flatness of the mounting surface to within 0.1 mm max.

Insufficient flatness of a work piece or actuator mounting surface can

cause play in the guide and increased sliding resistance. In the case

of overhang mounting (including cantilever), use a support plate or

support guide to avoid deflection of the actuator body.

3. Installation (continued)

•When mounting the actuator, use all mounting holes.

If all mounting holes are not used, this will not maintain the specified

performance. e.g. the amount of displacement of thetable will increase.

•When mounting the actuator or workpiece, use screws with adequate

length, but with length less than the maximum thread depth. The use

of screws that are too long can touch the body and cause malfunction.

•Tightening the screws with a torque higher than recommended may

cause malfunction, whilst tightening with a torque lower than

recommended can cause displacement of the mounting position, or

dropping of the work piece.

•Avoid using the electric actuator in a way that rotational torque would

be applied to the piston rod. If rotational torque is applied to the piston

rod it will cause deformation, damage and/or reduce the non-rotational

accuracy of the product. The allowable rotational torque is listed below.

Allowable Rotational torque

(N·m or less)

•When screwing a bracket or nut onto the threaded portion at the tip of

the piston rod, make sure to retract the piston rod fully, and place a

wrench over the flat portion of the rod that protrudes.

Tighten with consideration to prevent the tightening torque from being

applied to the non-rotating guide.

3.2 Environment Warning

•Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

•Do not use in an explosive atmosphere.

•Do not expose to direct sunlight. Use a suitable protective cover.

•Do not install in a location subject to vibration or impact in excess of

the product’s specifications.

•Do not mount in a location exposed to radiant heat that would result in

temperatures in excess of the product’s specifications.

•Avoid use in the following environments:

1. Locations where a large amount of dust and cutting chips are

airborne.

2. Locations where the ambient temperature is outside the range of

the temperature specification (refer to specifications).

3. Locations where the ambient humidity is outside the range of the

humidity specification (refer to specifications).

4. Locations where strong magnetic or electric fields are generated.

5. Locations where direct vibration or impact is applied to theproduct.

6. Areas that are dusty, or are exposed to splashes of water and oil

drops.

7. Environments at an altitude of 1000 meters or higher. Heat

dissipation and withstand voltage will decrease. Contact SMC for

details.

•Do not use in an environment where the product is directly exposed to

liquid, such as cutting oils.

•Install a protective cover when the product is used in an environment

directly exposed to foreign matter such as dust, cutting chips and

spatter.

3.3 Lubrication Caution

•The product has been lubricated for life at manufacture and does not

require lubrication in service. If a lubricant is to be used, contact SMC.