Installation and Maintenance Manual

Series ITV20*0-X155, ITV30*0-X37

(DeviceNet Compatible Type).

Electro-Pneumatic Regulator

For future reference, please keep this manual in a safe place

This manual should be read in conjunction with the current catalogue

From SMC Japan Document No. ITV2-0M00034

These safety instructions are intended to prevent a hazardous

situation and / or equipment damage. These instructions indicate

the level of potential hazard by label of “Caution” “Warning”, or

“Danger”. To ensure safety, be sure to observe ISO 4414 (Note 1), JIS

B 8370 (Note 2) and other safety practices.

(Note1): ISO 4414: Pneumatic fluid power-Recommendations for

the application of equipment to transmission and control systems.

(Note 2): JIS B 8370: Pneumatic system axiom

CAUTION

: Operator error could result in injury or equip-

ment damage.

WARNING

: Operator error could result in serious injury

or loss of life.

DANGER

: In extreme conditions, there is a possible result

of serious injury or loss of life.

1. The compatibility of pneumatic equipment is the

responsibility of the person who designs the

pneumatic system or decides its specifications.

Since the products specified here are used in various

operating conditions, their compatibility for the specific

pneumatic system must be based on specifications or after

analysis and/or tests to meet your specific requirements.

2. Only trained personnel should operate

pneumatically operated machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar

with it. Assembly, handling or repair of pneumatic systems

should be performed by trained and experienced operators.

3. Do not service machinery / equipment or attempt to

remove component until safety is confirmed.

1) Inspection and maintenance of machinery / equipment

should only be performed after confirmation of safe

locked-out control positions.

2) When equipment is to be removed, confirm the safety

process as mentioned above. Switch off air and electrical

supplies and exhaust all residual compressed air in the

system.

3) Before machinery / equipment is re-started, ensure all

safety measures to prevent sudden movement of

cylinders etc. (Supply air into the system gradually to

create back-pressure, i.e. incorporate a soft-start valve.)

4. Contact SMC if the product is to be used in any of

the following conditions:

1) Conditions and environments beyond the given

specifications, or if product is used outdoors.

2) Installation on equipment in conjunction with atomic

energy, railway, air navigation, vehicles, medical

equipment, food and beverage, recreation equipment,

emergency stop circuits, press applications, or safety

equipment.

3) An application which has the possibility of having

negative effects on people, property, or animals requiring

special safety analysis.

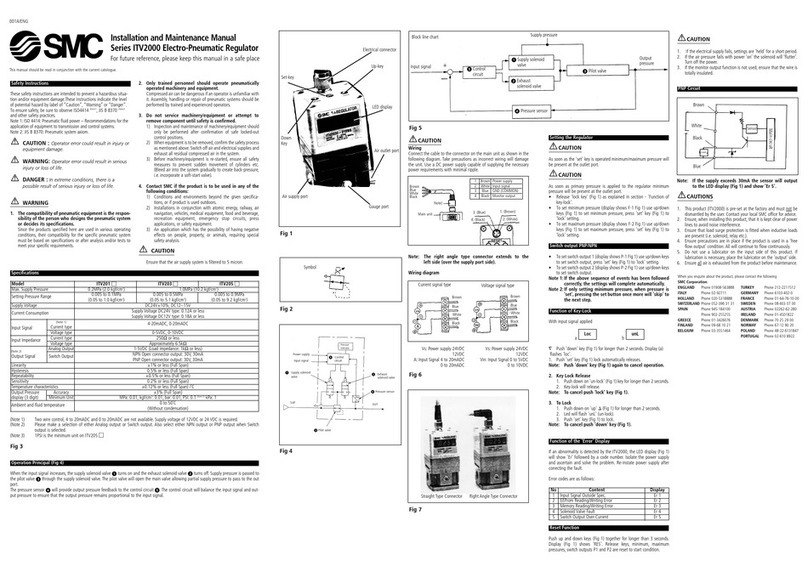

Ensure that the air supply system is filtered to 5 micron

(Note 1) Excludes current consumption of DeviceNet communication line.

(Note 2) Select Set pressure with 4096 resolution, corresponding to the maximum setting pressure of 100%

(Note 3) Select monitor pressure with 4096 resolution, corresponding to the maximum output pressure of 100%

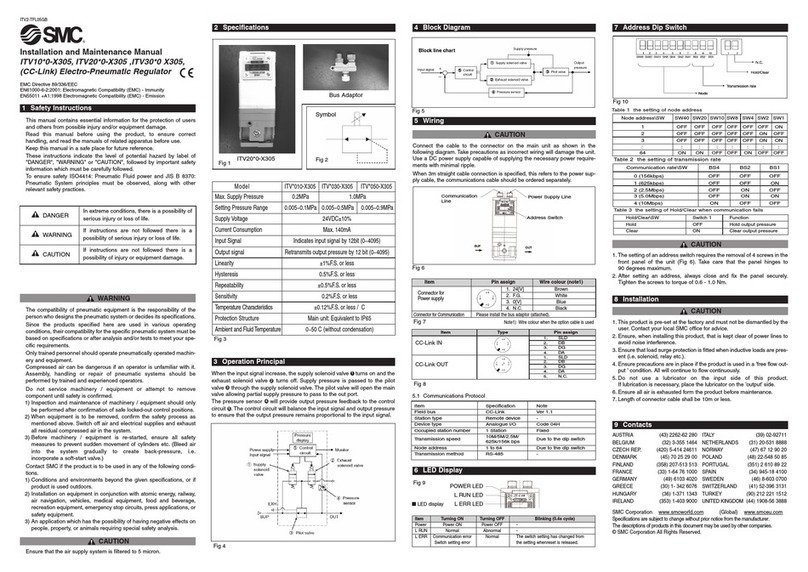

Fig 3

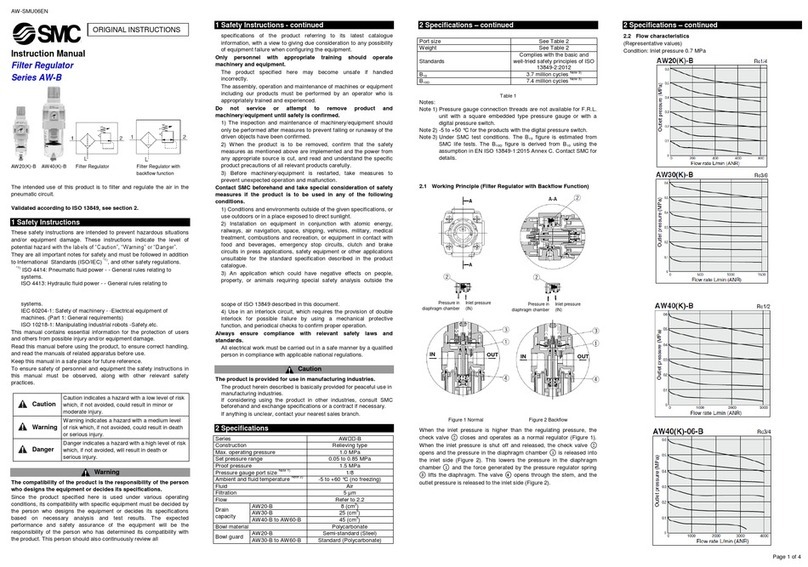

When the input signal increases, the supply solenoid valve turns on and the exhaust solenoid valve turns off. Supply pressure is

passed to the pilot valve through the supply solenoid valve. The pilot valve will open the main valve allowing partial supply pressure to

pass to the out port.

The pressure sensor will provide output pressure feedback to the control circuit . The control circuit will balance the input signal and

output pressure to ensure that the output pressure remains proportional to the input signal.

Safety Instructions

WARNING

CAUTION

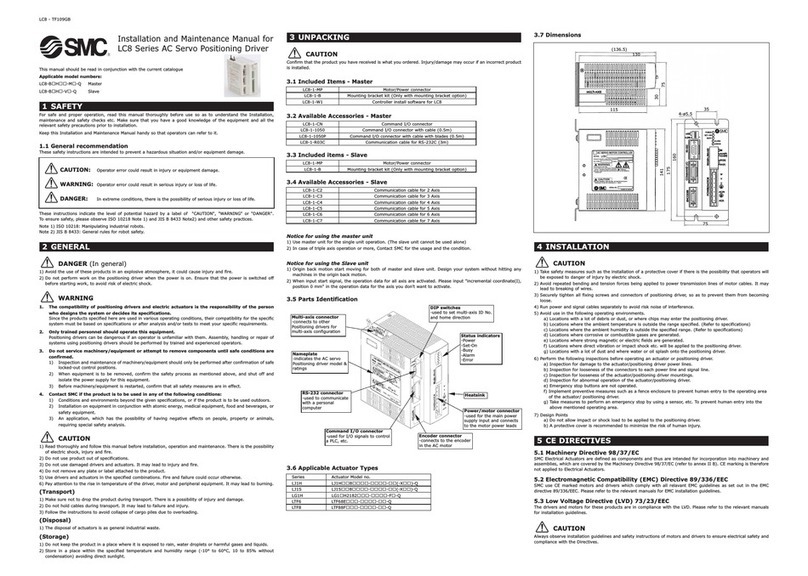

Specifications

Model ITV2010-X155 ITV2030 - X155 ITV2050-X155

ITV3010-X37 ITV3030 - X37 ITV3050-X37

Min.Supply Pressure Setting Pressure + 0.1 MPa

Max.Supply Pressure 0.2 MPa (2.0 kgf/cm2) 1.0 MPa (10.2 kgf/cm2)

Setting Pressure Range 0.005-0.1MPa 0.005-0.5MPa 0.005-0.9MPa

Max. Flow Rate 1500 l/ min (ANR) ITV20** (SUP: at 0.7 MPa)

5000 l/ min (ANR) ITV30** (SUP: at 0.7 MPa)

Supply Voltage 24 VDC 10%

Current Consumption Max. 012A Note 1

Input Signal Indicates Input Signal by 12 bit Note 2

Output Signal Retransmits Output Pressure by 12 bit Note 3

Linearity 1% or less (Full Scale)

Hysteresis 0.5% or less (Full Scale)

Repeatability 0.5% or less (Full Scale)

Sensitivity 0.2% or less (Full Scale)

Temperature Characteristics 0.12% or less (Full Scale) /

Protection Structure Main unit: IP65, Cable connector: IP67

Ambient and fluid temperature 0-50 (without condensation)

±

±

±

±°C

°C

Operation Principle

Fig 1

Fig 2

Fig 4

Symbol

Power supply

Input signal

Pilot valve

Supply

solenoid valve

SUP

EXH

Control

circuit

Pressure

indicator

Exhaust

solenoid valve

Pilot EXH

Pressure

sensor

OUT

Fig 5

Connect the cables to the connectors on the unit as shown in the

following diagrams. Take precautions as incorrect wiring will

damage the unit. Use a DC power supply capable of supplying the

necessary power requirements with minimal ripple.

When 3m straight cable connection is specified, this refers to the

power supply cable, the communications cable should be ordered

separately.

Fig 6

Fig 7

Fig 8

Fig 9

Fig 10

Note: Dip switch 9 is selected to temporarily hold or clear the

output pressure, in the event that either of the following

occur

1. When the DeviceNet line causes a communication error due

to disconnection.

Block line chart

Pressure sensor

Exhaust solenoid

valve

Pilot valve

Output

pressure

Control

circuit

Input signal

Supply solenoid

valve

Supply pressure

CAUTION

Wiring

PowerSupplyLine

Address Switch

SUP OUT

Communication

Line

Brown

White

Blue

Black

Supply Voltage

No Connect

GND

No Connect

Brown

White

Blue

Black

DeviceNet connections

No. Code Color Function

1 Drain Naked Device shield for signal line

2 V+ Red Power supply (+) to communication satation

3 V- Black Power supply (-) to communication satation

4 CAN-H White Device Net signal

5CAN-L Blue DeviceNetsignal

Protocol DeviceNet Ver 2.0

Comm Speed 125 k, 250 k, 500 k BPS

Slave type Group 2 only

Device type 00h (Generic Device)

Connections

supported Explicit, Polled I/O

Protocol

LED Display

PowerLED

MOD/NET LED (Combined Module/Network Status)

OFF Power OFF (interface unit)

GREEN Power ON (interface unit)

OFF The unit is not on-line

FLASHING GREEN The unit is on-line but not allocated

SOLID GREEN The unit is on-line and allocated to a master

FLASHING RED Recoverable fault, the I/o connection has timed out

SOLID RED Unrecoverable fault, can not recover

POWER LED MOD/NET LED

Address Dip Switch

Node address (6 bit) + Data rate (2 bit)

Date rate

Setting method

0-Dominated by switch, cannot

overwrite with software (HW

setting)

1-Dominated by software,

Switches from 1 to 8 have no

function (SW setting)

Note:

For the communication error

0- Clear output pressure

1- Hold output pressure

2. When the power supply to the ITV is switched off or

disconnected whilst unit is communicating.

The condition of the output pressure during recovery of either

connection depends on the position of the dip switch.

0 Output pressure is Cleared

1 Output pressure is Held

1. The setting of an address switch requires the removal of 4

screws in the front panel of the unit (Fig 6). Take care that the

panel hinges to 90 degrees maximum.

2. After setting an address, always close and fix the panel

securely. Tighten the screws to a torque of 0.6 – 1.0 Nm.

1. If the air pressure fails with power ‘on’ the solenoid will

‘flutter’. Turn off the power to stop the pressure supply or

make an input signal of 0%

1. This product is pre-set at the factory and must not be

dismantled by the user. Contact your local SMC office for

advice.

2. Ensure, when installing this product, that it is kept clear of

power lines to avoid noise interference.

3. Ensure that load surge protection is fitted when inductive

loads are present (i.e. solenoid, relay etc.).

4. Ensure precautions are in place if the product is used in a

‘free flow output’ condition. All will continue to flow

continuously.

5. Do not use a lubricator on the input side of this product. If

lubrication is necessary, place the lubricator on the ‘output’

side.

6. Ensure all air is exhausted form the product before

maintenance.

When you enquire about the product, please contact the following

SMC Corporation:

Phone Phone

AUSTRIA (43) 2262-62 280 ITALY (39) 02-92711

BELGIUM (32) 3-355 1464 NETHER-

LANDS

(31) 20-531 8888

CZECH REP. (420) 5-414 24611 NORWAY (47) 67 12 90 20

DENMARK (45) 70 25 29 00 POLAND (48) 22-548 50 85

FINLAND (358) 9-859 580 PORTUGAL (351) 2-610 89 22

FRANCE (33) 1-64 76 1000 SPAIN (34) 945-18 4100

GERMANY (49) 6103 4020 SWEDEN (46) 8-603 0700

GREECE (30) 1-342 6076 SWITZERLAND (41) 52- 396 3131

HUNGARY (36) 1-371 1343 TURKEY (90) 212 221 1512

IRELAND (353) 1-403 9000 UK (44) 1908-56 3888

CAUTION

CAUTION

CAUTION

ITV2-TFI21GB