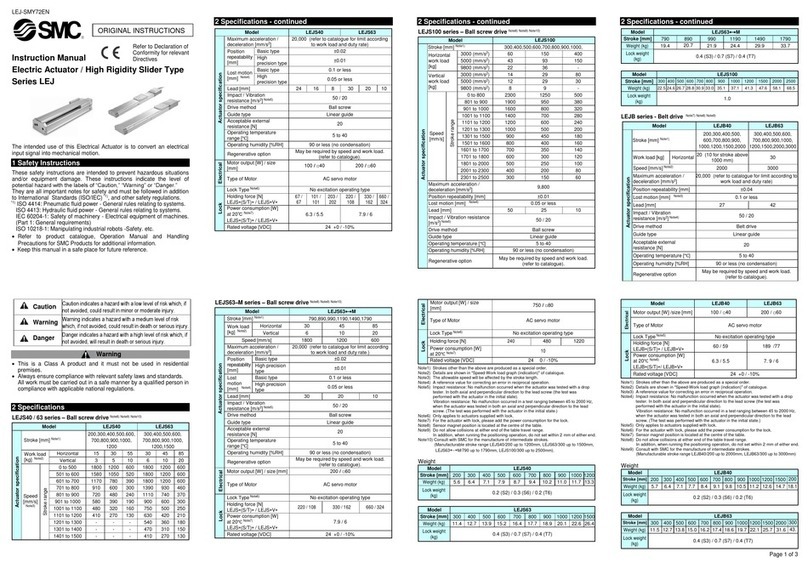

Front matter 3

Series MY3

Types of Moment Applied to Rodless Cylinders

Multiple moments may be generated depending on the mounting orientation, load and position of the center of gravity.

Calculation of Guide Load Factor

1.

Maximum load weight (1), static moment (2), and dynamic moment (3) (at the time of impact with stopper) must be examined for the selection calculations.

∗To evaluate, use υa (average speed) for (1) and (2), and υ(impact speed υ= 1.4υa) for (3). Calculate m max for (2) from the maximum allowable load graph (m1, m2, m3 )

and Mmax for (2) and (3) from the maximum allowable moment graph (M1, M2, M3).

2. Reference formulas [Dynamic moment at impact]

Use the following formulas to calculate dynamic moment when taking stopper impact into consideration.

m:Load weight (kg)

F:Load (N)

FE:

Load equivalent to impact (at impact with stopper) (N)

υa: Average speed (mm/s)

M:Static moment (N •m)

υ= 1.4υa (mm/s) FE= 1.4υa x δx m •g

1

ME=

—

•FE•L1= 4.57υaδm L1 (N •m)

3

Note 4) 1.4υaδ is a dimension less coefficient for calculating impact force.

Note 5) Average load coefficient = :

This coefficient is for averaging the maximum load moment at the time of stopper impact according to service life calculations.

3. For detailed selection procedure, please refer to pages 2, 3, 18, 19.

Coordinates and Moments

z

y

M3: Yawing

xM2: Rolling

M1: Pitching

Horizontal

mounting

Wall

mounting

Ceiling

mounting

m3x g

x

M2

z

M3

X

Z

y

m1x g

M1

X

x

M2

Yy

m2x g

M1

X

x

M2

Y

Vertical

mounting

g: Gravitational acceleration

M1

Z

M3

zy

Y

Note)

m

4

is a mass movable by thrust. Use 0.3 to 0.7 times the thrust

(differs depending on the operating speed) as a guide for actual use.

Mounting direction

Static load m

Horizontal

m1

Ceiling

m2

Wall

m3

M1

M2

M3

m1x gx X

m1x gx Y

—

m2x gx X

m2x gx Y

—

—

m3x gx Z

m3x gx X

m4x gx Z

—

m4x gx Y

Vertical

m4

M1

FE

M3

Y

υa

Mounting direction

Dynamic load

FE

Horizontal Ceiling Wall Vertical

Note) Regardless of the mounting orientation, dynamic moment is

calculated with the formulae above.

Dynamic moment M2E will not be generated.

1.4υax δx mnx g

x FEx Z

1

3

x FEx Y

1

3

M1E

M2E

M3E

Load Weight and Static Moment

g: Gravitational acceleration

υa: Average speed

δ: Bumper coefficient

Note 1) Moment caused by the load, etc., with cylinder in resting condition.

Note 2) Moment caused by the impact load equivalent at the stroke end (at the time of impact with stopper).

Note 3) Depending on the shape of the work piece, multiple moments may occur. When this happens, the sum of the load factors (Σα) is the total of all such moments.

FE

ME

m

L

1

υ

Z

FE

M1E

υa

M3E

Dynamic Moment

mnx g

mnx g

m4x g

Static

moment

Dynamic

moment

Note)

Σα=+ + <1

=

Load weight

[

m

]

Maximum load weight

[

m max

]

Static moment

[

M

]

Allowable static moment

[

Mmax

]

Sum of guide

load factors

Note 1) Dynamic moment [M

E

]

Allowable dynamic moment

[

M

E

max

]

Note 2)

Note 5)

Note 4)

1

3

•

••

υ: Impact speed (mm/s)

L1: Distance to the load’s center of gravity (m)

ME: Dynamic moment (N •m)

δ: Bumper coefficient

With rubber bumper = 4/100

With air cushion = 1/100

With shock absorber = 1/100

g:Gravitational acceleration (9.8 m/s2)

()

MY3A3B.qxd 06.2.17 9:13 AM Page 6