- 1 -

Contents

1. Safety Instructions.......................................................................... 5

2.Product Outline............................................................................... 7

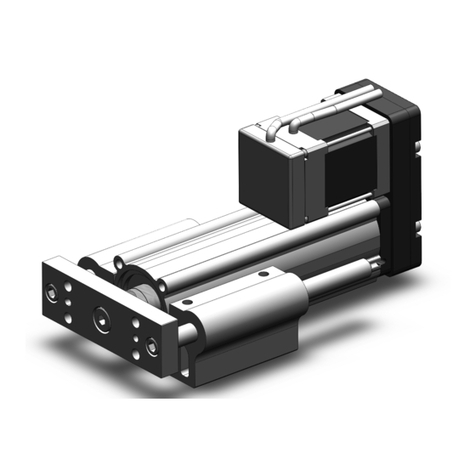

2.1 Product features ...........................................................................................................................................7

2.2 Product configuration................................................................................................................................8

2.3 How to Order...................................................................................................................................................9

2.4 Option.............................................................................................................................................................. 10

(1)Actuator cable (5m or less).............................................................................................................. 10

(2) Actuator cable (8-20m)...................................................................................................................... 10

(3) Actuator cable for with lock and sensor (5m or less)...................................................... 11

(4) Actuator cable for with lock and sensor (8-20m)................................................................ 11

(5) Communication plug connector.................................................................................................. 12

(6) Controller setting kit........................................................................................................................... 12

(7) Teaching box.......................................................................................................................................... 13

2.5 Startup Procedures.................................................................................................................................. 14

(1) Confirmation of the package content........................................................................................ 14

(2) Installation............................................................................................................................................... 14

(3) Controller setting................................................................................................................................. 14

(4) PLC Setting.............................................................................................................................................. 14

(5) Wiring and connection...................................................................................................................... 14

(6) Power ON alarm (error)..................................................................................................................... 15

(7) Parameter setting................................................................................................................................. 15

(8) Operation pattern setting................................................................................................................. 16

(9) Trial run ..................................................................................................................................................... 16

3. Product Specifications ................................................................. 17

3.1 Specifications.............................................................................................................................................. 17

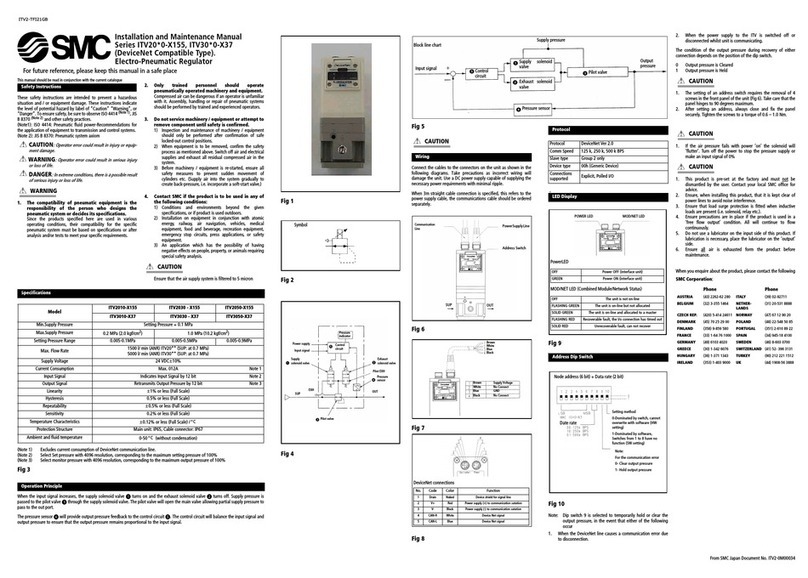

(1) Basic specifications........................................................................................................................... 17

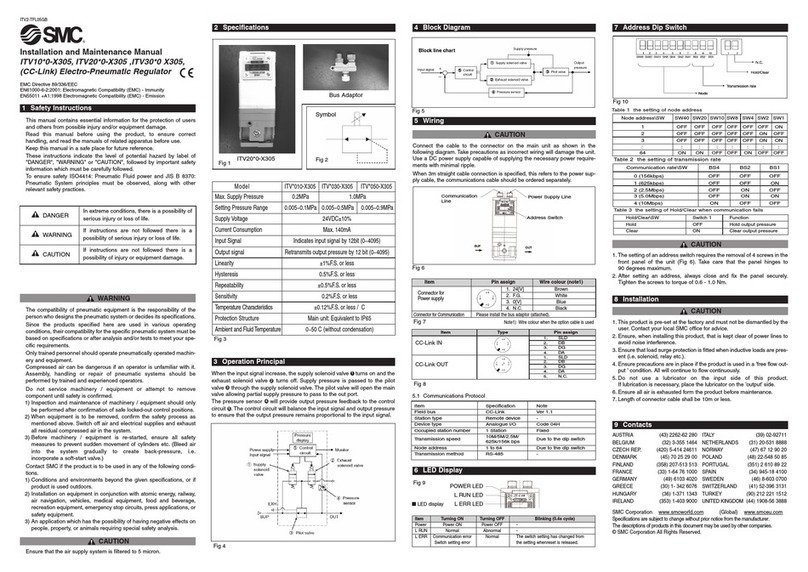

(2)CC-Link type ............................................................................................................................................ 18

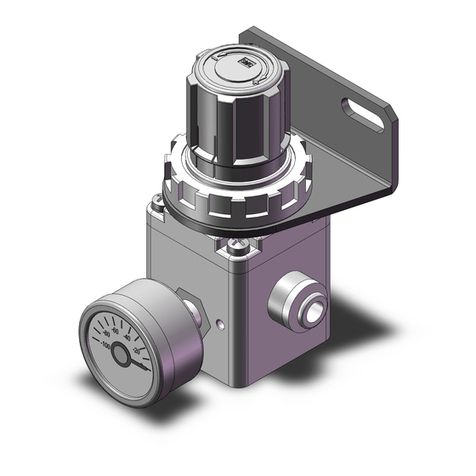

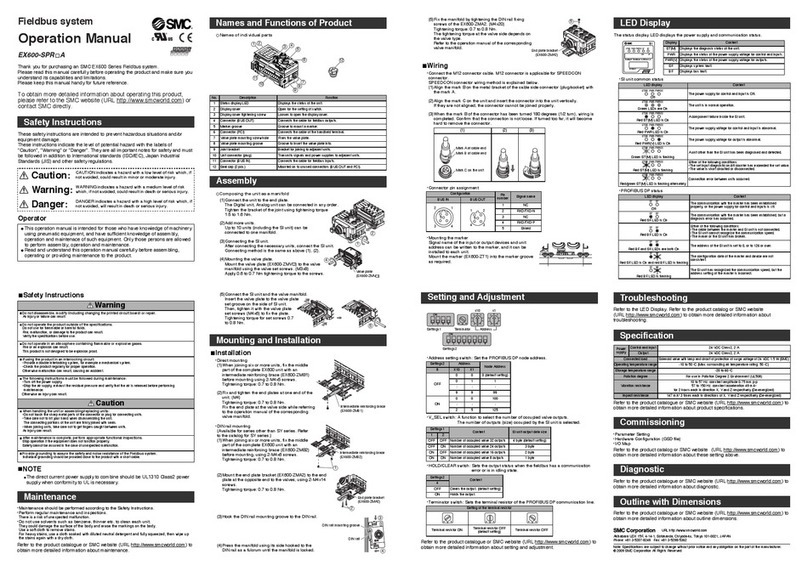

3.2 Parts description....................................................................................................................................... 19

3.3 Outside dimension diagram................................................................................................................ 20

(1) Screw mount type (LECPMJ□-□)............................................................................................ 20

(2) DIN rail mount type (LECPMJ□D-□) ....................................................................................... 20

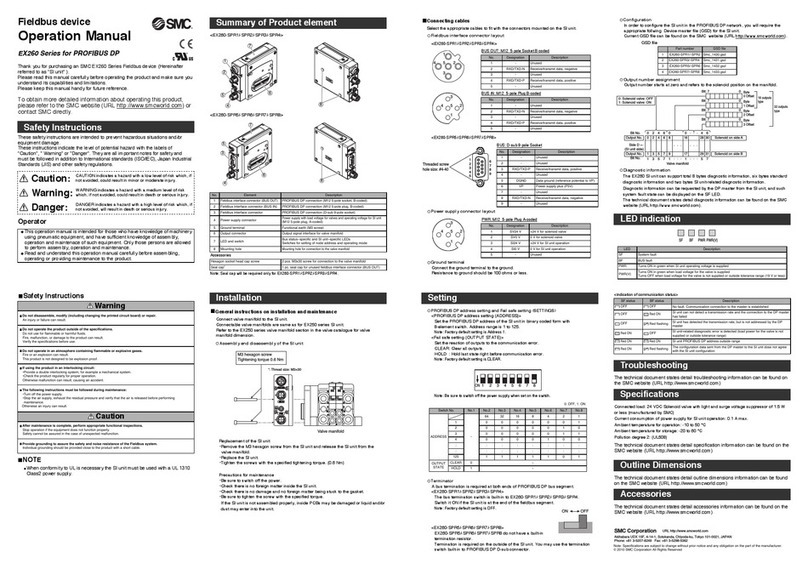

3.4 How to install............................................................................................................................................... 21

(1) How to install.......................................................................................................................................... 21

(2) Ground wire connection................................................................................................................... 21

(3) Installation location............................................................................................................................ 22

4. Initial Setting ................................................................................. 23