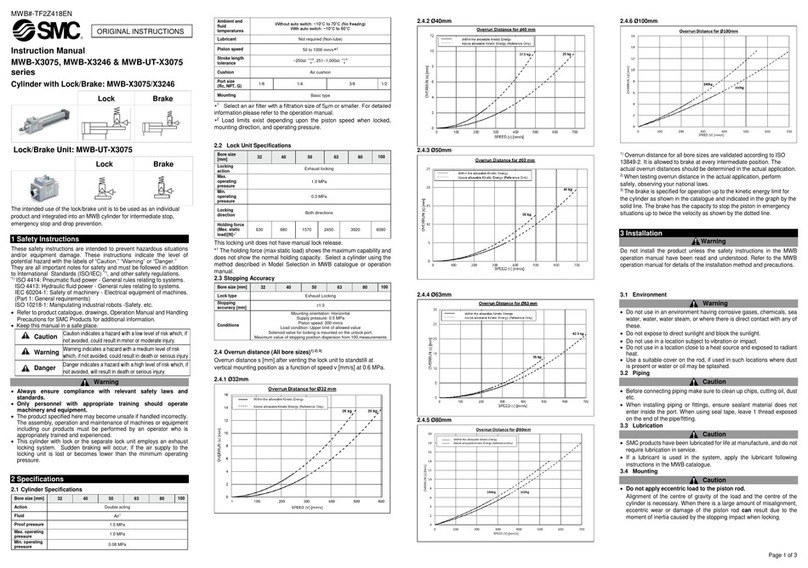

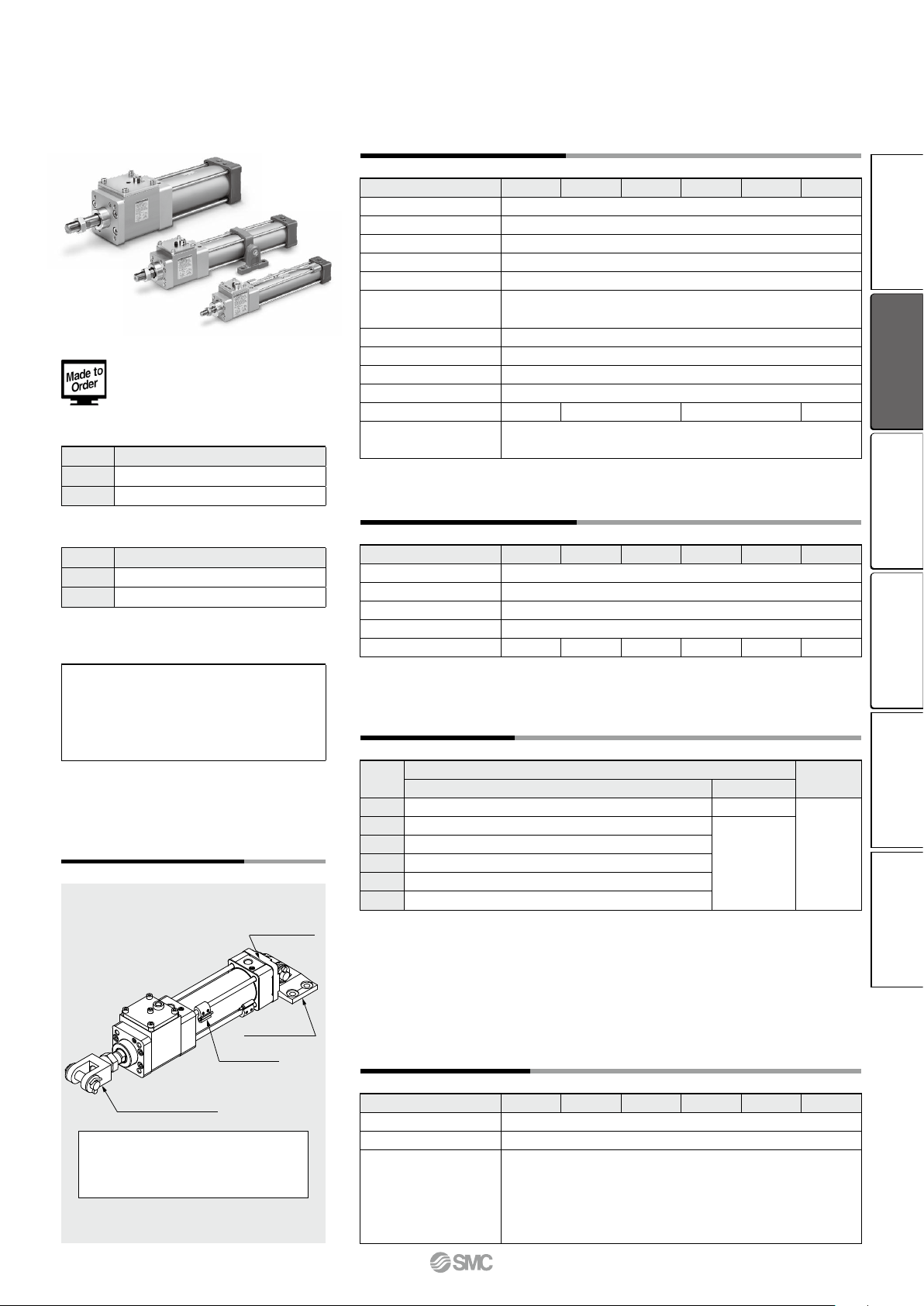

Cylinder with Lock

Double Acting, Single Rod MWB Series

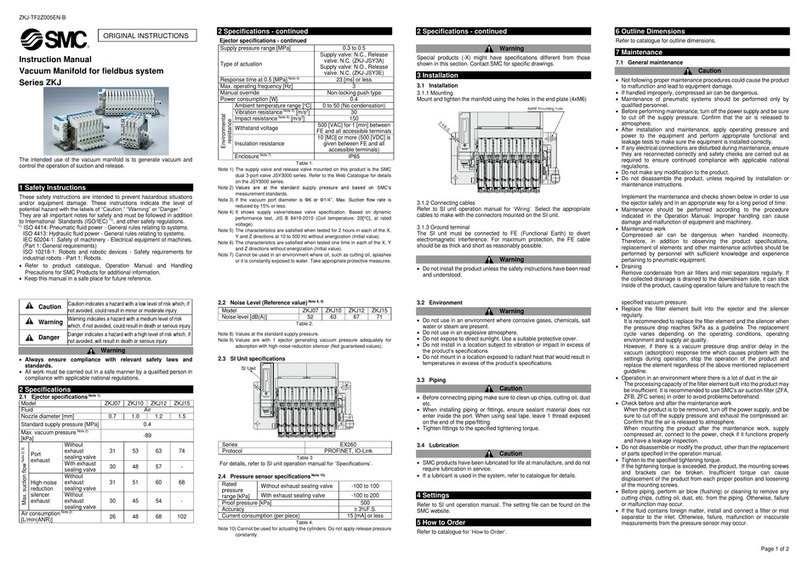

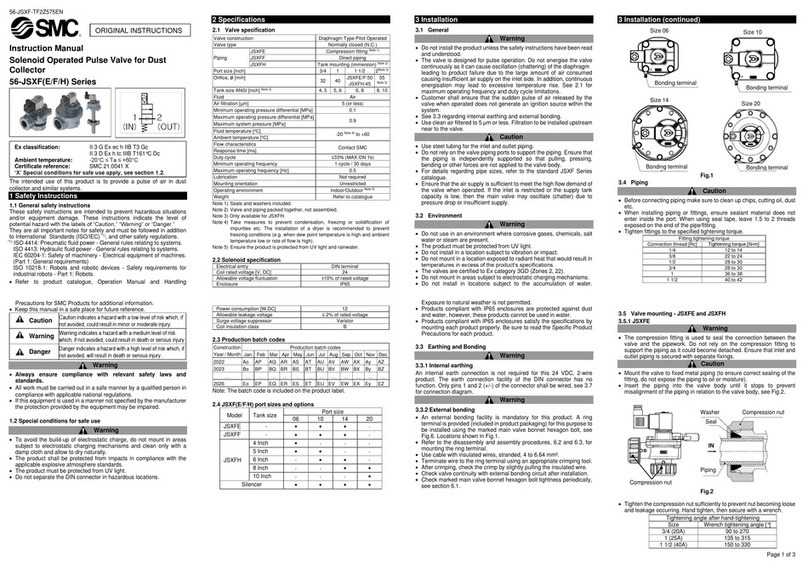

Lock Unit Specifications

*1

The holding force (max. static load) shows the maximum capability and does not show the normal

holding capability. Be sure to select a cylinder using the method described in Model Selection (page 5).

Bore size [mm] 32 40 50 63 80 100

Locking action Exhaust locking

Max. operating pressure

1.0 MPa

Min. operating pressure

0.3 MPa

Locking direction Both directions

Holding force (Max. static load) [N]

*1630 980 1570 2450 3920 6080

For details of cylinders with auto switches

e pages 24 to 30

·

Auto Switch Proper Mounting Position (Detection

at stroke end) and Mounting Height

· Minimum Stroke for Auto Switch Mounting

· Auto Switch Mounting Brackets/Part Nos.

· Operating Range

Ordering Example of

Cylinder Assembly

Cylinder model: MDWBD32-50-NW-M9BW

*

Pivot bracket, double knuckle joint, and auto switch are

shipped together with the product, but not assembled.

Mounting D: Double clevis

Pivot bracket N: Yes

Rod end bracket W: Double knuckle joint

Auto switch D-M9BW: 2 pcs.

Cylinder Specifications

*1

Load limits exist depending upon the piston speed when locked, mounting direction, and operating pressure.

Bore size [mm] 32 40 50 63 80 100

Action Double acting, Single rod

Fluid Air

Proof pressure 1.5 MPa

Max. operating pressure

1.0 MPa

Min. operating pressure

0.08 MPa

Ambient and fluid

temperatures

Without auto switch: −10°C to 70°C

With auto switch: −10°C to 60°C (No freezing)

Lubricant Not required (Non-lube)

Piston speed 50 to 1000 mm/s*1

Stroke length tolerance

Up to 250 st:

+1.0

0

, 251 to 1000 st:

+1.4

0

, 1001 to 1500 st:

+1.8

0

, 1501 to 2000 st:

+2.2

0

Cushion Air cushion or Rubber bumper

Port size (Rc, NPT, G) 1/8 1/4 3/8 1/2

Mounting Basic, Axial foot, Rod flange, Head flange

Single clevis, Double clevis, Center trunnion

Auto switch

Pivot bracket

Standard Strokes *When using with auto switches, refer to the Minimum Stroke for

Auto Switch Mounting table on pages 26 to 28.

Bore

size

Standard stroke

Max.

manufacturable

stroke

Stroke range q

Stroke range

w

32

25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500

Up to 1000

Up to 2500

40

25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500

Up to 1800

50

25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500, 600

63

25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500, 600

80

25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500, 600, 700, 800

100

25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500, 600, 700, 800

*The manufacturing of intermediate strokes is possible. (Spacers are not used.)

*

Applicable strokes should be confirmed according to the usage. For details, refer to the Air Cylinders

Model Selection in the Web Catalog. In addition, products that exceed the stroke range qmight

not be able to fulfill the specifications due to deflection, etc.

*Please consult with SMC for details on manufacturability and for part numbers when exceeding

the stroke range w.

*When using a rod boot, a stroke range of up to 1000 mm is available. Please consult with SMC

when exceeding a 1000 mm stroke.

[mm]

Stopping Accuracy

Bore size [mm] 32 40 50 63 80 100

Lock type Exhaust locking

Stopping accuracy [mm]

±1.0

Conditions

· Mounting orientation: Horizontal

· Supply pressure: 0.5 MPa

· Piston speed: 300 mm/s

· Load condition: Upper limit of allowed value

Solenoid valve for locking is mounted on the unlock port.

Maximum value of stopping position dispersion from 100 measurements

Symbol Specifications

-XAmChange of rod end shape

-XC35 With coil scraper

Symbol Specifications

-X3000

Dimensionally compatible with the MNB series

-X3030m

With lock status indication

Made to Order Common Specifications

Click here for details.

Made to Order Individual Specifications

(For details, refer to page 35.)

8

MWBMWBWMWB-UT Model Selection

Double Acting, Single RodDouble Acting, Double RodLock Unit

Made to Order Auto Switch

C