+24V

TD+

TD−

0V

V−

CAN_L

Drain

CAN_H

+24V

RD+

RD−

0V

OUTPUT

INPUT

COM A

+24V

TD+

TD−

0V

+24V

RD+

RD−

0V

OUTPUT

INPUT

COM D

V+

FG

+24V

0V

+24V

0V

q

w

e

r

t

q

w

e

r

q

w

e

r

q

w

e

r

q

w

e

r

q

w

q

w

SW1

OFF

ON

OFF

ON

SW2

MNS

PWR(V)

PWR

654321

ON

10987654321

ON

COM C COM DCOM A COM B

INPUT

Display Setting

Internal Circuit

Flexible I/O Setting Examples

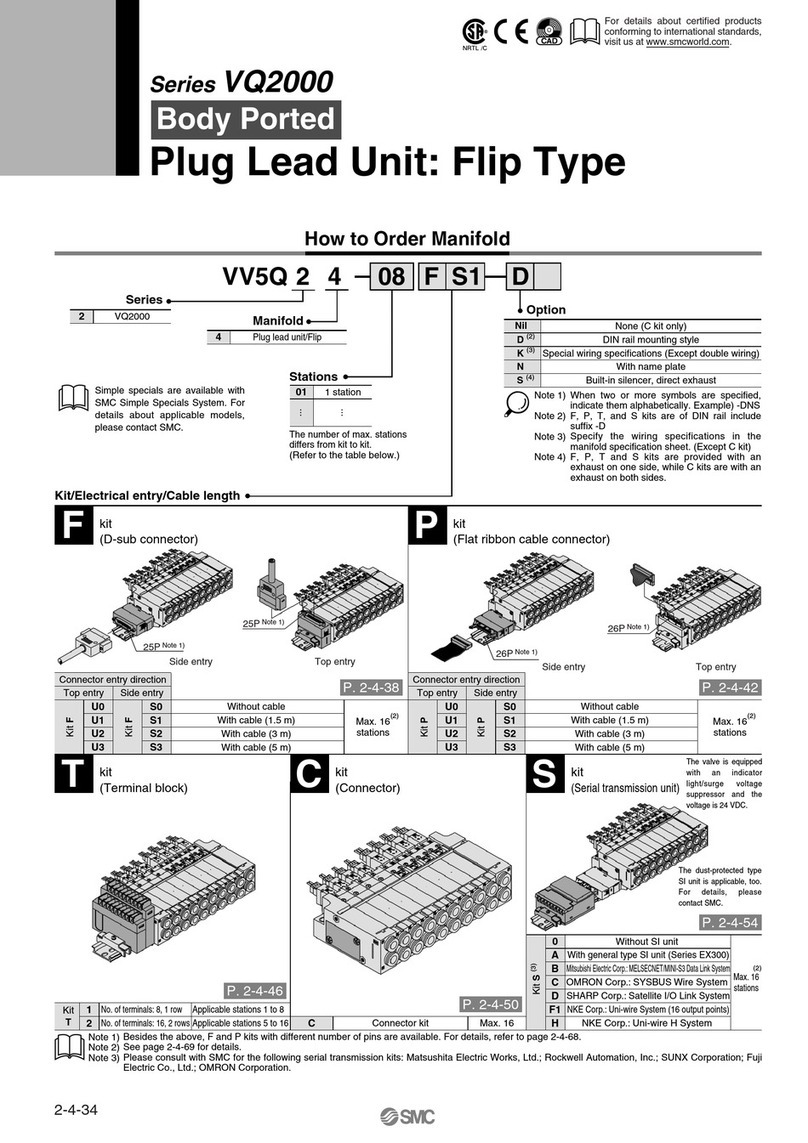

The occupying number of points in the Gateway units can be changed flexibly by setting a switch.

The occupying number of inputs and outputs can be set respectively. (Figures below are examples of the flexibility of setting the output occupied numbers.)

Refer to the operation manual for details.

are parts in use.

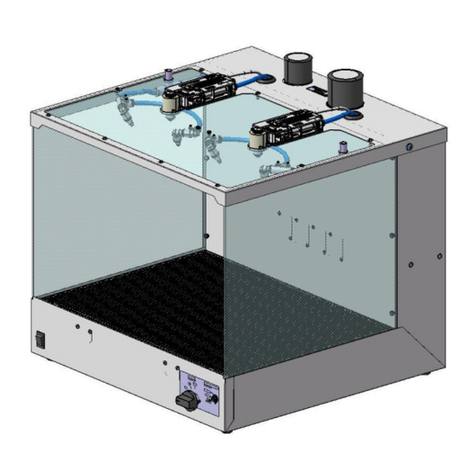

Side view of the Gateway unit

EX510-GDN1 (DeviceNet™ compliant)

Display Contents

Indicator light condition

PWR(V) The output power supply voltage is supplied as specified.

The output power supply voltage is not supplied as specified.

Light is turned on.

Light is turned off.

PWR When the input and the power for the Gateway is being supplied.

When the input and the power for the Gateway is not being supplied.

Light is turned on.

Light is turned off.

MNS

When the power supply is OFF, off-line, or checking the MAC ID duplication.

When I/O connection is on stand by. (On-line state)

I/O connection installation is completed. (On-line state)

I/O connection, time-out (communication irregularity in light degrees)

MAC ID duplication error, or BUS OFF error (communication error in

serious conditions)

Light is turned off.

Green light blinks.

Green light is

turned on.

Red light blinks.

Red light is turned

on.

COM

A to D

When COM A to D are receiving data.

When COM A to D are not receiving data.

Light is turned on.∗

Light is turned off.

∗ Input unit (Input device) is connected and will illuminate when communication is working properly.

GW System, 4 Branches Series EX510

Address setting

Number of

input settings

Number of

output settings

Communication

speed setting

HOLD/CLR setting

HW/SW setting

DC-DC

converter

(insulated)

Communication

part

Insulation circuit

(Photo-coupler)

CAN

transceiver

DC-DC

converter

(not insulated)

(Brown)

Power supply

for the input and

for the control unit

of the Gateway

Power supply

for output

Input/Output total 128 points

16 inputs

16 inputs

16 inputs

16 inputs

16 outputs

16 outputs

16 outputs

16 outputs

Input/Output total 64 points

16 inputs

16 inputs

16 inputs

16 inputs

Input/Output total 80 points

16 inputs

16 inputs

16 inputs

16 inputs

8 outputs

8 outputs

Input/Output total 80 points

16 inputs

16 inputs

16 inputs

16 inputs 16 outputs

Input/Output total 96 points

16 inputs

16 inputs

16 inputs

16 inputs

8 outputs

8 outputs

8 outputs

8 outputs

Input/Output total 96 points

16 inputs

16 inputs

16 inputs

16 inputs

16 outputs

16 outputs

Internal circuit

Input: 16 inputs 4-branch settings

Output: 16 outputs 4-branch settings

Input: 16 inputs 4-branch settings

Output: Unused settings

Input: 16 inputs 4-branch settings

Output: 8 outputs 2-branch settings

(at the time of shipping)

Input Output Input Output Input Output

Input: 16 inputs 4-branch settings

Output: 16 outputs 1-branch setting

Input: 16 inputs 4-branch settings

Output: 8 outputs 4-branch settings

Input: 16 inputs 4-branch settings

Output: 16 outputs 2-branch settings

Input Output Input Output Input Output

2133