EN 6

speedtimerhasexpireditreturnstothethirdspeedbydefault.

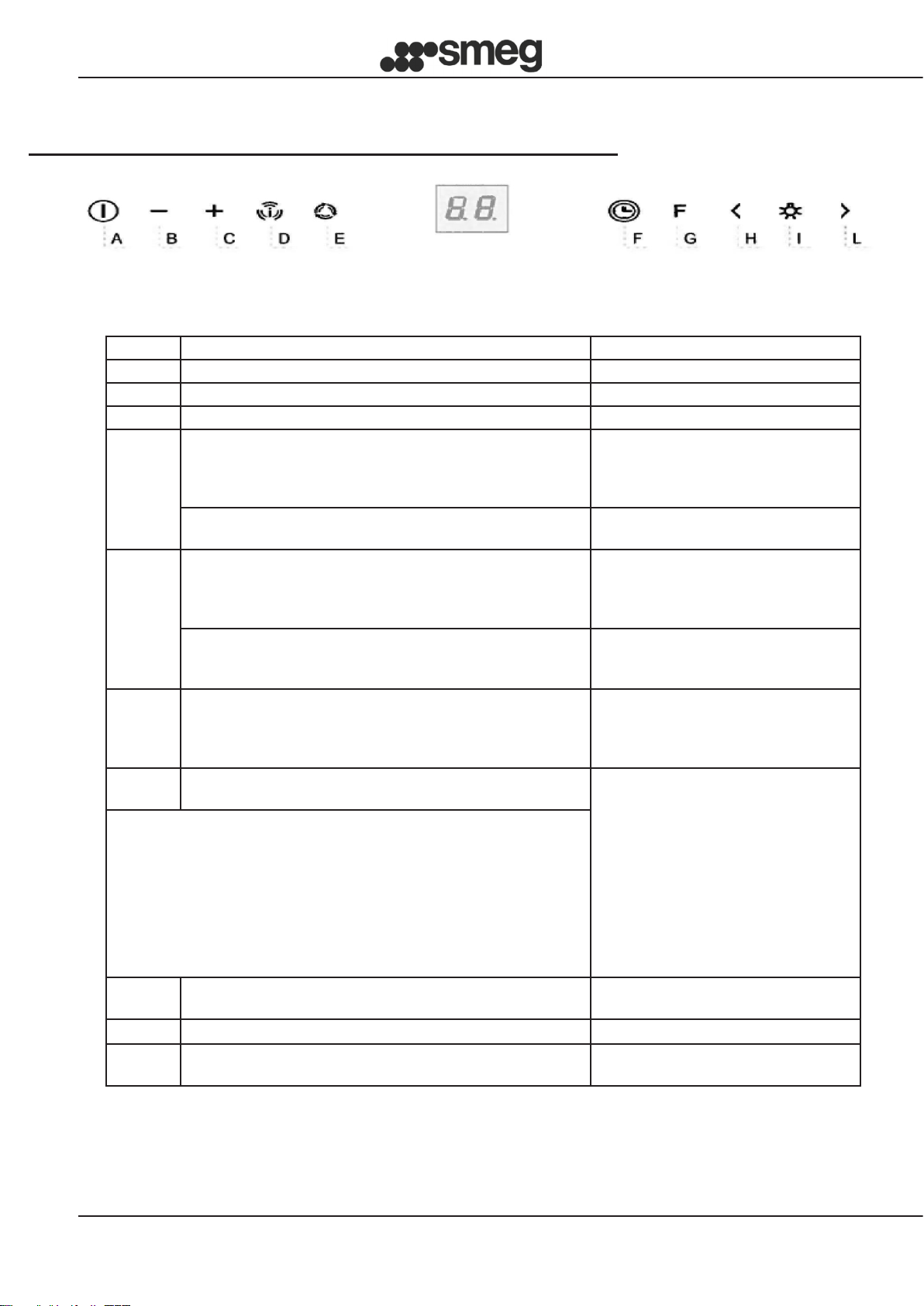

Control panel

2-DIGIT10-KEYCAPACITIVEPUSHBUTTONBOARD:

Key Function Display

ATurns the suction motor on / off. Displays the set speed

BDecreases the operation speed. Displays the set speed

CIncreases the operation speed. Displays the set speed

DActivates the Intensive speed from any speed even with the

motor off, this speed is timed. At the end, the system returns

to the speed previously set. Suitable for dealing with the

maximum emissions of cooking fumes.

Displays alternately HI

Hold the button down for about 5 seconds, when all loads are

off (Motor + Light), to switch the keyboard lock On / Off.

"- -" Keyboard lock On.

E24 H function

Activates the motor at the rst speed and allows extraction for

10 minutes every hour.

It displays 24 and the point at the bottom

right ashes once a second, while the

motor is in operation. Press the key to

disable it.

Holding the button down for about 5 seconds when all loads

are off (Motor + Light), holding key "B" down during the

animation, the Active Carbon Filters Alarm switches On / Off.

Displays a rotary animation for 5

seconds. "EF" ashes twice in activation.

"EF" ashes once in deactivation.

FDelay function

Enables the automatic shutdown delay of 30'. Suitable for

removing residual odours. Can be activated from any position.

You disable it by pressing the key or turning the motor off.

Displays the operating speed and the

point on the lower right ashes.

GWith the lter alarm in progress, pressing the key for about 3

seconds resets the alarm.

After the procedure, the signal

previously displayed turns off:

FF signals the need to wash the metallic

grease lters. The alarm comes on after

100 hours of actual operation of the

Hood.

EF signals the need to replace the active

carbon lters and the metallic grease

lters must also be washed. The alarm

comes on after 200 hours of actual

operation of the Hood.

HDecreases the light intensity at each press of the Key in a cyclic

manner.

1Turns the lighting system on and off at maximum intensity.

LIncreases the light intensity at each press of the Key in a cyclic

manner.