2

2

INDICE

CONSIGLI E SUGGERIMENTI.............................................................................................................................................. 3

CARATTERISTICHE.............................................................................................................................................................. 6

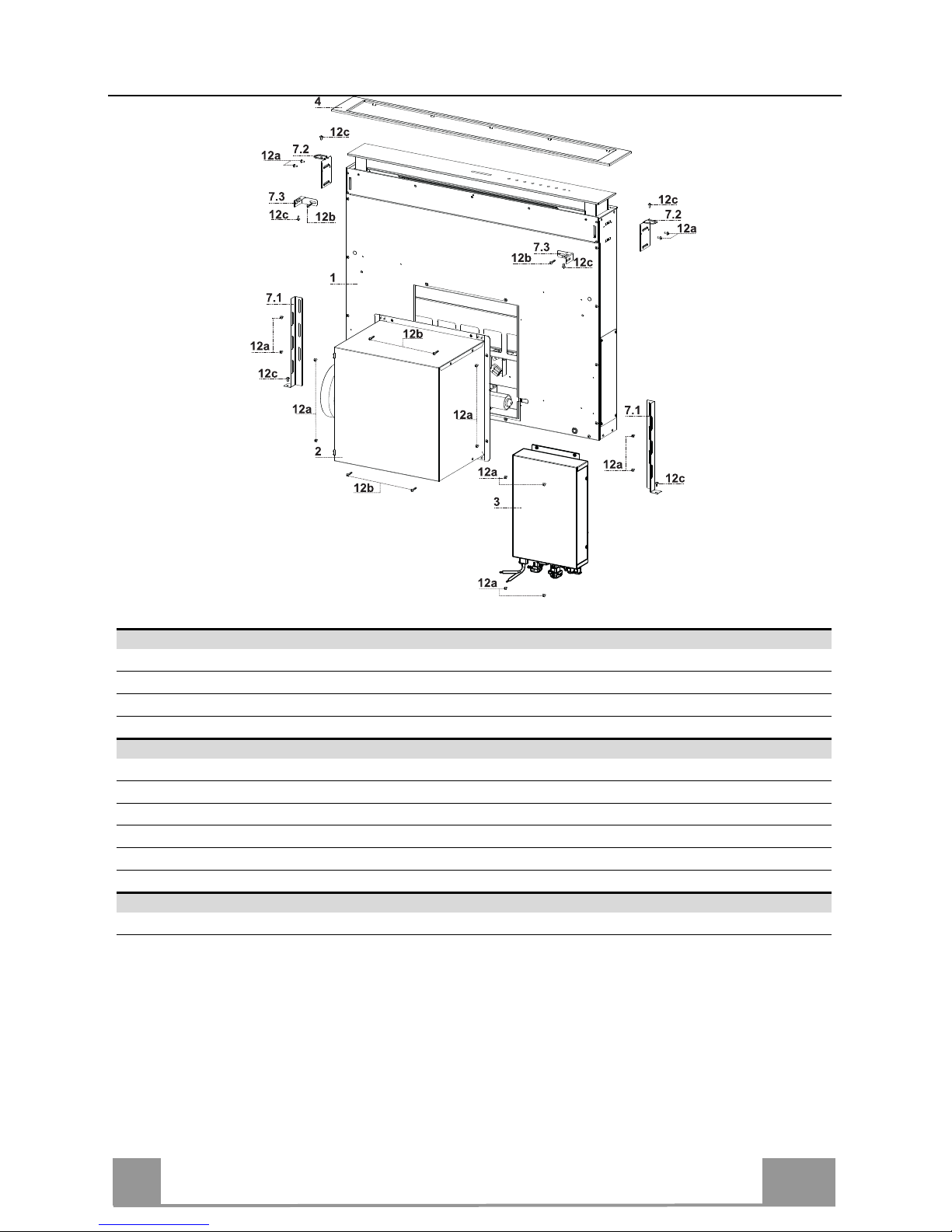

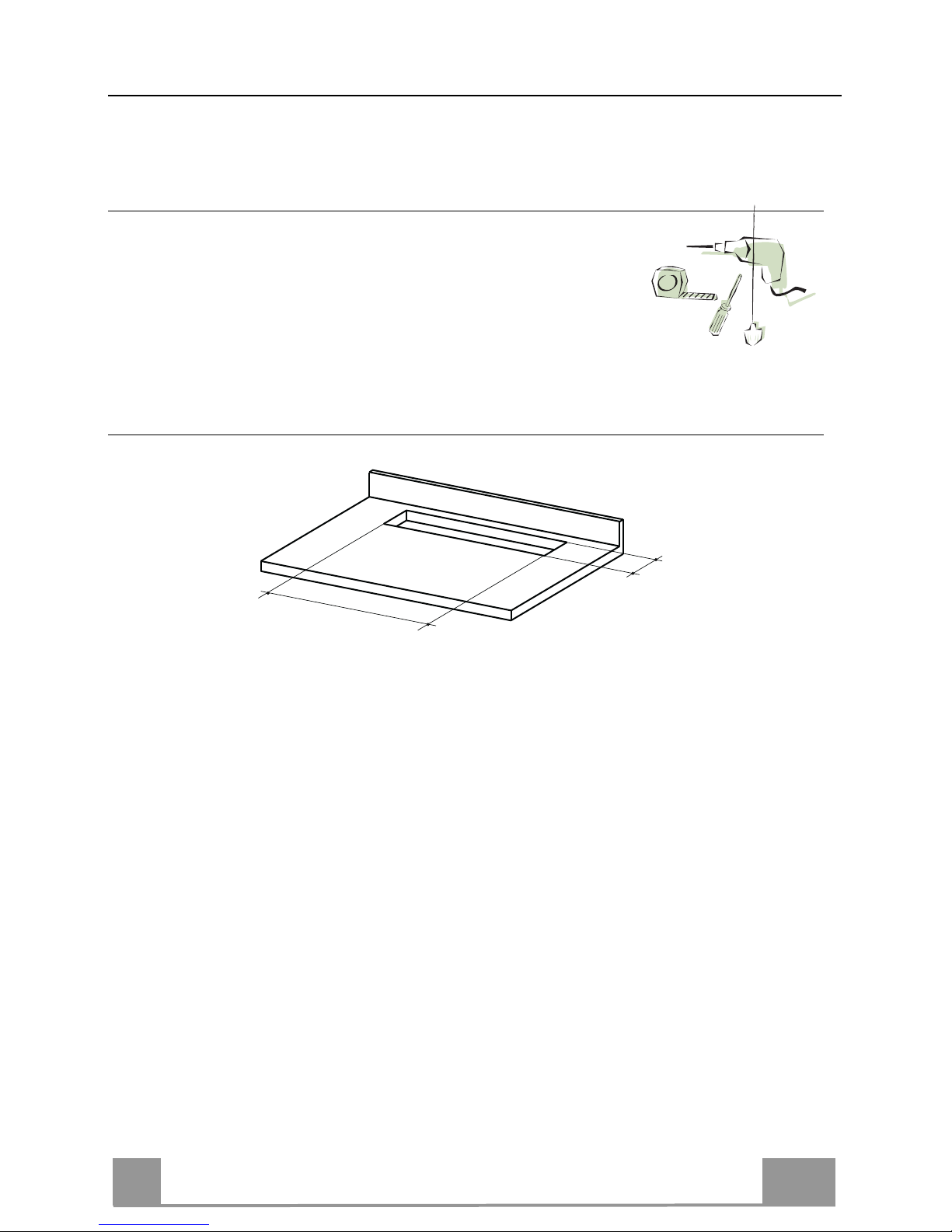

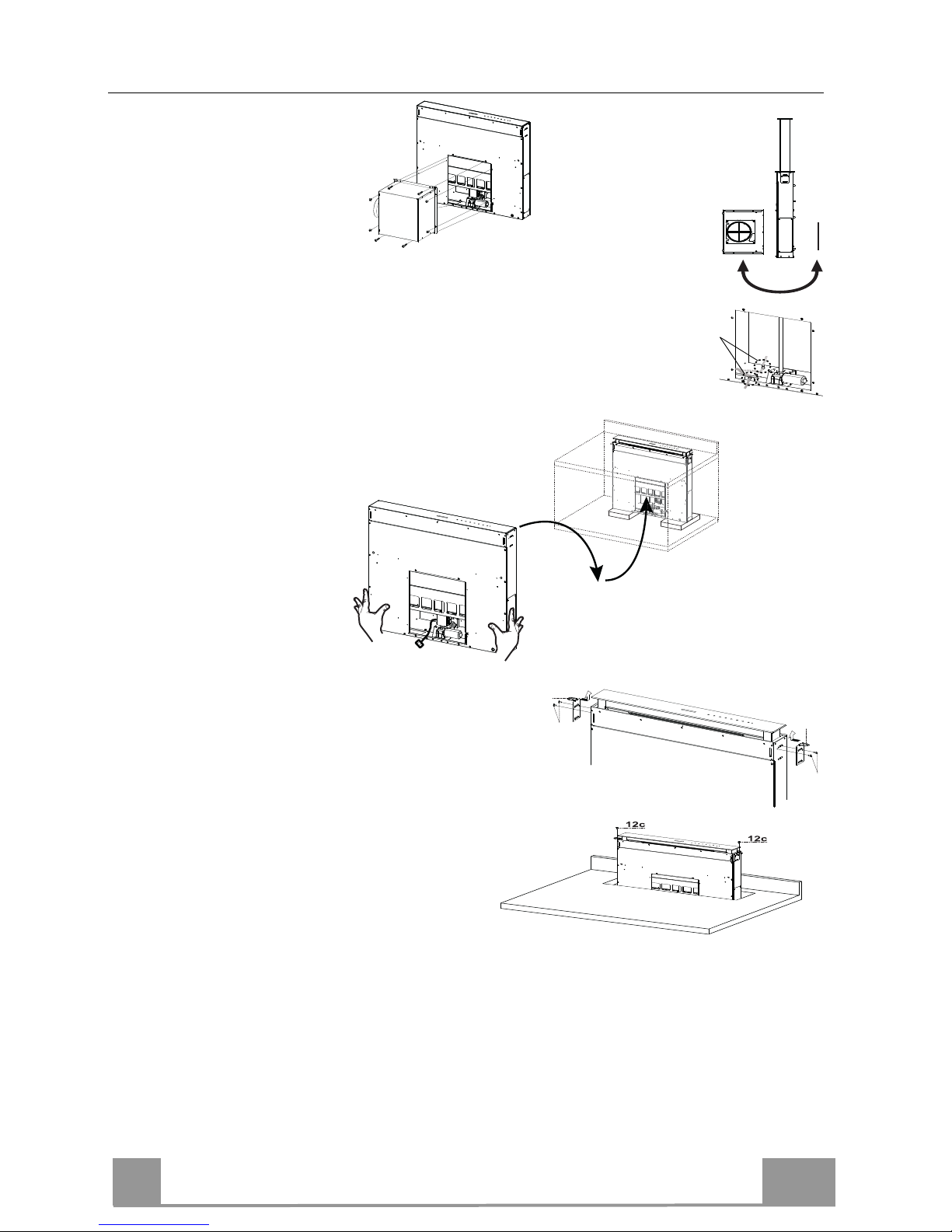

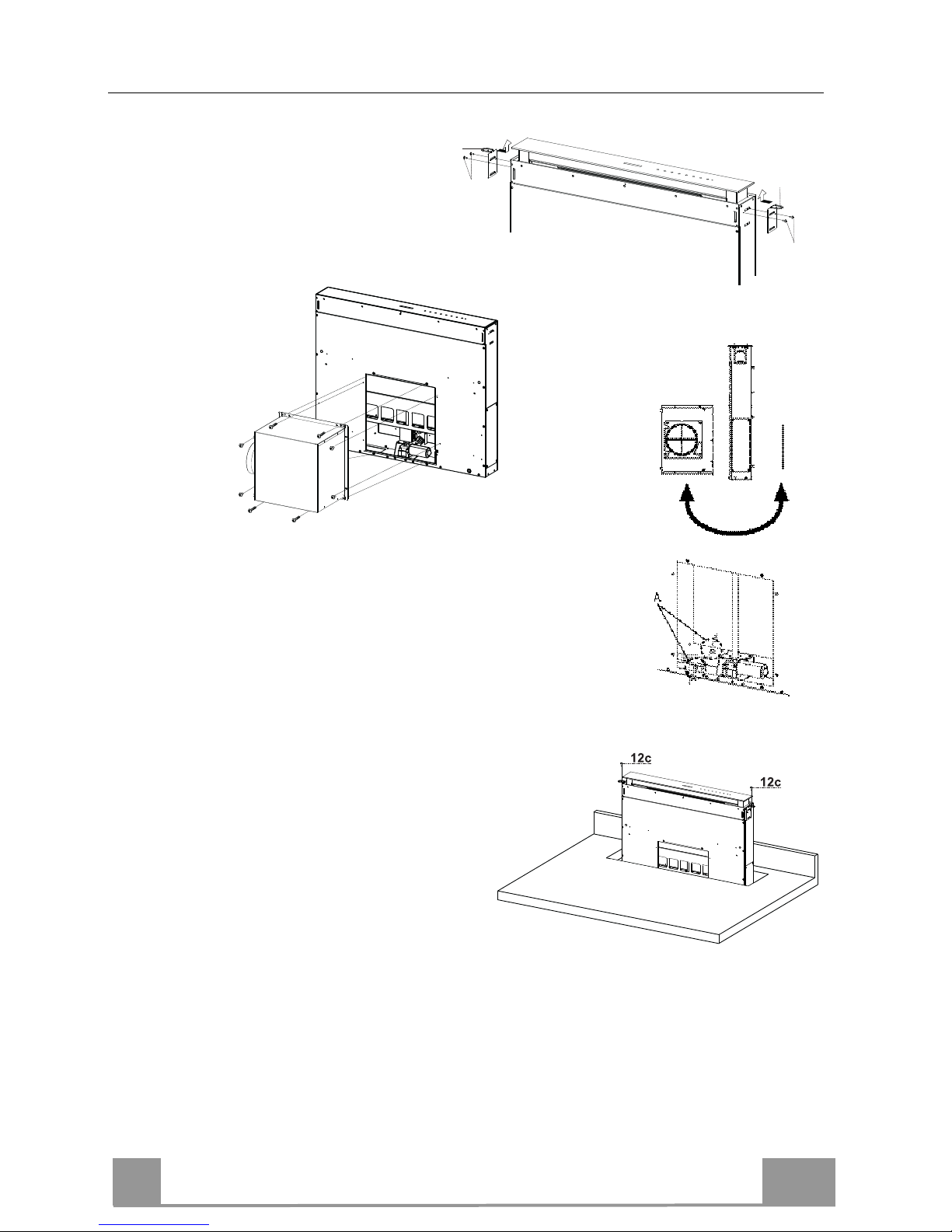

INSTALLAZIONE...................................................................................................................................................................8

USO...................................................................................................................................................................................... 18

MANUTENZIONE ................................................................................................................................................................ 20

INDEX

RECOMMENDATIONS AND SUGGESTIONS...................................................................................................................22

CHARACTERISTICS...........................................................................................................................................................25

INSTALLATION.................................................................................................................................................................... 27

USE......................................................................................................................................................................................37

MAINTENANCE...................................................................................................................................................................39

SOMMAIRE

CONSEILS ET SUGGESTIONS..........................................................................................................................................41

CARACTERISTIQUES.........................................................................................................................................................44

INSTALLATION.................................................................................................................................................................... 46

UTILISATION.......................................................................................................................................................................56

ENTRETIEN......................................................................................................................................................................... 58

INHALTSVERZEICHNIS

EMPFEHLUNGEN UND HINWEISE................................................................................................................................... 60

CHARAKTERISTIKEN.........................................................................................................................................................63

MONTAGE........................................................................................................................................................................... 65

BEDIENUNG........................................................................................................................................................................75

WARTUNG...........................................................................................................................................................................77

INHOUDSOPGAVE

ADVIEZEN EN SUGGESTIES............................................................................................................................................. 79

EIGENSCHAPPEN..............................................................................................................................................................82

INSTALLATIE.......................................................................................................................................................................84

GEBRUIK.............................................................................................................................................................................94

ONDERHOUD...................................................................................................................................................................... 96

IT

EN

FR

DE

NL