1

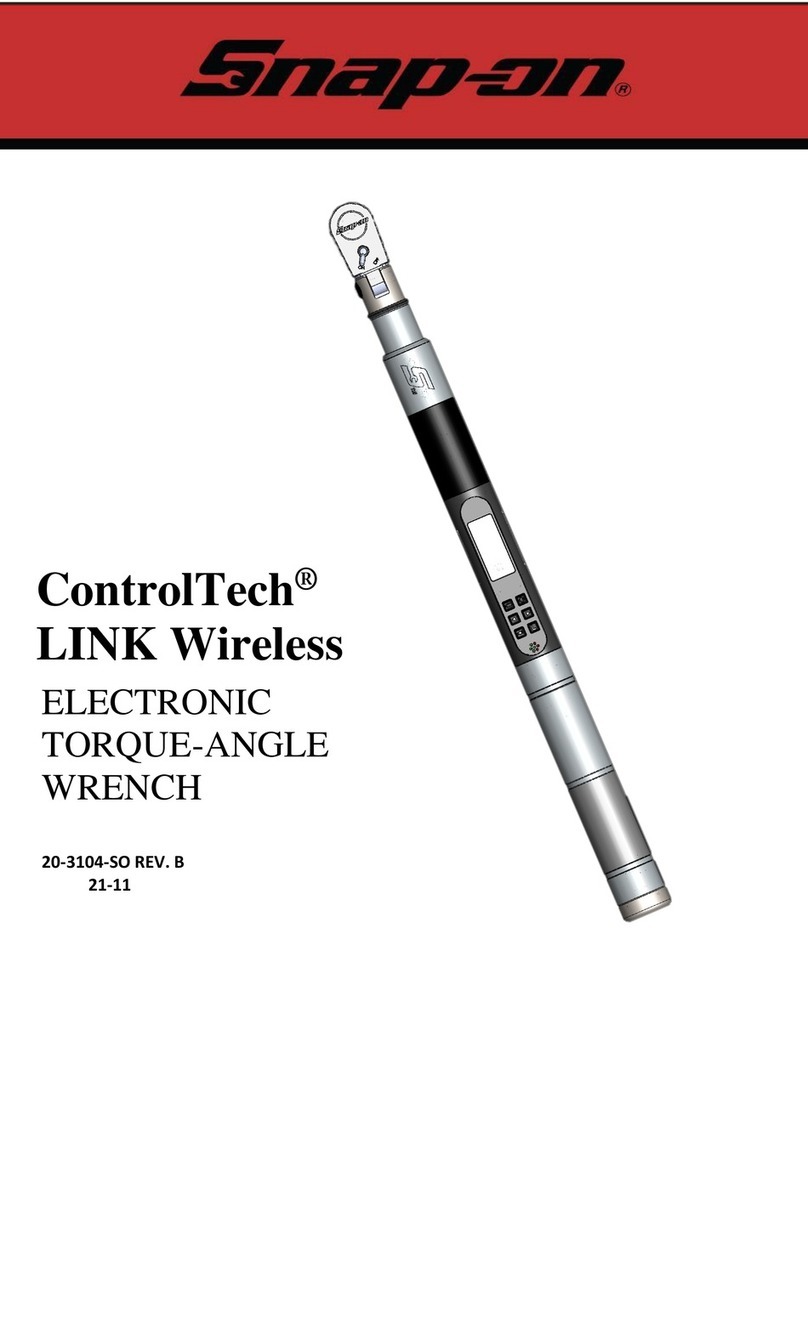

IMPORTANT SAFETY INSTRUCTIONS

WARNING Risk of flying particles.

Over-torquing can cause breakage. Force against flex stops on flex head can cause

head breakage. An out of calibration angle wrench can cause part or tool

breakage. Broken hand tools, sockets or accessories can cause injury. Excess force

can cause crowfoot or flare nut wrench slippage.

Read this manual completely before using ELECTRONIC WRENCH.

To ensure accuracy, work must not move in angle mode.

For personal safety, and to avoid wrench damage, follow good professional

tool and fastener installation practices.

Periodic recalibration is necessary to maintain accuracy.

Wear safety goggles, user and bystanders.

Be sure all components, including all adaptors, extensions, drivers and sockets

are rated to match or exceed torque being applied.

Observe all equipment, system and manufacturer's warnings, cautions and

procedures when using this wrench.

Use correct size socket for fastener.

Do not use sockets showing wear or cracks.

Replace fasteners with rounded corners.

To avoid damaging wrench: Never use wrench with power off. Always turn ON

wrench so applied torque is being measured.

Do not press POWER while torque is applied or while wrench is in motion.

Never use this wrench to break fasteners loose.

Do not use extensions, such as a pipe, on handle of wrench.

Check that wrench capacity matches or exceeds each application before

proceeding.

Verify calibration if dropped.

Make sure ratchet direction lever is fully engaged in correct position.

Verify calibration of wrench if you know or suspect its capacity has been

exceeded.

Do not force head of flex head drives against stops.

Always pull - do not push - on wrench handle and adjust your stance to

prevent a possible fall should something give.

Do not attempt to recharge Lithium cells.

Store wrench in dry place.

Remove batteries when storing wrench for periods longer than 3 months.

WARNING Electrical Shock Hazard.

Electrical shock can cause injury. Plastic handle is not insulated.

Do not use on live electrical circuits.

SAVE THESE INSTRUCTIONS

Disclaimer

Operation of TechAngle®Steel Micro Wrench is not warranted in an EU member state

if operating instructions are not in that State’s language. Contact Snap-on if a

translation is needed.