SNBC KIOSK Series User manual

BK-L216II Manual

SNBC

SNBC

USER MANUAL

KIOSK Series Printers

(BK-L216II)

Compiled by: Date:

Reviewed by: Date:

Date:

Reviewed by:

Approved

by : Date:

Shandong New Beiyang Information

Technology Co., Ltd.

No.169 Huoju Road, Hi-Tech Zone

Weihai city, Shandong, CHINA

Tel: +86—631—5673777

Fax: +86—631—5673778

BK-L216II Manual

Declaration

Information in this document is subject to change without notice. SHANDONG NEW BEIYANG INFORMATION

TECHNOLOGY CO., LTD. (hereinafter referred to as “SNBC”) reserves the right to improve products as new technology,

components, software, and firmware become available. If users need further data about these products, please feel free to

contact our market department or our local distributor.

No part of this document may be reproduced or transmitted in any form or by any means, electronic or mechanical, for any

purpose without the express written permission of SNBC.

zCopyright

This manual was published in 2007 with copyright belonging to SNBC, China

Version: 1.0

zTrademarks: Our registered trademark is and

zMarks means

Warning Items shall be strictly followed to avoid injury or damage to body and equipment.

Caution Items with important information and prompts for operating the printer.

Heating The print head is a thermal element, please do not touch it and its peripherals for safety

reasons.

Warning To prevent damage caused from static electricity, do not touch either its printing part or

connecting parts.

zThe quality control system of SNBC has been approved by the following certification.

DNV ISO9001: 2000

BK-L216II printer has been also approved by the environmental management system as below:

SNBC - 2 -

BK-L216II Manual

SNBC - 3 -

Safety Instructions

Before installing and using the printer, please read the following items carefully.

zInstall the printer in a flat and stable place.

zReserve adequate space around the printer so that the operation and maintenance can be performed conveniently.

zKeep the printer far away from water source.

zDo not use or store the printer in a place exposed to heat of fire, moisture and serious pollution and do not expose the

printer to direct sunlight, strong light and heater.

zDo not place the printer in a place exposed to vibration and impact.

zNo dew condensation is allowed to the printer. In case of such condensation, do not turn on the power until it has

completely gone away.

zConnect the DC adapter to an appropriate grounding outlet. Avoid sharing one electrical outlet with large power

motors and other devices that may cause the fluctuation of voltage.

zDisconnect the DC adapter when the printer is deemed to idle for a long time.

zDon’t spill water or other electric materials into the printer. In case this happens, turn off the power immediately.

zDo not allow the printer to start printing when there is no recording paper installed, otherwise the print head and platen

roller will be damaged.

zTo ensure quality print and normal lifetime, use recommended paper or its equivalent.

zShut down the printer when connecting or disconnecting interfaces connectors to avoid damages to control board.

zSet the print darkness to a lower grade as long as the print quality is acceptable. This will help to keep the print head

durable.

zDo not disassemble the printer without permission of a technician, even for repairing purpose.

zKeep this manual carefully in hand for usage and reference.

BK-L216II Manual

SNBC - 4 -

CONTENT

1. General description..................................................................................... 6

1.1 Introduction ....................................................................................................................6

1.2 Main features .................................................................................................................6

2. Specifications .............................................................................................. 7

2.1 Technical Specifications .................................................................................................7

2.2 Paper Specifications ......................................................................................................8

3. Structure and functions ............................................................................. 10

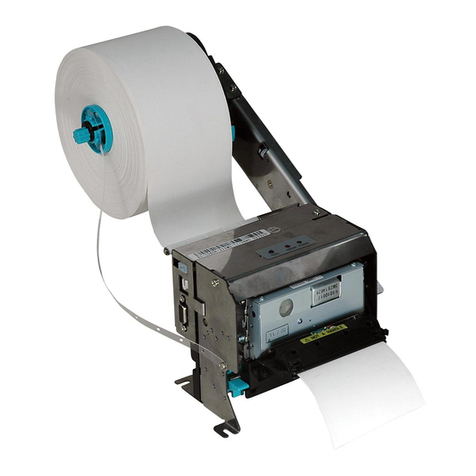

3.1 Appearance..................................................................................................................10

3.2 External Dimension...................................................................................................... 11

3.3 Printer mechanism.......................................................................................................15

3.3.1 Printer mechanism module appearance (without paper holder) ...............................................15

3.3.2 Printer mechanism module explanation ...................................................................................15

3.4 Presenter module ........................................................................................................16

3.4.1 Appearance..............................................................................................................................16

3.4.2 Presenter parts explanation .....................................................................................................17

3.5 Paper holder ................................................................................................................18

3.5.1 Paper holder appearance.........................................................................................................18

3.5.2 Paper holder module explanation.............................................................................................18

3.6 Interface.......................................................................................................................19

4. Installation and suggestion........................................................................ 20

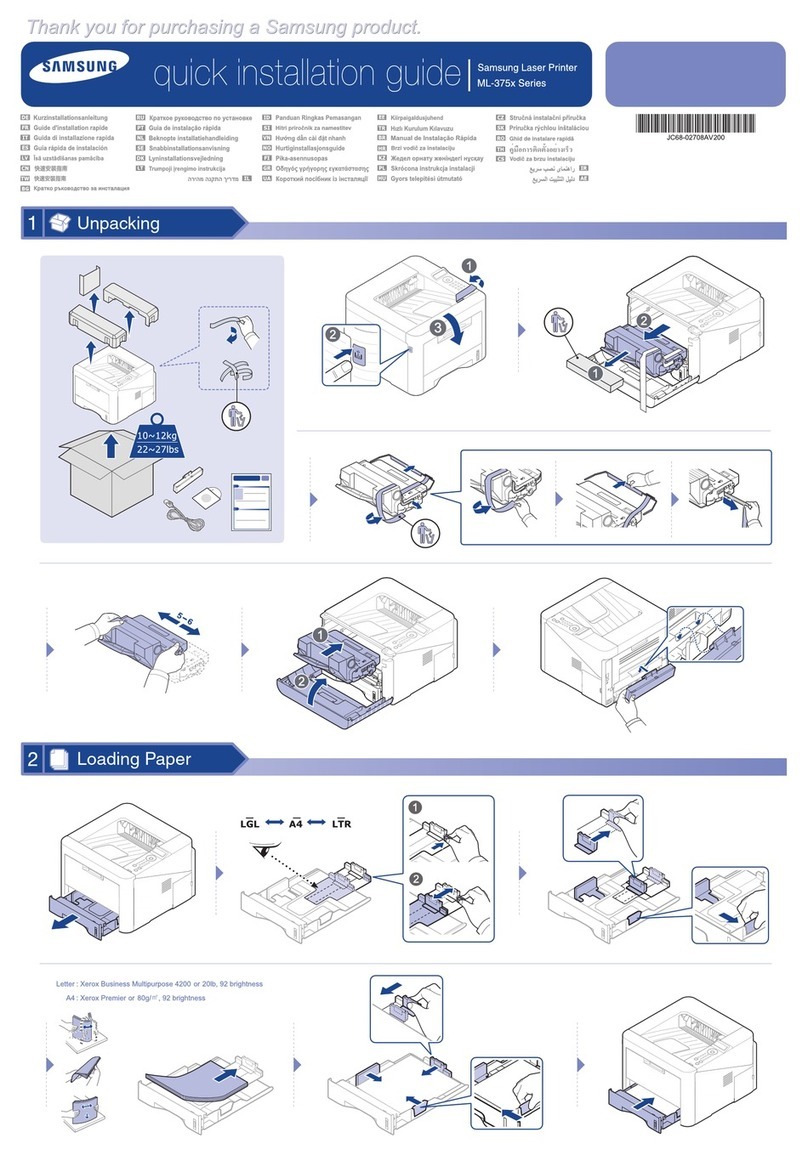

4.1 Unpacking....................................................................................................................20

4.2 Assembling the printer(for vertical and horizontal type)...........................................20

4.3 Connecting the grounding wire ....................................................................................20

4.4 Connecting the AC power adapter ...............................................................................21

4.5 Connecting interface cable ..........................................................................................21

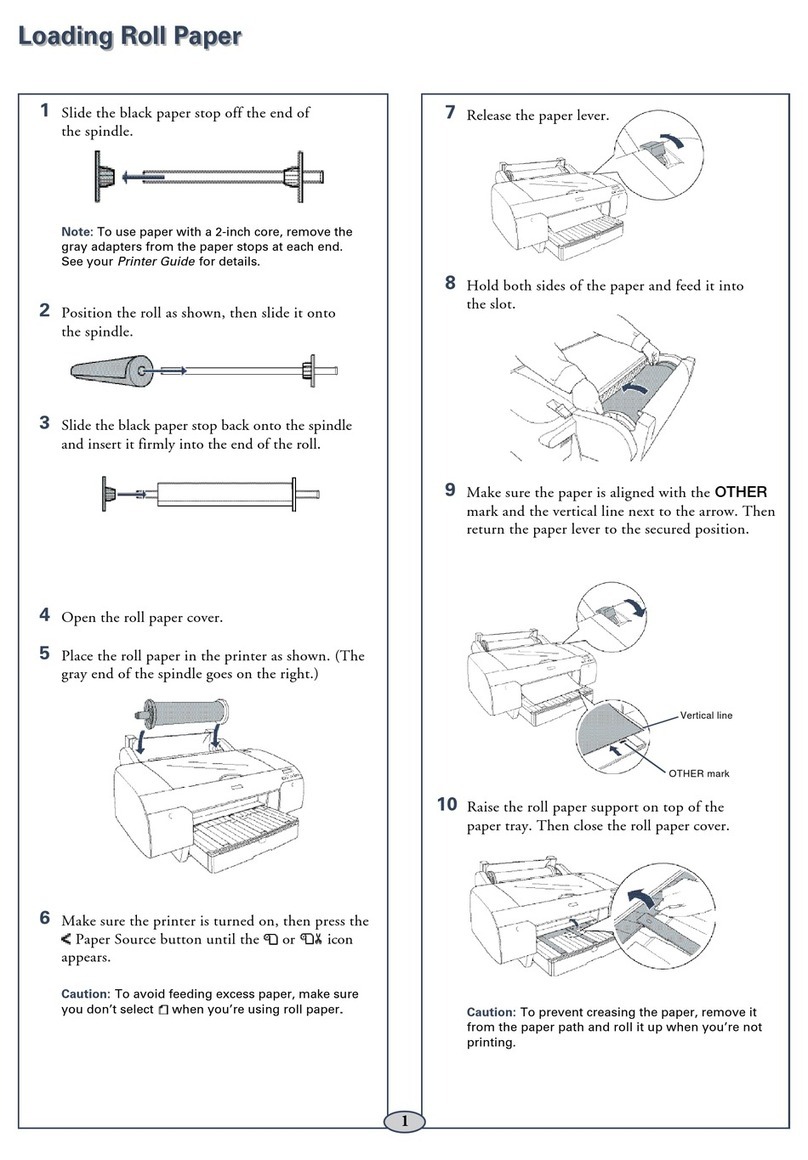

4.6 Loading paper roll ........................................................................................................22

4.6.1 Loading process.......................................................................................................................22

4.6.2 Semi-automatic paper loading or manual paper loading ..........................................................24

4.7 Installing the printer......................................................................................................25

4.8 Installing printer driver..................................................................................................32

5 Routine maintenances ............................................................................... 33

5.1 Cleaning print head......................................................................................................33

5.2 Cleaning sensors .........................................................................................................33

5.2.1 Cleaning paper end sensor ......................................................................................................33

5.2.2 Cleaning paper loading sensor.................................................................................................33

5.2.3 Cleaning paper out sensor .......................................................................................................34

5.2.4 Paper retract sensor.................................................................................................................34

BK-L216II Manual

SNBC - 5 -

5.3 Cleaning printing platen ...............................................................................................35

5.4 Manual resetting cutter ................................................................................................35

5.5 Manual removal of the jammed paper..........................................................................36

6 Interface signal........................................................................................... 36

6.1 RS-232 Interface..........................................................................................................36

6.1.1 Parameter ................................................................................................................................36

6.1.2 Interface linking terminal distribution and signal function .........................................................37

6.2 IEEE1284 Parallel interface (optional) .........................................................................37

6.2.1 Parameters ..............................................................................................................................37

6.2..2 The influence of printer status to parallel interface (/FAULT pin and PE pin)...........................37

6.2.3 Parallel interface signal ............................................................................................................37

6.2.4 Time sequence of data receiving..............................................................................................39

6.3 USB interface (optional)...............................................................................................39

6.3.1 Power interface ........................................................................................................................39

7 Troubleshooting and maintenance............................................................. 40

7.1 Common errors and settlement ...................................................................................40

7.1.1 Problems during paper loading ................................................................................................40

7.1.2 Problems during printing ..........................................................................................................41

7.1.3 Problems during paper out.......................................................................................................41

7.1.4 Other problems ........................................................................................................................41

Appendix ....................................................................................................... 42

Appendix 1 Self-test page..................................................................................................42

Appendix 2 Tool software...................................................................................................45

Appendix 2.1 Debugging Software ....................................................................................45

Appendix 2.2 BKMonitor program......................................................................................46

Appendix 2.3 KIOSKUtility Tool .......................................................................................46

BK-L216II Manual

1. General description

1.1 Introduction

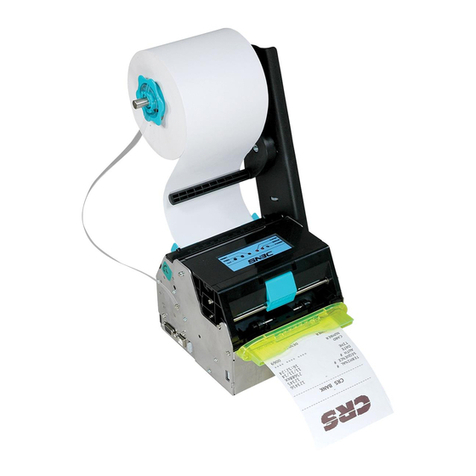

BK-L216II is a high performance thermal printer with cutter and presenter as optional and can accept up

to 203mm (Outer diameter) paper rolls. The maximum print width is 216mm. It can be widely used in

Kiosk applications like data communication terminal, test instrument terminal and information consulting

terminal etc.

BK-L216II consists of the following modules.

zThermal printing unit zPaper holder (optional, or not configured )

zPresenter (optional or with paper out path

structure)

zControl board

zCutter

According to different paper roll installation mode, BK-L216II has models in horizontal and vertical

structures for customers to select. BK-L216II can be connected with other devices by serial interface and

parallel interface, or serial interface and USB interface. Drivers are available for

Win95/98/NT4.0/2000/XP/LINUX. BK-L216II could be operated and maintained very easily.

1.2 Main features

zPrinting

High-speed printing

Thermal print with low noise

High reliability

zPresenter

Accommodate and present printout

Retract printout after waiting time

Hold printout for user to take away

zApplications

Its commands are compatible with ESC/POS standard;

Character processing: 1-6 times enlargement vertically and horizontally, Rotation

0

SNBC - 6 -

(0 , 900, 1800, 2700), white/black reverse, underline, inverse;

Barcode printing is Barcode printing is available by using a bar code command. Barcodes

can be printed both in the vertical direction and in the horizontal direction.

Character font size (font A or font B) can be selected via a command.

zPrinter maintenance

Easy paper roll loading

Easy Print head cleaning

Various features and parameters can be selected by using a software tool

Auto paper cutting

Semi-automatic paper loading

BK-L216II Manual

SNBC - 7 -

Mark identification and checkout

Updating firmware online

2. Specifications

2.1 Technical Specifications

Parameter

Items

203dpi Model 300dpi Model

Print method Direct thermal line

Resolution 203dpi 300dpi

Paper Length 210mm-216mm 210mm-216mm

Max.216mm (8.5 ")Max.216mm (8.5 ")

Print Width

Max.1728 点Max.2560 点

Standard mode Max: 305mm

Min: 82.5mm

Print height

Special mode Max: 1000mm

Min: A4/3 (82.5mm)

Print speed 125mm/s 100mm/s

RAM memory SRAM: 8MB

Flash memory 1MB/2MB/4MB

Print head temperature

detecting Thermal resistor

Print head position

detecting Micro switch

Paper / mark detecting Photoelectrical Sensor

Paper near end detecting Photoelectrical Sensor

Interface RS-232,Centronics(optional),USB(optional)

Barcode CODE128,ITF ,UPC-A,UPC-E,EAN13

EAN8 ,CODE39,CODE93,CODABAR, PDF417

English font 0: 12×24

English font 1: 9×17

Big font: 24X24

English font 0: 18×34

English font : 13×24

Big font: 36 X36

Fonts

Big Font(optional)(Simplified Chinese GB2312, traditional Chinese GB18030,

Japanese, Korean)

Fonts Process

All fonts can be enlarged 1 to 6 times vertically and horizontally

respectively ;Rotation Print(00, 900, 1800, 2700)

Bold, white/black reverse, Underline.

Barcodes

Fonts

Graphics

Graphics Support BMP bit Image download to RAM or FLASH

Support direct BMP Print

Paper type Continuous paper / marked paper / folded Paper

Paper roll OD Max.203mm

Paper roll ID Optional: 25.4mm or ≥50mm

Thickness 60~100 um

Medium

Thermal surface Outer side

BK-L216II Manual

SNBC - 8 -

Parameter

Items

203dpi Model 300dpi Model

Input voltage AC 220V±5%, 50/60Hz

Power

Output voltage DC 24V, 2.5A

Paper out speed ≥400mm/s

Paper retracting speed ≥400mm/s

PRESENTER

Function modes Retraction/Hold/Commands control/close

Print head lifetime ≥100Km

Cutter lifetime ≥500,000 (paper thickness:0.08mm)

Reliability

MTBF 360,000 hours

Operation Environment 5°C to 45°C, 20% to 90% RH (40°C)

Environment

Storage Environment -40°C to 60°C, 20% to 93% RH (40°C)

Dimensions 212(L) ×294(W)×97(H)

Physics

Character Weight About 6 Kg (without paper roll and paper holder)

Table 2.1.1 Technical specifications

Note:

zDPI: Dots for each inch in printing (one inch equals to 25.4mm);

zCharacter s space can be adjusted by ESC SP;

zReal print speed is related to the conditions as data transmission speed, print darkness, print duty ratio, commands

used and supply voltage

2.2 Paper Specifications

zPaper type : Continuous paper /marked paper

zPaper supply Method : Paper roll/ Folded paper

zPaper width : 210mm –216mm

zPaper thickness : 60µm-100µm

zThermal layer : Outer side of the roll

zPaper roll specification

: 50mm (inner dimension of standard core)

: 25.4mm or ≥50mm (inner dimension of optional core)

:203mm (maximum paper outer dimension )

zRecommended paper:

¾Continuous paper specification

Paper type Manufacturer

TF50KS-E2C Nippon Paper Industries Co., Ltd

F240AC/F220-VP Mitsubishi Paper Mill Co., Ltd

KF060-FEAH New OJI Paper Co., Ltd.

F70NA FUJI PHOTO FILM CO., LTD

FV230A1 MITSUBISHI PAPER MILL CO., LTD.

Table 2.2.1 Printer recommended paper

BK-L216II Manual

¾Marked paper specification

In marked paper mode, the printer determines cut position by referencing black mark position. Detailed paper should meet

the following requirement besides that of standard paper:

Mark length L1: 20mm ≤L1

Mark height L2: 4mm ≤L2 ≤8 mm

Space between two near Marks L3: 82.5mm ≤L3 ≤305mm

Mark position on paper: Right, middle or left side on non-thermal sensitive surface of paper.

Reflectivity: The reflectivity of black mark shall be less than 15% while the paper itself reflectivity shall exceeds 85%.

There shall be no any patterns or add items on the area between black marks, such as advertisement,

figure and so on.

Figure 2.2.1 Mark position sketch map

Notes:

zMark height can be set by adjusting printer configuration.

zThe paper path has three positions selectable for black mark sensor installation. Only one sensor is mounted on the

right side of the paper path(default) when the printer is delivered(Paper feeding direction).

zWhen the printer is in motionless status, it does not detect any black marks. Therefore, if the paper is pulled away from

it compulsorily, the printer gives no alarm of paper end. This feature design assures that the printer does not alarm

paper end errors when a black mark stops on paper near end sensor of the printer.

¾Folded paper specification

Figure 2.2.2 Relations between folding line position and cutting position

zWhen using folded paper, make sure to keep the folding line outside of the printing area to avoid paper jammed.

zIt is recommended to set the cutting position 0.5 to 2mm below the folding line (reverse to feeding paper direction) to

prevent paper jam.

zRefer to continuous and marked paper specification to decide the position relation between folding line and black

mark.

Notice:

zPlease use the recommended paper or its equivalents. Using other types of paper may affect print quality and reduce

the print head lifetime.

zDo not paste the paper to the shaft core.

SNBC - 9 -

BK-L216II Manual

zIf the paper comes in contact with chemical or oil, it may discolour or be less heat sensitive, which will greatly affect the

print quality.

zDo not rub the paper surface with a nail or hard metal. Otherwise it may discolour.

zWhen the temperature goes up to 70 degrees, paper will discolour. So please be careful to the effect of temperature,

humidity and sunlight in environment.

3. Structure and functions

3.1 Appearance

Figure 3.1.1 Vertical structure

Figure 3.1.2 Horizontal structure

SNBC - 10 -

BK-L216II Manual

Figure 3.1.3 Structure without paper holder

1------------Print unit

2------------Cutter

3------------Cutter label

4------------Presenter upper cover open label

5------------Presenter

6------------Button

7------------Paper holder (for vertical structure only)

8------------Product Label

9------------Print head cover open label

10---------- Paper feed label (for vertical structure only)

11-----------Paper feed label (for horizontal structure and without paper holder type)

12-----------Paper holder (for horizontal structure only)

3.2 External Dimension

SNBC - 11 -

BK-L216II Manual

Figure3.2.1 Dimension without paper holder (212*294*96.7mm)

SNBC - 12 -

BK-L216II Manual

Figure 3.2.2 Dimension of vertical structure (237*294*263mm)

SNBC - 13 -

BK-L216II Manual

Figure 3.2.3 Dimension of horizontal paper holder (335*294*150mm)

SNBC - 14 -

BK-L216II Manual

3.3 Printer mechanism

3.3.1 Printer mechanism module appearance (without paper holder)

Figure 3.3.1 Printing mechanism

1 —Print platen 6 —Paper load sensor 11-Reset button

2 —Print head 7 —Cutter 12-Feed button

3 —Paper sensor 8 —Power LED(Green)13-Cut button

4 —Pressing plate 9 —Alert LED(Red)14-Power switch

5 —Paper guide module 10-Paper end LED(Red)

3.3.2 Printer mechanism module explanation

1. Paper sensor --Detect whether there is paper.

2. Pressing plate for opening cover –When users press down this plate, the print head could be opened

automatically;

3. Paper guide module –It is the path before the printing shown as Fig. 3.3.1 and Fig.3.3.2. The paper guide module

has two parts which can move to right or left so that users could adjust it until the paper lies in the middle of the print

head. Left and right positioning parts can support the paper width from 210 to 216mm;

Figure 3.3.2 Paper guide module

SNBC - 15 -

BK-L216II Manual

4. Paper loading sensor --Detect the position of the front end of paper.

5. Cutter –Execute auto-cut function;

6. Power LED (Green) --To indicate whether the power is on and it lights all the time when the power is turned on;

7. Alert LED –Indicate all status of print. In normal conditions Alert LED is off; In error status (such as paper end) Alert

LED blinks;

8. Paper end LED --When the printer is in paper end status, this LED blinks; If paper is available, Paper End LED is

off;

9. Reset button –When pressing down this button, the printer shall execute its reset automatically and clear the print

data in the printers.

10. FEED button --Under normal status (no error), press to feed paper. Keep pressing for continuous paper

feeding. Turn on the power while pressing this button for one second to print self test page.Content in self

test page changes with the configuration of the printer.

Note: make sure that there is paper in the printer and the print head is not uplifted before starting self test page.

(For self test page , please refer to Appendix 1 printer self test page)

11. Error LED (Red) --This LED is used to indicate different status of the printer. Normally, it isn’t light. When errors

happen (for example, paper end), it will flash to give alarms.

12. CUT button --Press to cut paper under any circumstances (even the printer has errors);

13. Power LED (Green) –To press down “O” can turn off the power; To press down “—“ turn on the power;

3.4 Presenter module

3.4.1 Appearance

Figure 3.4.1 Presenter appearance

SNBC - 16 -

BK-L216II Manual

Figure 3.4.2 Paper out sensor

Figure 3.4.3 Retraction sensor

1.--- Presenter turning board

2.--- Presenter module

3.--- Paper path in presenter

4.--- Paper out sensor

5.--- PrstIn sensor(optional)

3.4.2 Presenter parts explanation

Paper out sensor: to detect paper status

PrstIn sensor(optional): to detect whether paper retracted.

Caution

Paper sensor may be ineffective due to the direct irradiation of sunlight, blazing light and heat source.

SNBC - 17 -

BK-L216II Manual

3.5 Paper holder

3.5.1 Paper holder appearance

Figure 3.5.1 Vertical paper roll holder appearance

Figure 3.5.2 Horizontal paper roll holder appearance

1-Paper roll shaft

2-Paper roll support

3-Paper near end sensor

4-Paper near end sensor inter-connective socket

5-Paper roll locating block (each one on the left and right)

3.5.2 Paper holder module explanation

1) Paper near end sensor

①User may check paper status by sending inquiring command (refer to “command set” for details) to the printer.

②Users can adjust the position of paper near end sensor to control the amount of remaining paper according to

different paper roll diameter (see figure 3.5.1 and 3.5.2). To adjust the sensor, please loose those two fixing screws and

SNBC - 18 -

BK-L216II Manual

move the positioning board up or down to the right position along the slide track then tighten the screws.

2) Paper roll shaft

Paper roll support (2) is needed when a paper roll with a 50 mm ID is used. For paper roll with 25mm ID, use only the

paper roll shaft (1).

3) Paper roll-locating block

Fix paper roll position fixing piece on paper holder only when using a 210mm wide paper roll. For 216mm wide paper,

please remove the paper roll-locating block.

Caution

When you fix or remove paper roll-locating block, you should adjust both left and right paper guide modules (refer to 5 in

3.3.1 printer mechanism module appearance) at the same time to match with different paper width.

3.6 Interface

Figure 3.6.1 Parallel interface model

Figure 3.6.2 USB interface model

1.--- Centronics (parallel interface)

2.--- RS-232

3.--- Power socket

4.--- USB interface

Notice:

Only one kind of interface between parallel and USB can be configured in one printer.

SNBC - 19 -

This manual suits for next models

1

Table of contents

Other SNBC Printer manuals

SNBC

SNBC BK-T6112 User manual

SNBC

SNBC BTP-R681 User manual

SNBC

SNBC BTP-R180II User manual

SNBC

SNBC BTP-L580IIC User manual

SNBC

SNBC BTP-R180II User manual

SNBC

SNBC BK-S216 User manual

SNBC

SNBC BTP-2002NP User manual

SNBC

SNBC BTP-R580 User manual

SNBC

SNBC BTP-R880NPI User manual

SNBC

SNBC BTP-R180II Owner's manual

SNBC

SNBC BTP-M300 User manual

SNBC

SNBC BTP-2002NP User manual

SNBC

SNBC BT-T080 Owner's manual

SNBC

SNBC BTP-R990 User manual

SNBC

SNBC BTP-R880NP User manual

SNBC

SNBC BTP-R880NP Owner's manual

SNBC

SNBC BT-UC056III User manual

SNBC

SNBC BTP-P33 User manual

SNBC

SNBC BTP-R580II Owner's manual

SNBC

SNBC BTP-P36 User manual