Version EN-042020-1.30 3

Table of Contents

Table of Contents

Chapter 1 ...................................................................................... 5

About this guide

............................................................................................................... 51.1 Read me first

............................................................................................................... 51.2 Target audience

............................................................................................................... 51.3 Typographic conventions

............................................................................................................... 61.4 Document history

............................................................................................................... 61.5 Related documentation and videos

............................................................................................................... 61.6 Document feedback

Chapter 2 ...................................................................................... 7

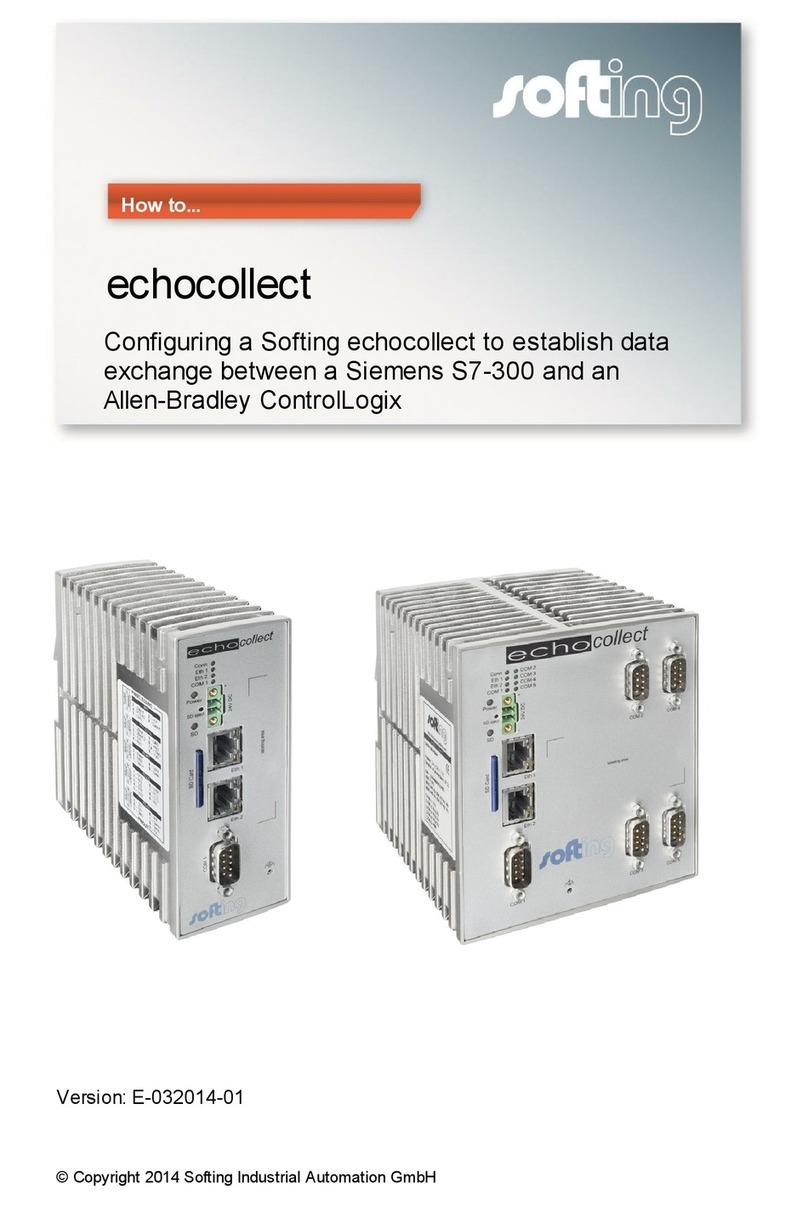

About the PROFINET Gateways

............................................................................................................... 72.1 Intended use

............................................................................................................... 72.2 System requirements

............................................................................................................... 82.3 Supported features

............................................................................................................... 82.4 Specifications

............................................................................................................... 82.5 Safety precautions

Chapter 3 ...................................................................................... 9

Installation

............................................................................................................... 93.1 Hardware installation

.......................................................................................................... 9

Mounting and dismounting3.1.1

.......................................................................................................... 10

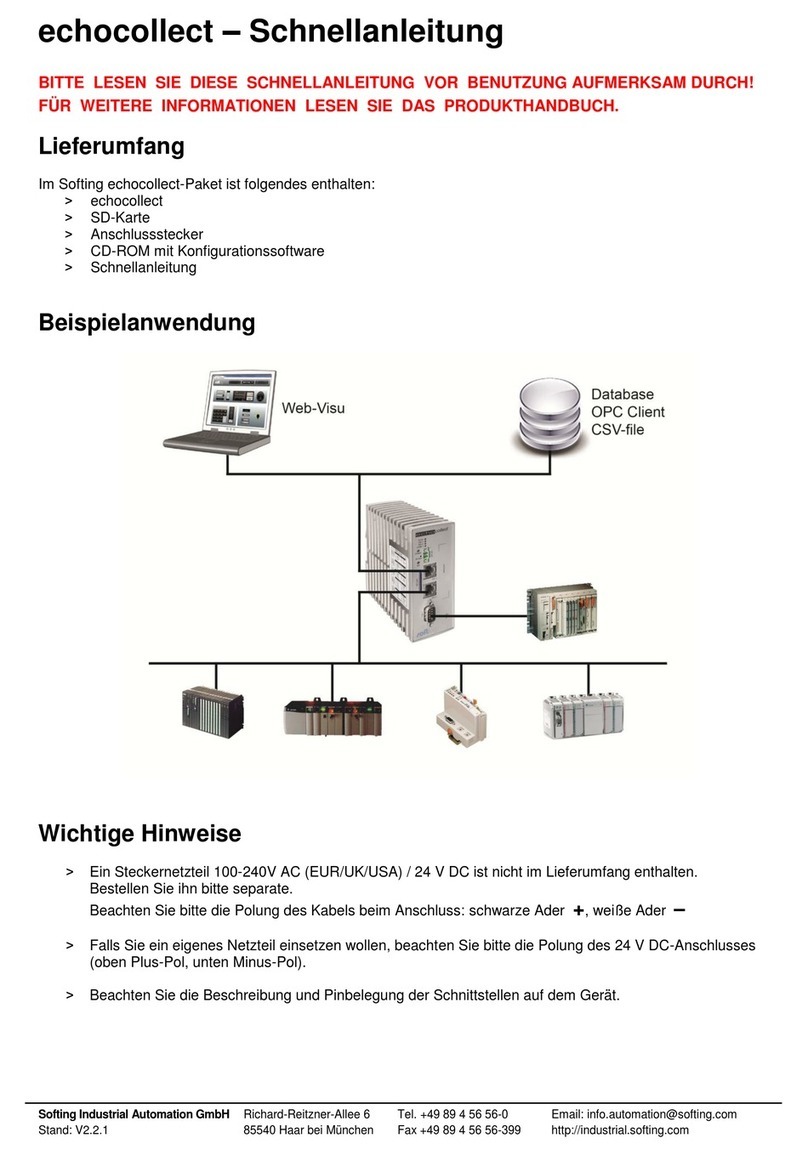

Connection diagrams pnGate PA3.1.2

.......................................................................................................... 11

Connection diagram pnGate PB3.1.3

.......................................................................................................... 11

Connection diagram pnGate DP3.1.4

.......................................................................................................... 12

Connecting the power supply3.1.5

.......................................................................................................... 13

Connecting to the network3.1.6

.......................................................................................................... 14

Installation positions3.1.7

.......................................................................................................... 16

Powering up the device3.1.8

............................................................................................................... 173.2 Software installation

Chapter 4 ...................................................................................... 18

Configuration

............................................................................................................... 184.1 Prerequisites

............................................................................................................... 184.2 Changing the IP address of the PROFINET Gateway

............................................................................................................... 204.3 Setting the IP address of the PC

............................................................................................................... 214.4 Login to user interface

............................................................................................................... 224.5 Changing the password

............................................................................................................... 244.6 Updating the firmware

............................................................................................................... 254.7 PROFINET configuration in the TIA Portal

.......................................................................................................... 25

Prerequisites4.7.1

.......................................................................................................... 25

Creating a GSDML import file4.7.2