Sony SAL-24105 User manual

Other Sony Camera Accessories manuals

Sony

Sony VF 37PK/S User manual

Sony

Sony VG-B50AM Marketing User manual

Sony

Sony VCT-1170RM User manual

Sony

Sony HDVF-EL100 User manual

Sony

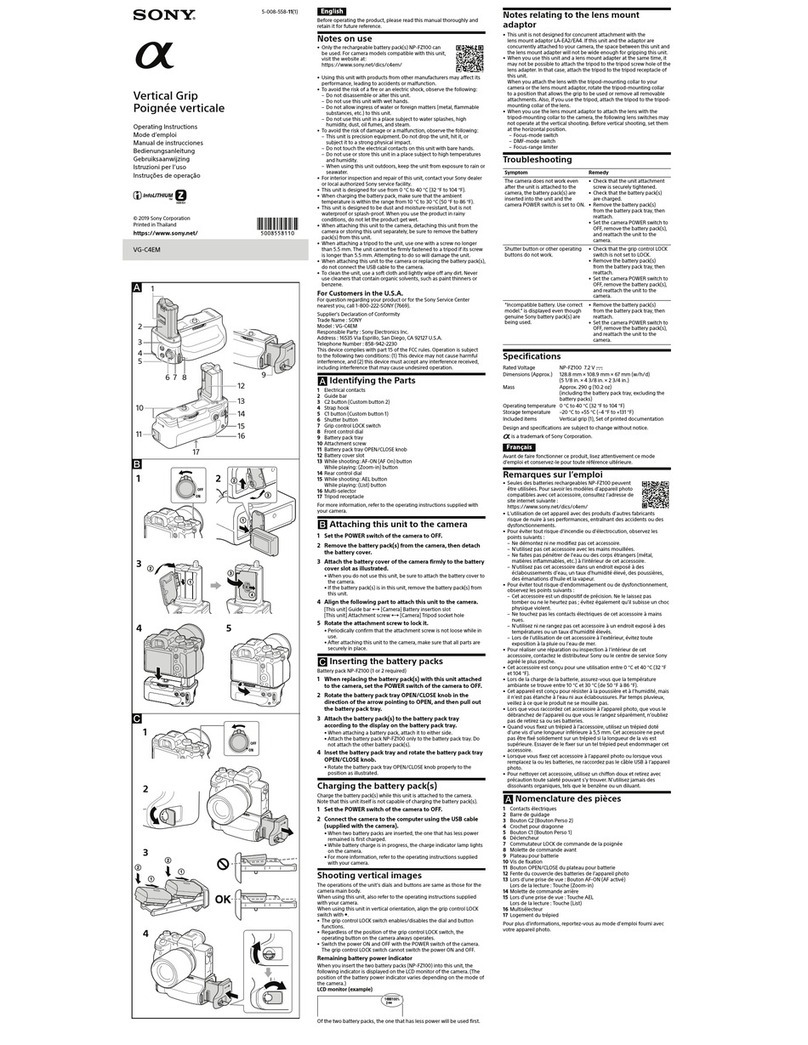

Sony VG-C4EM User manual

Sony

Sony XCD-V60 User manual

Sony

Sony VCT-EXC1 User manual

Sony

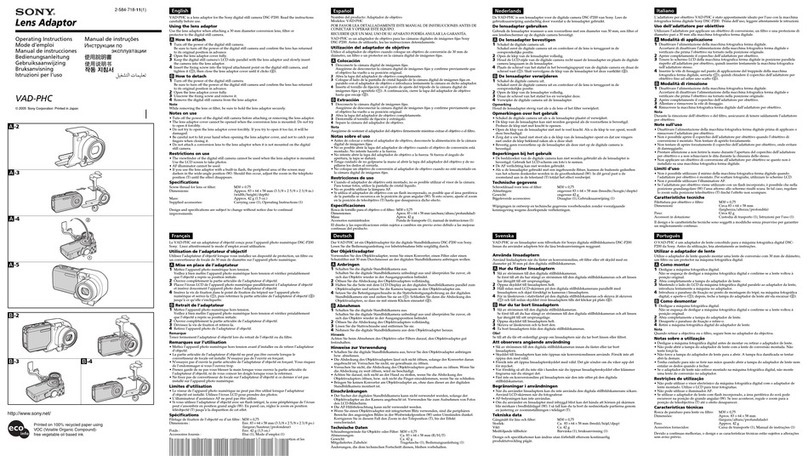

Sony VAD-PHC User manual

Sony

Sony DXF-51 User manual

Sony

Sony CBK-Z450UK User manual

Sony

Sony VF-30NKB User manual

Sony

Sony MPK-NA User manual

Sony

Sony HDTX100 User manual

Sony

Sony Electronic Viewfinder HDVF-C30W User manual

Sony

Sony SPK-HCG User manual

Sony

Sony BVF-V20W User manual

Sony

Sony CBK-3620XS User manual

Sony

Sony XC-777A User manual

Sony

Sony VCL-2030 S User manual

Sony

Sony SH-L32W User manual

Popular Camera Accessories manuals by other brands

Viltrox

Viltrox EF-NEX Mount instructions

Calumet

Calumet 7100 Series CK7114 operating instructions

Ropox

Ropox 4Single Series User manual and installation instructions

Cambo

Cambo Wide DS Digital Series Main operating instructions

Samsung

Samsung SHG-120 Specification sheet

Ryobi

Ryobi BPL-1820 Owner's operating manual