1

UP-DR200

Table of Contents

Manual Structure

Purpose of this manual ................................................................. 3

Related manuals ........................................................................... 3

1. Service Overview

1-1. Precaution when Transporting the Unit ..........................1-1

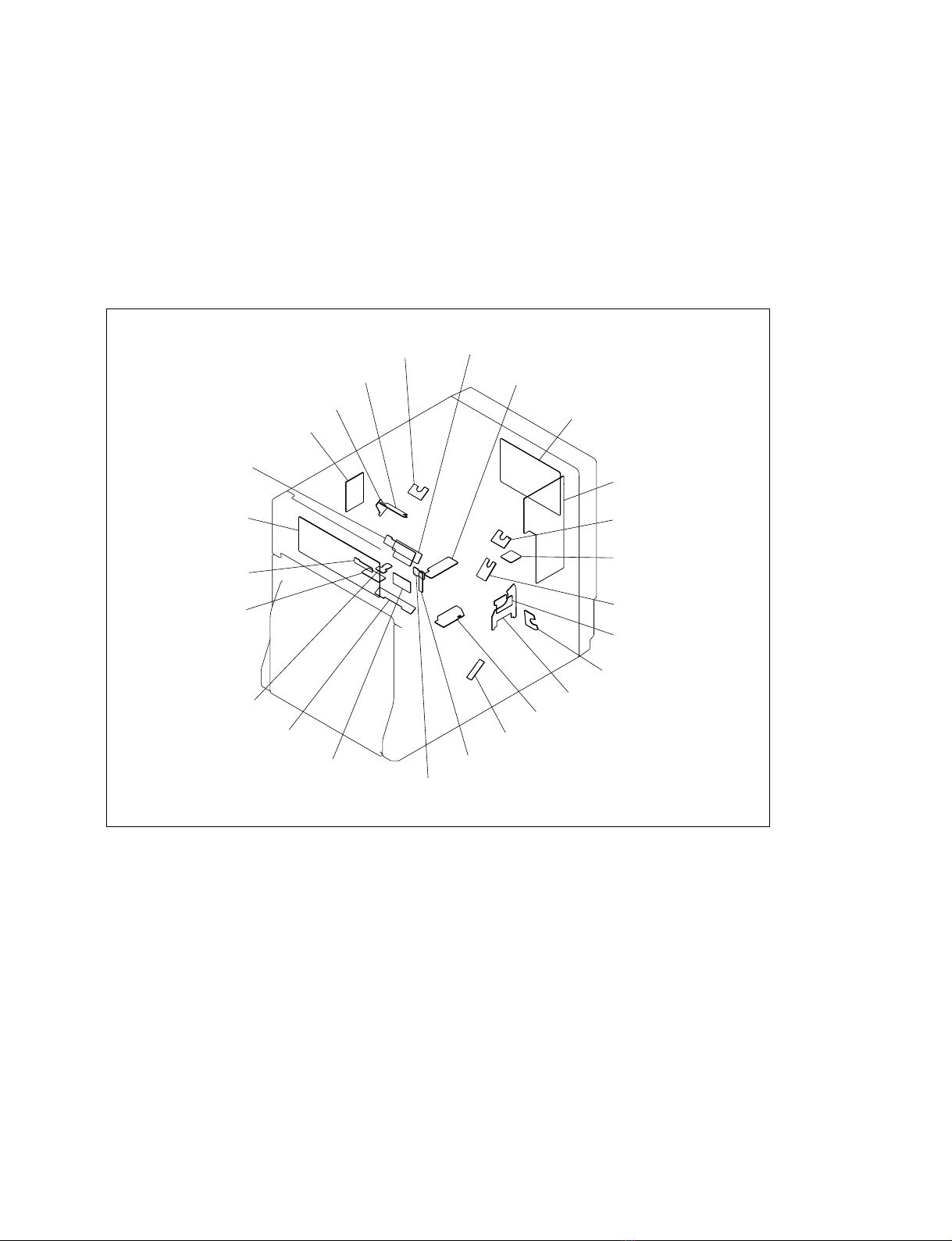

1-2. Board Location ...............................................................1-1

1-3. Main Parts and Sensor Location .....................................1-2

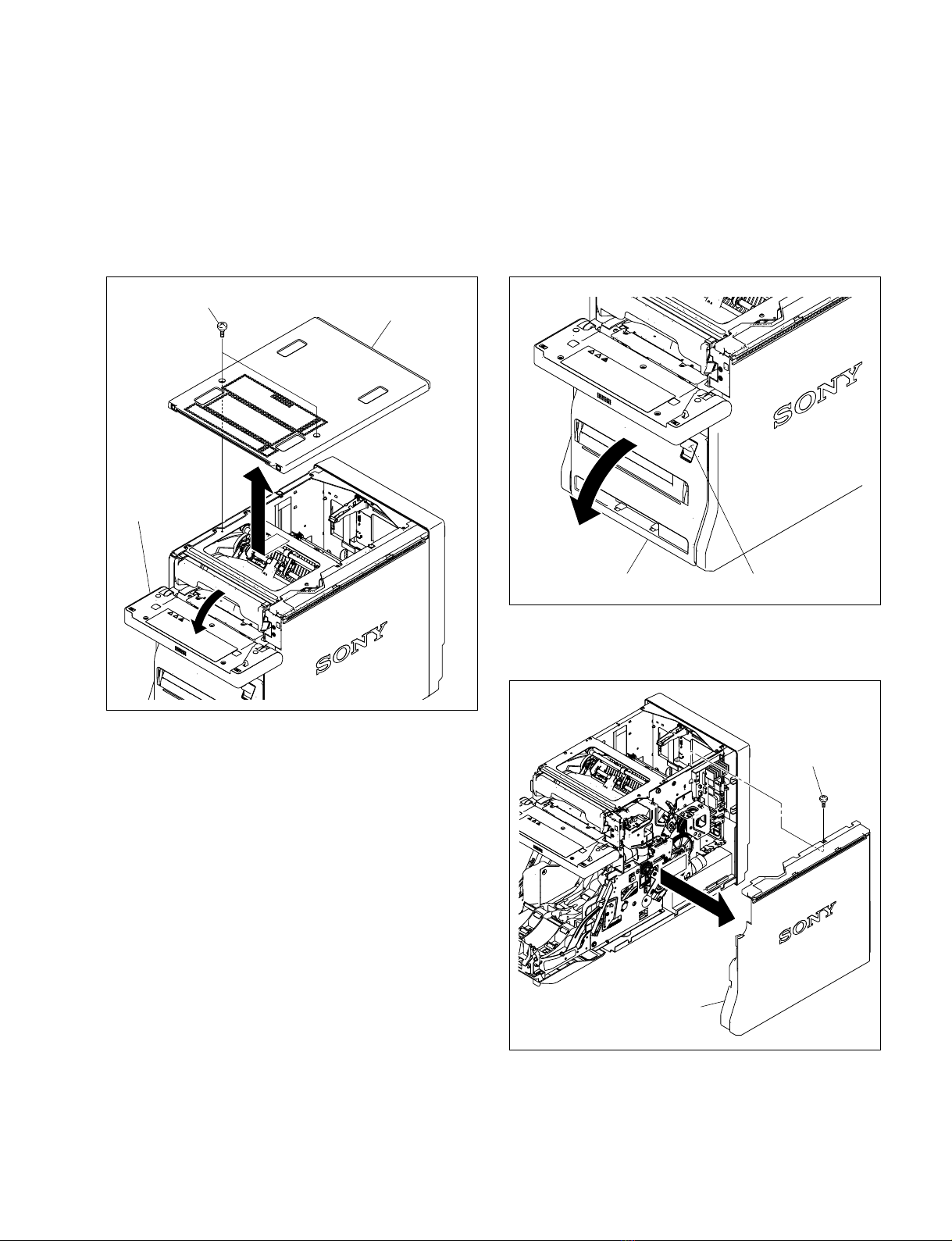

1-4. Removing/Installing the Cabinet ....................................1-3

1-4-1. Top Panel Assembly..............................................1-3

1-4-2.

Side Panel (R) Assembly/Side Panel (L) Assembly ...

1-3

1-4-3. Rear Panel Assembly ............................................1-4

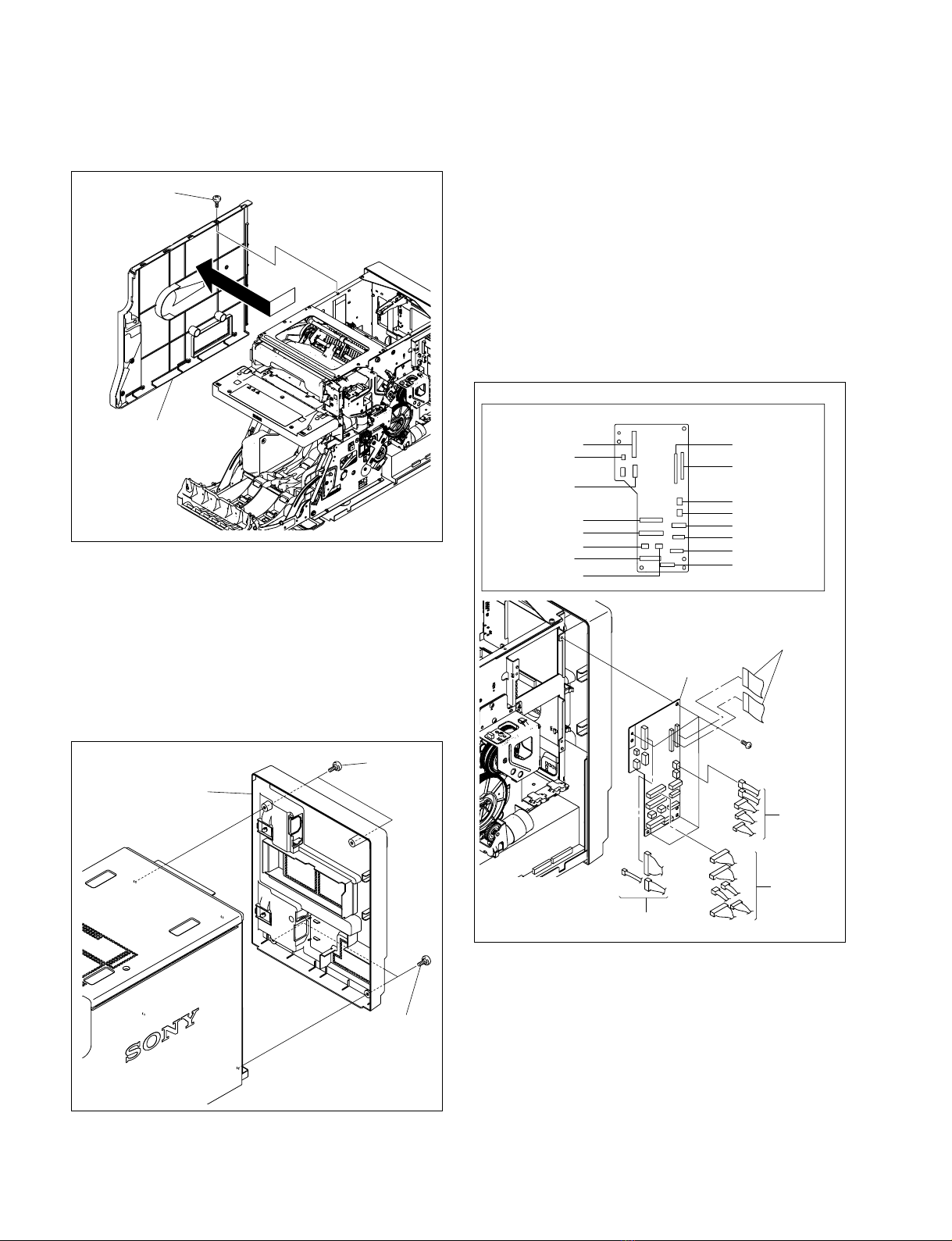

1-5. Replacing the Board .......................................................1-4

1-5-1. MEC-36 Board ......................................................1-4

1-5-2. MA-168 Board ......................................................1-5

1-5-3. KY-632 Board .......................................................1-5

1-5-4. SE-934 Board ........................................................1-6

1-6. Replacing the Main Parts................................................1-6

1-6-1. Ribbon Door Assembly .........................................1-6

1-6-2. Paper Door Assembly............................................1-7

1-6-3. Paper Holder (Main) Assembly.............................1-8

1-6-4. Ribbon Door Lock Assembly................................1-9

1-6-5. Cutter Unit.............................................................1-9

1-6-6. Pinch Motor Assembly ..........................................1-9

1-6-7. Supply Drive Assembly ......................................1-10

1-6-8. Takeup Drive Assembly......................................1-11

1-6-9. Paper Eject Guide Assembly ...............................1-12

1-6-10. Paper Holder Stay Assembly...............................1-12

1-6-11. Vertical Guide Assembly ....................................1-13

1-6-12. Return Guide Assembly ......................................1-15

1-6-13. Platen Roller ........................................................1-16

1-6-14. Capstan Roller .....................................................1-17

1-6-15. Pinch Roller .........................................................1-18

1-6-16. Stepping Motor....................................................1-19

1-6-17. Thermal Head ......................................................1-19

1-6-18. Head Unit Assembly ...........................................1-20

1-6-19. Pinch Cam/Head Cam .........................................1-21

1-6-20. Switching Regulator ............................................1-22

1-6-21. DC Fan (for inside) .............................................1-23

1-6-22. DC Fan (thermal head) ........................................1-23

1-6-23. Filter ....................................................................1-24

1-7. Cleaning the Interior .....................................................1-24

1-8. Recommended Power Cord ..........................................1-27

1-9. Unleaded Solder............................................................1-27

2. Adjustment for Parts Replacement

2-1. Thermal Head .................................................................2-1

2-1-1. Thermal Head Position Adjustment ......................2-2

2-2. Ribbon Mark Sensor (LE-352/SE-934 Board) ...............2-3

2-3. Paper FG Sensor (SE-935 Board)...................................2-3

2-4. MA-168 Board ................................................................2-4

3. Mechanical Operation Description

3-1. Mechanical Operation Flow ...........................................3-1

3-1-1. Power ON (or Door Open/Close)..........................3-1

3-1-2. Print Operation ......................................................3-2

3-2. Main Parts Constitution ..................................................3-3

3-3. Decurl Mechanism ..........................................................3-4

3-4. Ribbon Drive Mechanism...............................................3-5

3-5. Mechanical Operation.....................................................3-7

4. Circuit Description

4-1. Board Configuration .......................................................4-1

4-1-1. MA-168 Board ......................................................4-1

4-1-2. KY-632 Board .......................................................4-1

4-1-3. MEC-36 Board ......................................................4-1

4-2. Motor Control .................................................................4-1

4-2-1. Stepping Motor Driving ........................................4-1

4-2-2. Head Motor Driving ..............................................4-2

4-2-3. Pinch Motor Driving .............................................4-2

4-2-4. Takeup Motor Driving ..........................................4-2

4-2-5. Supply Motor Driving ...........................................4-2

4-2-6. Cutter Motor Driving ............................................4-2

4-3. Fan and Plunger Control .................................................4-2

4-3-1. Driving of Thermal Head Cooling Fan .................4-2

4-3-2. Driving of In-storage Cooling Fan ........................4-3

4-3-3. Plunger Driving .....................................................4-3

4-4. IC Tag Control ................................................................4-3

4-5. Sensor LED Control .......................................................4-3

4-5-1. Ribbon Mark Sensor LEDs ...................................4-3

4-5-2. Other Sensor LEDs................................................4-4

4-6. Sensor Detection .............................................................4-4

4-6-1. Pinch Home Sensor and Pinch Position Sensor ....4-4

4-6-2. Head Home Sensor and Head Position Sensor......4-4

4-6-3. Head arm Home Sensor and

Head Arm Position Sensor ....................................4-5