MVS-8000X/7000X

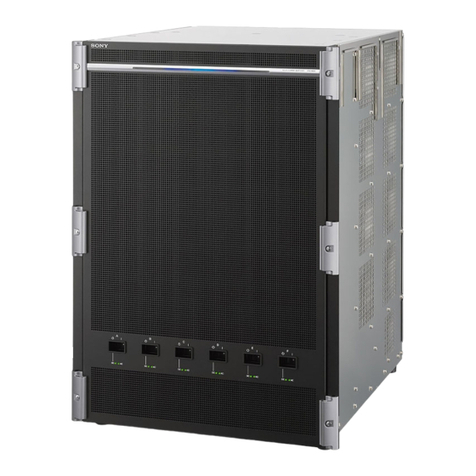

Attention-when the product is installed in Rack:

1. Prevention against overloading of branch circuit

When this product is installed in a rack and is supplied

power from an outlet on the rack, please make sure

that the rack does not overload the supply circuit.

2. Providing protective earth

When this product is installed in a rack and is supplied

power from an outlet on the rack, please confirm that

the outlet is provided with a suitable protective earth

connection.

3. Internal air ambient temperature of the rack

When this product is installed in a rack, please make

sure that the internal air ambient temperature of the

rack is within the specified limit of this product.

4. Prevention against achieving hazardous condition

due to uneven mechanical loading

When this product is installed in a rack, please make

sure that the rack does not achieve hazardous condi-

tion due to uneven mechanical loading.

5. Install the equipment while taking the operating

temperature of the equipment into consideration

For the operating temperature of the equipment, refer

to the specifications of the Operation Manual.

6. When performing the installation, keep the follow-

ing space away from walls in order to obtain

proper exhaust and radiation of heat.

Front, Right and Left: 10 cm (4 inches) or more.

c

.For safety, do not connect the connector for peripheral

device wiring that might have excessive voltage to the

following port(s).

: NETWORK A (CTRL) connector

: NETWORK B (DATA) connector

: NETWORK C*connector (MVS-8000X only)

: FM DATA connector

Follow the instructions for the above port(s).

.When you connect the NETWORK A (CTRL), NET-

WORK B (DATA), NETWORK C (MVS-8000X only),

and FM DATA connectors of the unit to peripheral

device, use a shielded-type cable to prevent malfunc-

tion due to radiation noise.

*Not supported.

For kundene I Norge

Dette utstyret kan kobles til et IT-strømfordelingssystem.

FORSIKTIG

For å redusere risikoen for støt, plugg inn strømtilfør-

selsledningene i hver sin kurs, med separat jording.

1 (P)