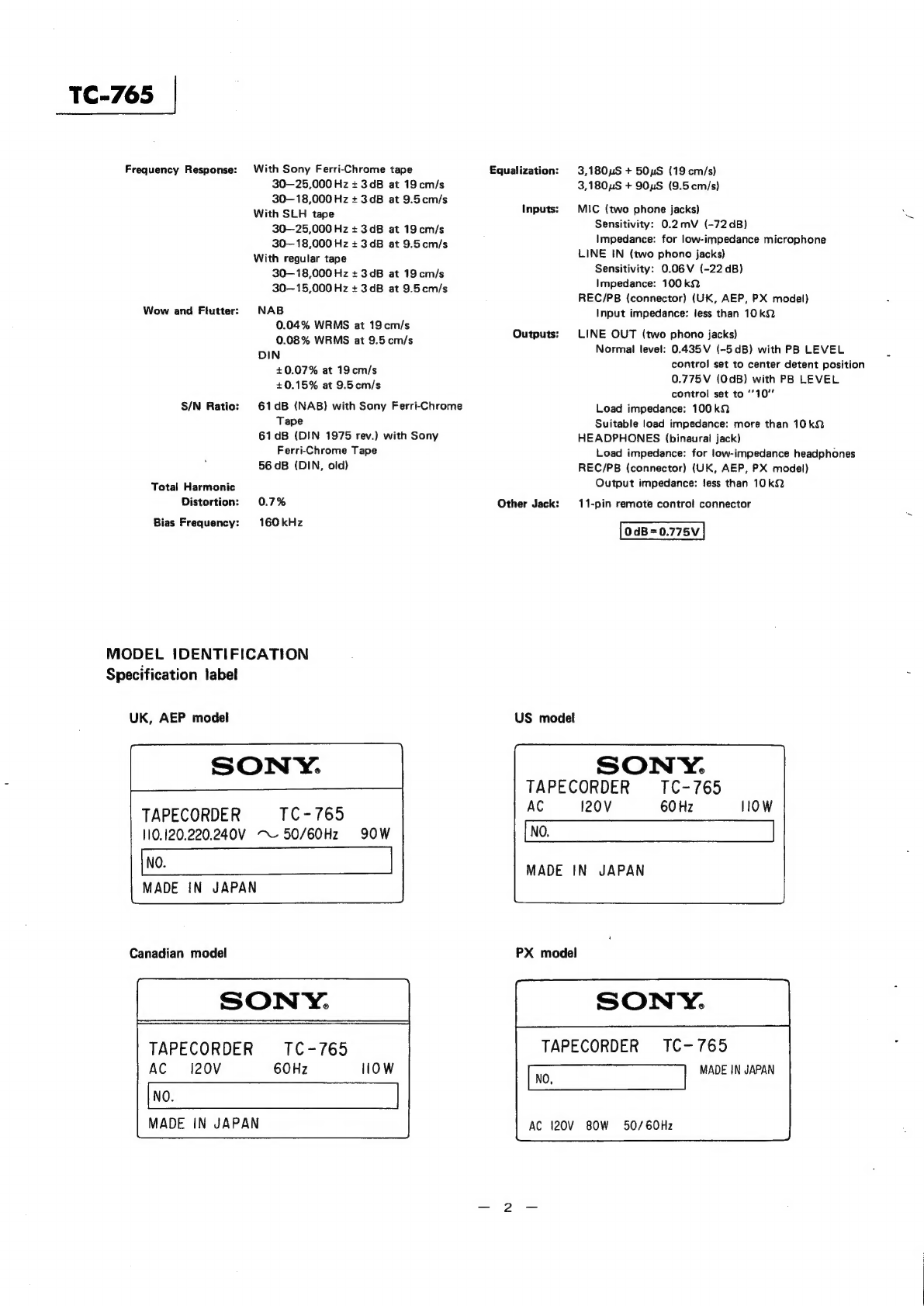

Sony TC-765 User manual

Other Sony Tape Deck manuals

Sony

Sony DTC-57ES User manual

Sony

Sony MDS-JA50ES / Mode d’emploi User manual

Sony

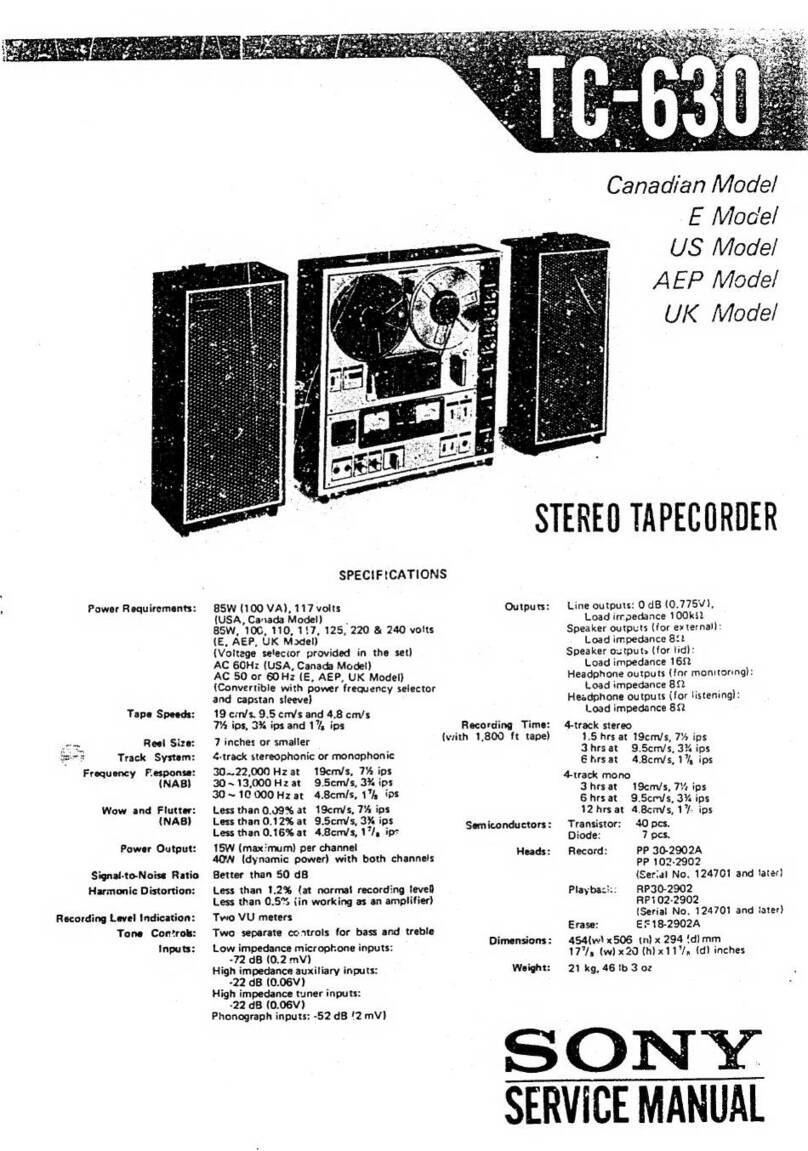

Sony TC-630 User manual

Sony

Sony TC-765 Setup guide

Sony

Sony PCM-R500 - Dat Recorder User manual

Sony

Sony DTC-A8 User manual

Sony

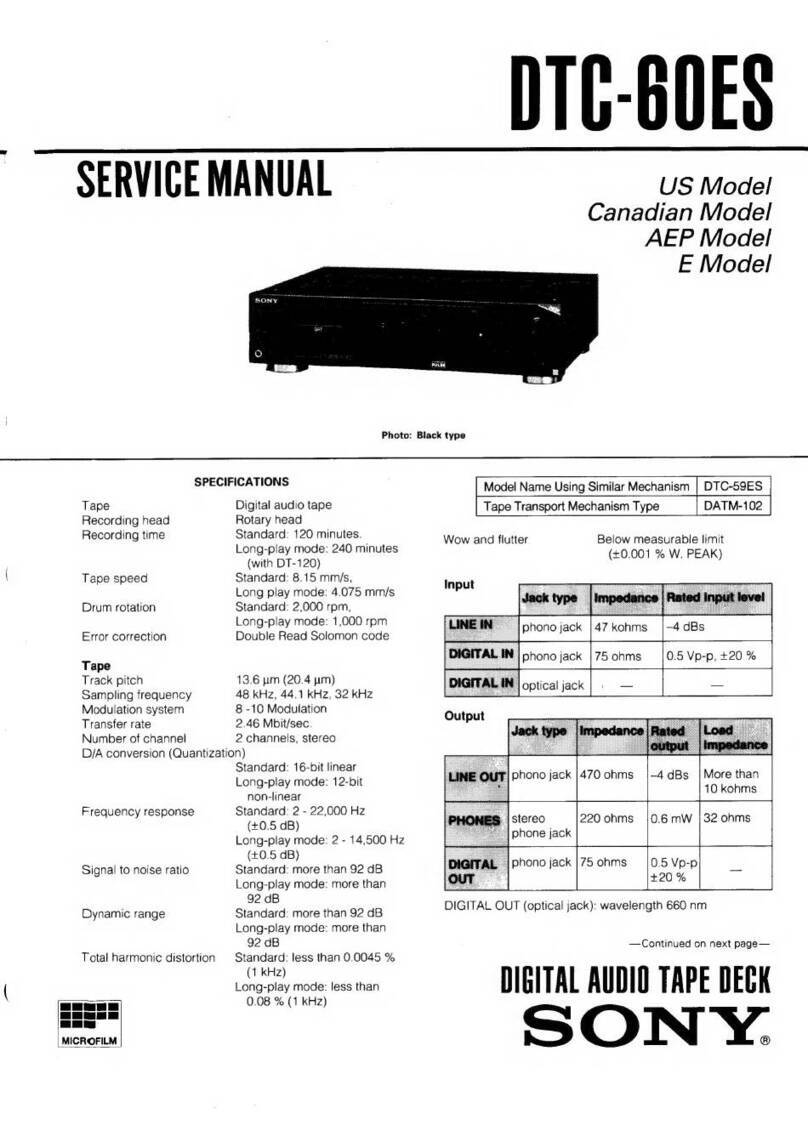

Sony DTC59ES User manual

Sony

Sony DTC-ZA5ES User manual

Sony

Sony DTC-1000 User manual

Sony

Sony DTC59ES User manual