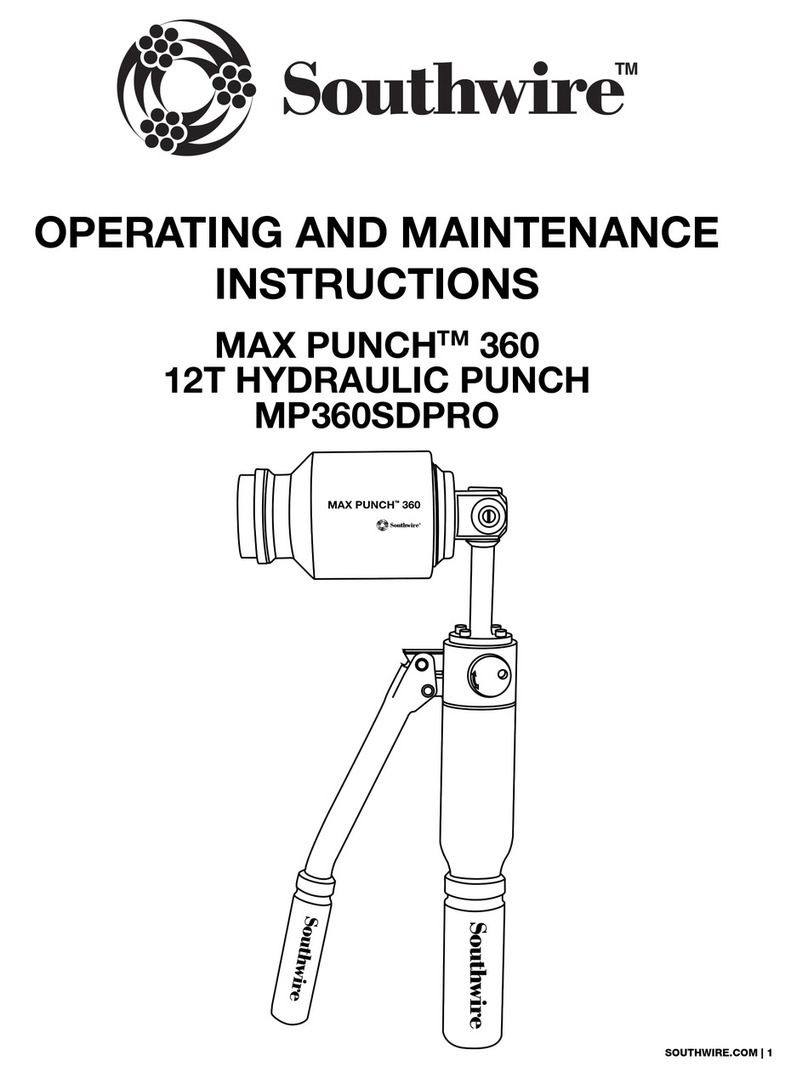

Southwire MAX PUNCH 360 Manual

OPERATING and MAINTENANCE

INSTRUCTIONS

MAX PUNCH

TM

360

12T HYDRAULIC PUNCH

(MP360SDPRO)

READ AND UNDERSTAND ALL

INSTRUCTIONS AND SAFETY INFORMATION IN

THIS MANUAL BEFORE OPERATING OR

SERVICING THIS TOOL

08/17

MP360SDPRO Manual

1

TABLE OF CONTENTS

Important Safety Information.................................................2 - 4

Description of Operation.............................................................5

Identification................................................................................5

Setup and Operation..............................................................6 - 7

Product Range Table................................................................. 6

Maintenance...............................................................................8

Warranty...............................................................................9 - 10

SAFETY FIRST

Safety is essential in the use and maintenance of Southwire

Contractor Equipment. This instruction manual and any markings

on the tool provide information for avoiding hazards and unsafe

practices related to the use of this tool. Observe all of the safety

information provided.

SAFETY ALERT SYMBOLS

These symbols are used to call attention to hazards or unsafe

practices related that could result in injury or property damage.

The three safety words defined below indicate the severity of the

hazard. The message after the signal word provides information

for preventing or avoiding the hazard.

2

DANGER:Electrical Shock Hazards.

• Only qualified persons should use MAX PUNCH™360 Hydraulic

Punch.

• Wear eye protection, hard hat, cut resistant gloves and safety

toe shoes when using this tool.

• Do not use tool while tired or under the influence of drugs,

alcohol, or medication.

• Keep body parts and loose clothing away from moving parts.

• Always follow safety procedures as shown in this manual.

• Keep hands clear of cup and cutter when in operation.

• Keep all body parts clear of handle’s path when not is storage

position.

• This is not an insulated tool, contact with live circuits could

result in severe injury or death.

FAILURE TO OBSERVE THESE WARNINGS CAN RESULT

IN SEVERE INJURY OR DEATH

Personal Safety Hazards

WARNING

• Read and understand all instructions and safety information in

this manual before operating or servicing this tool.

IMPORTANT SAFETY INFORMATION

FAILURE TO OBSERVE THESE WARNINGS COULD

RESULT IN SEVERE INJURY OR DEATH

WARNING:Tool Use Hazards

• Use this tool for the manufacturers intended purpose only.

Use other than that described in this manual can result in injury

or property damage.

• Inspect all aspects of the electrical box to ensure safety.

• Only qualified personnel should use knockout equipment.

• Keep all decals clean and legible, and replace when necessary.

CAUTION:

• Read and understand all of the instructions and safety information

in this manual before operating or servicing this tool.

CAUTION:

• Do not use if the cutters are damaged as this can cause binding

leading to tool malfunction.

• If tool is in disrepair, DO NOT USE. Have tool serviced at an

Authorized Southwire Repair Center

Make sure bystanders are clear of the work area when performing

knockouts. Nearby personnel can be injured if there is flying debris.

FAILURE TO OBSERVE THESE CAUTIONS CAN RESULT IN

INJURY OR PROPERTY DAMAGE

FAILURE TO OBSERVE THESE CAUTIONS CAN RESULT IN

INJURY OR PROPERTY DAMAGE

IMPORTANT SAFETY INFORMATION

WARNING:Entanglement Hazard

• Do not operate this tool while wearing loose fitting clothing.

Retain long hair.

• Keep hands away from cup and cutters while operating punch.

Could pinch or crush hands.

• Do not add extensions (cheaters) to the handles. Using

excessive force may result in injury or damage to the tool.

If excessive force is required, check and verify proper set up

instructions.

FAILURE TO OBSERVE THESE WARNINGS CAN RESULT

IN SEVERE INJURY OR DEATH.

34

WARNING:

FAILURE TO OBSERVE THESE WARNINGS CAN RESULT

IN SEVERE INJURY OR DEATH

FAILURE TO OBSERVE THESE WARNINGS CAN RESULT

IN SEVERE INJURY OR DEATH

5

DESCRIPTION OF OPERATION

This manual is intended to familiarize all personnel with the safe

operation and maintenance procedures for the following Southwire

Tools and Equipment: MAX PUNCH™360 HYDRAULIC PUNCH.

Keep this manual available to all personnel. Replacement manuals

are available upon request at no charge at

www.southwiretools.com.

PURPOSE OF THIS MANUAL

The MAX PUNCH™ 360 Hydraulic Punch is a tool that will knockout

½” – 4” diameter holes in mild steel and stainless steel electrical

panels.

6

IDENTIFICATION

PRODUCT RANGE TABLE

SET UP AND OPERATION

1. Draw Stud Input

2. 360 Degree Articulation Head

3. Hydraulic Pressure Valve

4. Hydraulic Cylinder

5. Pump Handle

6. Die Cutter

6. Die Cup

8. ¾” Draw Stud

9. 7/16” Draw Stud

10. ½” Spacer

11. Marksman® Layout Tool

12. Step Bit

1. Use a step bit to drill the pilot holes (Fig. 1).

2. Make sure that the hydraulic pressure valve is in the off position.

3. Screw the draw stud into the articulation head.

NOTE: For ½” punch use 7/16” draw stud, for ¾”-2” punch use

the ¾” draw stud, and for 2-1/2”-4” punch use 1-1/8” draw

stud (Fig. 2).

4. Insert cup onto draw stud facing panel (Fig. 3).

5. Insert draw stud through pilot hole (Fig. 4).

6. Screw on cutter (Fig. 5).

7. Make sure that all three cutter points on the cutter are tight

to the panel.

8. Close pressure valve by turning clockwise to the “ON” position

(Fig. 6).

9. Position the articulation head to a comfortable position.

10. Begin operating the pump handle, stop compressing when

knockout is complete (Fig. 7).

11. Release pressure valve by turning counter clockwise to the

“OFF” position.

12. Unscrew cutter die to release slug (Fig. 8).

MP360SDPRO/MP-03PRO Stainless Steel Knockout

ADDITIONAL HELP

SPECIFICATIONS

• There is a ½” spacer available for convenience but is not

necessary to complete knockout.

• Do not rotate articulating head during the pumping process.

• Release pressure in the hydraulic system when not in use.

MAINTENANCE

Maintain appropriate hydraulic fluid capacity by adding or

changing hydraulic fluid as needed for proper pressure.

Too much hydraulic fluid will cause the MP360HP to

not work properly and may lead to personal injury.

SERVICING

1. Unscrew the hydraulic cylinder.

2. Pinch bladder end with one hand while pulling out the plug

with a pair of pliers.

3. Add hydraulic fluid; leave ½”-1” of space between the

hydraulic fluid level and the end of the bladder.

4. Replace plug.

5. Replace hydraulic cylinder.

Fig. 1 Fig. 2

Fig. 3 Fig. 4

Fig. 5 Fig. 6

Fig. 7 Fig. 8

MODEL # STOCK # DESCRIPTION LENGTH WIDTH DEPTH WEIGHT

MP360SDPRO 58-97-38-01

MAX PUNCH™ 360 Stainless Steel 1/2"-2" Set

21"12" 4" 15lbs

MP-03PRO 57-17-72-01

Large Die Set for Stainless Steel (2-1/2"-4")

In Case (Drive Unit Not Included)

16.5" 13" 4" 24lbs

MP360HP 58-94-63-01 MAX PUNCH™ 360 (Drive Unit Only) 1.5" 5.25" 3.75" 5.5lbs

WARNING:

CAUTION:

7 8

10

Warranty Claim Information/How Do You Get Service?

For all warranty, customer service, and product return authorizations and inquiries,

please contact Southwire’s Tools & Assembled Products at:

Southwire Tools & Assembled Products

840 Old Bremen Road

Carrollton, GA, 30117

Phone Number: 1.855.SW.Tools

Repair Your Product When it is Out of Warranty

Southwire is happy to provide information about where a purchaser can send a product for

repair at consumers’ own expense, please contact 1.855.SW.tools or visit

www.southwiretools.com/tools/home.do for more information about servicing for Southwire

Products.

WARRANTY ON

SOUTHWIRE CONTRACTOR EQUIPMENT

What Does This Warranty Cover?

Five-Year Limited Warranty on Contractor Equipment

Under Southwire’s Contractor Equipment 5-Year Limited Warranty, Southwire Company, LLC

warrants that all Southwire Contractor Equipment will be free from manufacturer defects for a

period of five (5) years from the date of the original end user’s purchase. However, electrical

components and consumable parts such as ropes, blades, dies, draw studs, grips, are

excluded from this 5-Year Limited Warranty and are subject to the One -Year warranty terms.

Under this 5-Year Limited Warranty, the following are also excluded and Southwire

Company, LLC will have no liability for any of the following: normal wear and tear resulting

from product use and damage arising out of misuse, abuse, modification, and improper

product maintenance. This warranty also does not cover Southwire Contractor Equipment

products that have been modified by any party other than Southwire Company, LLC or its

authorized third party designee. This 5-Year Limited Warranty is not transferrable to or

enforceable by any person other than the product’s original end user.

One-Year Limited Warranty on Electrical Components and Consumable

Parts (with 5-Year warranty)

Under Southwire’s 1-Year Limited Warranty, Southwire Company, LLC warrants that all

electrical components and consumable parts such as ropes, blades, dies, draw studs, grips

will be free from manufacturer defects for a period of one-year from the date of the original

end user’s purchase. Under this 1-Year Limited Warranty, Southwire Company, LLC will have

no liability for any of the following: normal wear and tear resulting from product use and

damage arising out of misuse, abuse, modification, and improper product maintenance. This

warranty also does not cover Southwire electrical components and consumable parts that

have been modified by any party other than Southwire Company, LLC or its authorized third

party designee. This 1-Year Limited Warranty is not transferrable to or enforceable by any

person other than the product’s original end user.

Exclusion of Incidental, Consequential, Indirect, Special and Punitive Damages

SOUTHWIRE MAKES NO WARRANTY THAT SOUTHWIRE CONTRACTOR EQUIPMENT PROD-

UCTS WILL BE MERCHANTABLE OR FIT FOR ANY PARTICULAR PURPOSE. SOUTHWIRE MAKES

NO OTHER WARRANTY, EXPRESSED OR IMPLIED, OTHER THAN THE RELEVANT WARRANTY

SPECIFICALLY SET FORTH IN THIS WARRANTY SECTION. SOUTHWIRE WILL NOT BE LIABLE

FOR ANY INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, OR PUNITIVE DAMAGES FOR

ANY BREACH OF THIS LIMITED LIFETIME WARRANTY.

Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

9

1. All warranty claims must be approved by Southwire’s Tools & Assembled Products

Warranty Department prior to return of product. If Southwire determines that a product is

defective, Southwire will, at its option, repair or replace defective products or defective

product components, free of charge.

2. Upon approval, Southwire will issue a Product Return Authorization Form which will

include instructions on how and where to return the product. The product serial number

and the original date of delivery must be set forth on the Product Return Authorization

Form.

3. Southwire will cover standard freight charges (Ground Courier Rate) incurred in connection

with products that Southwire ultimately determines to be defective.

4. All defective components and defective products that Southwire replaces under these

Warranties will become Southwire’s property and will be retained by Southwire.

Other manuals for MAX PUNCH 360

1

This manual suits for next models

2

Table of contents

Other Southwire Tools manuals

Southwire

Southwire Shoreline Reels RW User manual

Southwire

Southwire HB1A-9 Series User manual

Southwire

Southwire XTS-01 User manual

Southwire

Southwire MAX PUNCH XD Manual

Southwire

Southwire MSP-01 Manual

Southwire

Southwire Triggers TSS-01 User manual

Southwire

Southwire MAX PUNCH 360 Manual

Southwire

Southwire RR-SW45 User manual