TABLE OF CONTENTS

1. Preface·······································································3

1.1 Important···························································3

1.2 How To Use This Manual ···································3

2. Safety·········································································3

2.1 General Safety Informaon ·······························3

2.2 Unpacking The System·······································4

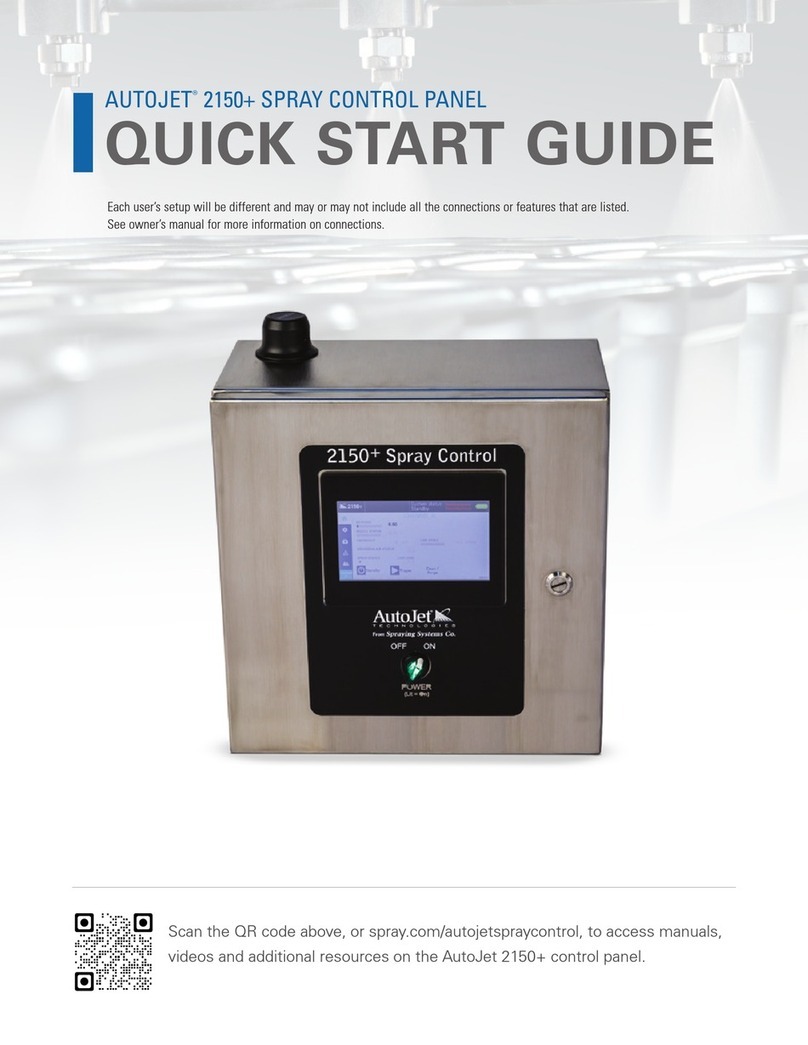

3. 2150+ Overview·························································5

3.1 System Features·················································5

3.2 System Specicaons·········································5

3.3 Precision Spray Control (PSC)·····························6

3.4 Posion Or Mount The System··························7

3.5 Plug And Spray Connecons ······························7

3.6 Remote Connecon ···········································8

3.7 Screen Buons And Icons ··································8

3.8 HMI Operaons—Set Spray Parameters ···········9

3.9 Recipes·······························································9

4. 2150+ Home Screen·················································10

4.1 Home Screen—Channel A and B······················10

4.2 Home Screen Opons ······································11

4.3 Purge And Clean···············································12

5. General Sengs·······················································13

5.1 Sengs Screen·················································13

5.2 User Management Sengs······························14

5.3 User Groups ·····················································16

6. Supplying Air To The System····································17

6.1 Adjustments and Operaons···························17

7. Applicaon Sengs ·················································18

7.1 Spray Nozzle Sengs·······································18

7.2 Spray Timing Modes·········································22

7.3 Fixed Spray Time··············································22

7.4 Variable Spray Time ·········································25

7.5 Conguraon ···················································29

7.6 Recipe Sengs·················································31

7.7 Duty Cycle ························································33

7.8 Trigger······························································35

7.9 Tank Level Sensor·············································36

8. Pressure Sensor (Opon)·········································37

8.1 Liquid Pressure (Pressure Sensor)····················37

8.2 Pressure Sensor Spare Parts ····························38

9. Speed/Encoder (Opon)···········································39

9.1 Speed/Encoder··················································39

9.2 Encoder Selecon·············································· 40

9.3 Encoder Spare Parts·········································· 41

10. Flow Meter (Opon)···············································42

10.1 Flow Meter Sengs ········································ 42

10.2 Assembly Specicaons··································43

10.3 Flow Meter Spare Parts···································44

11. Faults And Alarms··················································· 44

11.1 Faults And Alarms Sengs······························44

12. Maintenance And Troubleshoong························45

12.1 Maintenance And Troubleshoong Sengs··· 45

13. Diagnoscs······························································ 47

14. Trigger Devices And Accessories····························· 47

14.1 Electric Nozzle Cord Set ··································47

14.2 Trigger Cable ··················································· 48

14.3 Photoelectric Object Sensor····························48

14.4 Color Sensor····················································49

14.5 Proximity Sensor ············································· 49

14.6 Trigger Interlock··············································49

14.7 Foot Switch······················································49

14.8 Hand Trigger Pendant ····································· 50

14.9 Thru-Beam Sensor··········································· 50

14.10 Laser Sensor (Short)·······································51

14.11 Laser Sensor (Long)········································51

14.12 Fault Output Signal ········································51

14.13 Fault Output cable Kit····································52

14.14 Extension Cable··············································53

14.15 Input Signal ···················································· 53

14.16 Level Sensor Input·········································· 54

14.17 Trigger Devices Overview·······························54

15. Faults And Troubleshoong····································55

15.1 Internal Components ······································58

16. Ethernet IP Manual (Oponal)································59

16.1 Studio 5000 Import Example···························59

16.2 Loading the Registered EDS File ·····················61

16.3 Ethernet IP Address List: Read Address··········63

16.4 Ethernet IP Address List: Write Address·········64

16.5 BIT Numbers, Faults, and Their Descripons·· 65

17. Spare And Replacement Parts ································ 66