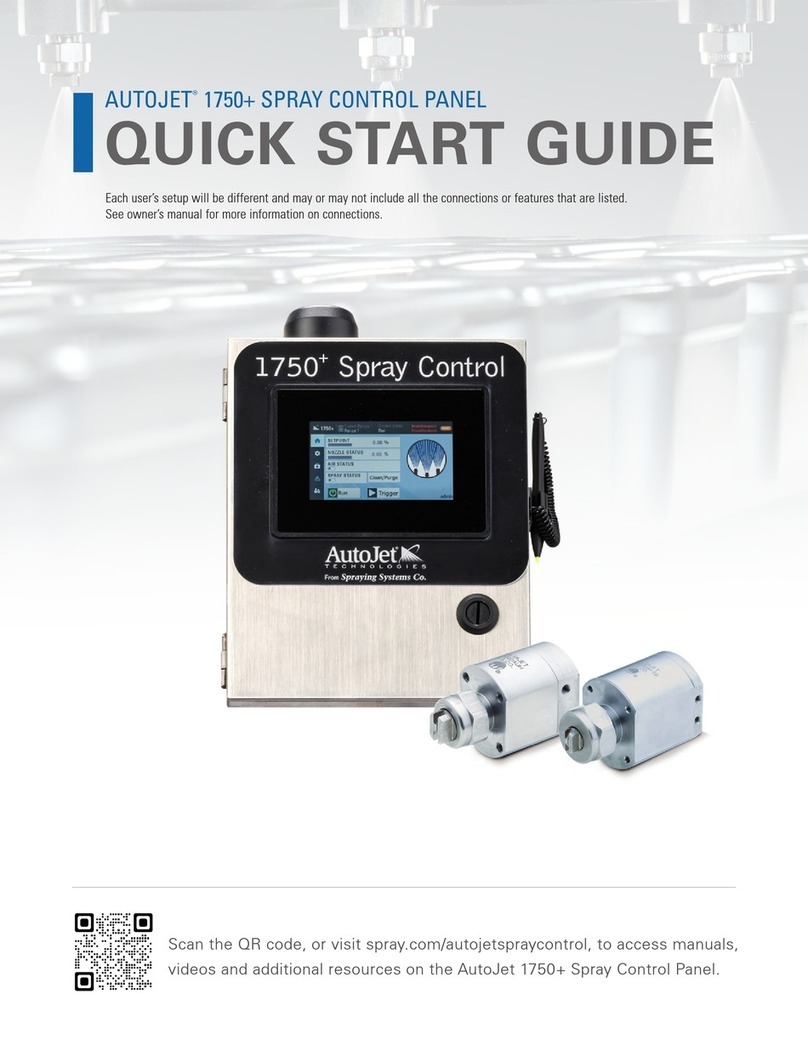

Flow meter panel,

dual-channel version

3.

ADDITIONAL CONNECTIONS

IF APPLICABLE

Main 1

[4A Max.]

Main 2

[4A Max.]

Trig T. Int.

Remote

Setpoint Level Pressure Encoder Flow

Fan/Atm

Air

132

4 65 7 8

1. TRIGGER OR SENSOR

Connect cable to Trig connection that will be

used to start spray sequence. Available triggers

are as follows, the one used should be based

on the customer’s application.

•Trigger cable (for use with customer-supplied

trigger signal)

•Sensors including:

– Object

– Proximity

– Laser (short/long)

– Thru-beam

– Full spectrum color sensor

•Hand-held trigger unit

•Foot switch

2. FAN/ATOMIZING AIR

The Fan/Atm Air electrical connection is used to

actuate the air solenoids in our air control panel.

Connect the cable from the air control panel to

Fan/Atm Air connection on the panel.

3. TRIGGER INTERLOCK

Trigger Interlock controls the state of run/standby

mode. Connect the trigger interlock cable to the T. Int.

connection on the panel.

4. REMOTE SETPOINT (DUTY CYCLE)

Connect the Remote Setpoint cable to the panel.

Once the unit is powered up on the HMI you can set

the duty cycle with a 4-20mA signal to control the

spray nozzles cycle speed.

5. TANK LEVEL SENSOR

Connect the level sensor cable to the Level connec-

tion on the panel. Activate the level sensor from the

Level settings screen on the HMI once the unit is

powered on. When the tank level gets low enough to

trigger the sensor, the unit will display a fault (tank

low) on the screen. Note that the system will not stop

spraying, only show a fault to warn

the operator.

6. LIQUID PRESSURE

Liquid pressure settings require an

active pressure sensor connection

to the 2150+. Connect the pressure

cable to the Pressure connection.

When connected, the input settings

should be calibrated to match the

specifications of your pressure sensor.

7. ENCODER

Encoders are used to read the

speed of a conveyor or machine

shaft. Install the encoder, then

connect the cable to the Encoder

connection on the panel. Activate

the encoder from the HMI in the

Encoder settings screen.

8. FLOW METER

Our Flow Meter Panel will display

flow readings on the HMI. Install the

panel then connect the cable from

the Flow Meter to the Flow connec-

tion on the panel. Set input values to

match the specifications of the flow

meter on the HMI once

it is powered on.

Standard pressure

sensor

Flush-style

pressure sensor

Wheel and pivot

mounted encoder

Hollow shaft

encoder