Y05/YL5 INSTALLATION INSTRUCTIONS

General Description: This application should be installed and used as recommended by the National Fire Protection

Association standards and practices.

The Installer should be familiar with these requirements together with any local codes or special requirements of the local

Fire Authority having jurisdiction.

The alarm sounders are intended for connection to the output alarm circuit of a UL listed fire alarm control panel only. All

alarms are compatible with DC line status monitoring. The alarm sounders are suitable for outdoor use (-35ºC to +66ºC).

Installation procedures must confirm to appropriate agency requirements including but not limited to the following:-

NFPA72E, NEC ART.760 ET.AL., CAN/ULC-S524-M86, CEC PART 1 SEC 32

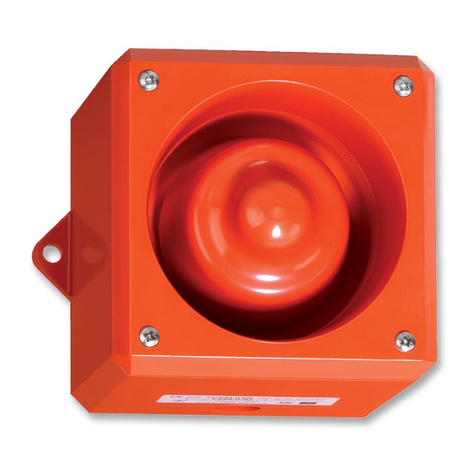

Installation: The sounder can be affixed to most surfaces using screws through the external mounting lugs or by drilling

internal fixing holes. A 20mm gland entry is provided for the supply cable. The cable and gland must be fitted in accordance

with the national and local regulations. It is not necessary to earth the sounder circuitry but earth tags should be used if earth

continuity of conduit or cable sheathing needs to be maintained.

Supply input: Ensure that the supply is correct for the voltage rating of the sounder or combined sounder strobe being

installed. Ensure the supply is OFF before making any connection and wire only in accordance with the terminal label detail.

Sound selection: Ensure the supply is OFF before proceeding. All dc and ac units have selectable alarm sounds (see table

below for details) and are selectable by means of a 5 way dil switch SW1. A second sound is made available upon the

application of a third wire connected to terminal TB1/3 as shown in Fig. 1 while still connected to terminal TB1/2. Alternatively

1st and 2nd stage sound signals can be generated by supply reversal (FOR DC UNITS ONLY) see Fig. 2. Independent

second stage sound is available by using SW2 (OPTIONAL- only fitted with orders).

WARNING - Loud alarm sound. Wear ear defenders when testing, installing and commissioning.

SOUND SELECTION TABLE

First Stage Sound frequency rept. Second switches

Hertz rate Stage 1 2 3 4 5 Special Application

1 Alternate two-tone 800-1000 0.5 3 1 1 1 1 1 Fire Alarms

2 Alternate two-tone 2500-3100 0.5 4 0 1 1 1 1 Security Alarms

3 Alternate fast two-tone 800-1000 0.25 7 1 0 1 1 1 Increased urgency

4 Alternate fast two-tone 2500-3100 0.25 8 0 0 1 1 1 Security deterrent

5 Alternate two-tone 440-554 0.4/0.1 14 1 1 0 1 1 AFNOR, France

6 Alternate two-tone 430-470 1.0 14 0 1 0 1 1

7 Alternate v.fast two-tone 800-1000 0.13 12 1 0 0 1 1

8 Alternate v.fast two-tone 2500-3200 0.07 13 0 0 0 1 1

9 Alternate two-tone 440-554 2.0 10 1 1 1 0 1 Turn-out, Sweden

10 Continuous note 700 - 1 0 1 1 0 1 All-clear, Sweden

11 Continuous note 1000 - 31 1 0 1 0 1

12 Continuous note 1000 - 7 0 0 1 0 1

13 Continuous note 2300 - 2 1 1 0 0 1

14 Continuous note 440 - 9 0 1 0 0 1

15 Interrupted tone 1000 2.0 31 1 0 0 0 1

16 Interrupted tone 420 1.25 30 0 0 0 0 1 AS2220, Australia

17 Interrupted tone 1000 0.5 1 1 1 1 1 0

18 Interrupted tone 2500 0.25 4 0 1 1 1 0

19 Interrupted tone 2500 0.5 2 1 0 1 1 0

20 Interrupted tone 700 6/12 10 0 0 1 1 0 Pre-vital mess, Sweden

21 Interrupted tone 1000 1.0 32 1 1 0 1 0

22 Interrupted tone 700 4.0 10 0 1 0 1 0 Air-raid, Sweden

23 Interrupted tone 700 0.25 10 1 0 0 1 0 Local warning, Sweden

24 Interrupted tone 720 0.7/0.3 10 0 0 0 1 0 Industrial alarm, Germany

25 Int,fast,rising volume 1400 0.25 26 1 1 1 0 0

26 Fast siren 250-1200 0.085 11 0 1 1 0 0

27 Rising constant, fall 1000 10/40/10 17 1 0 1 0 0 Industrial alarm, Germany

28 ISO 8201 Evacuation 800-1000 as std 11 0 0 1 0 0 Int’l evacuation alarm

29 Fast whoop 500-1000 0.15 32 1 1 0 0 0

30 Slow whoop 500-1200 4.5 12 0 1 0 0 0 Evacuation, The Netherlands

31 Reverse sweep 1200-500 1 11 1 0 0 0 0 Evacuation, Germany

32 Siren 500-1200 3.0 26 0 0 0 0 0

switch settings: ON=1 and OFF=0

MOUNTING: The Y05 series alarm units are mounted to a wall or bulkhead of suitable material using the lugs projecting from the

side of the case. The lugs are bored 8mm clearance on 153mm centres. The recommended length of fixing screws is 25mm. To

maintain the integrity of the weather seal, the cable entry must be via a suitable sealed gland.

D7426/4