6947300000

17

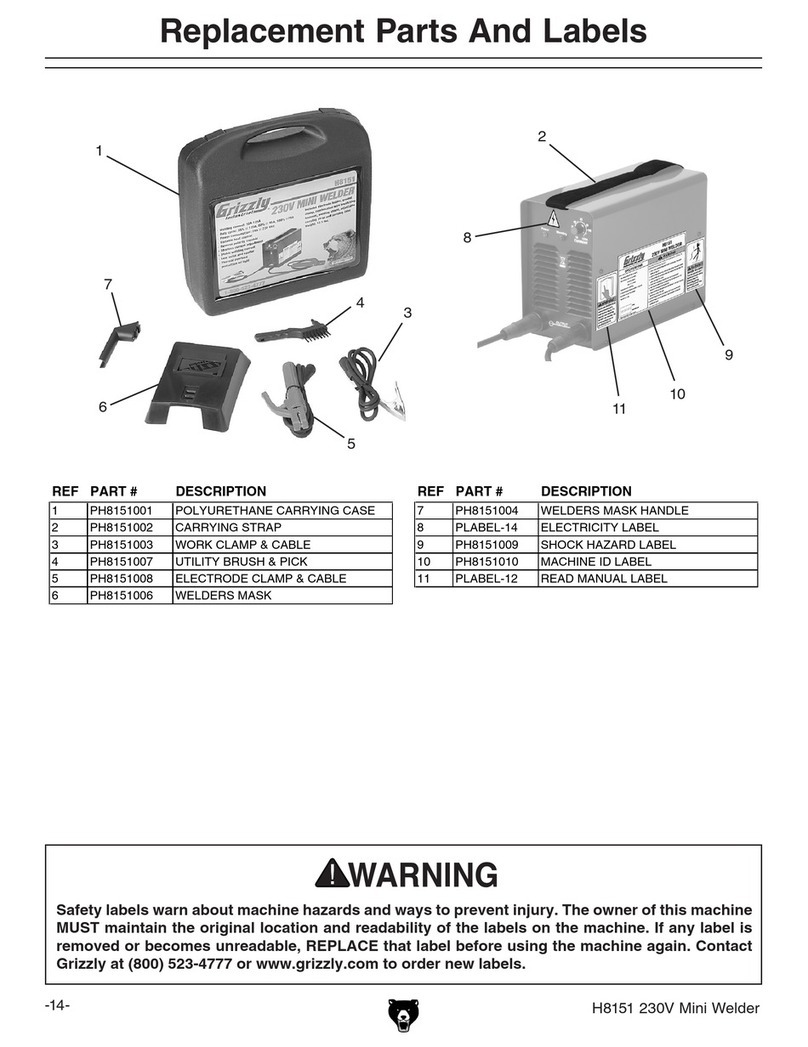

PREPARING FOR

ELECTRODE WELDING

1) Respect the indications given previously

concerning primary connection and installation.

2) Connect the earth cable to the socket of the

machine. Negative polarity ( - )

3) Connect the electrode holder to the socket of

the machine. Positive polarity ( + );

4) Insert the bare core of the electrode in the gun;

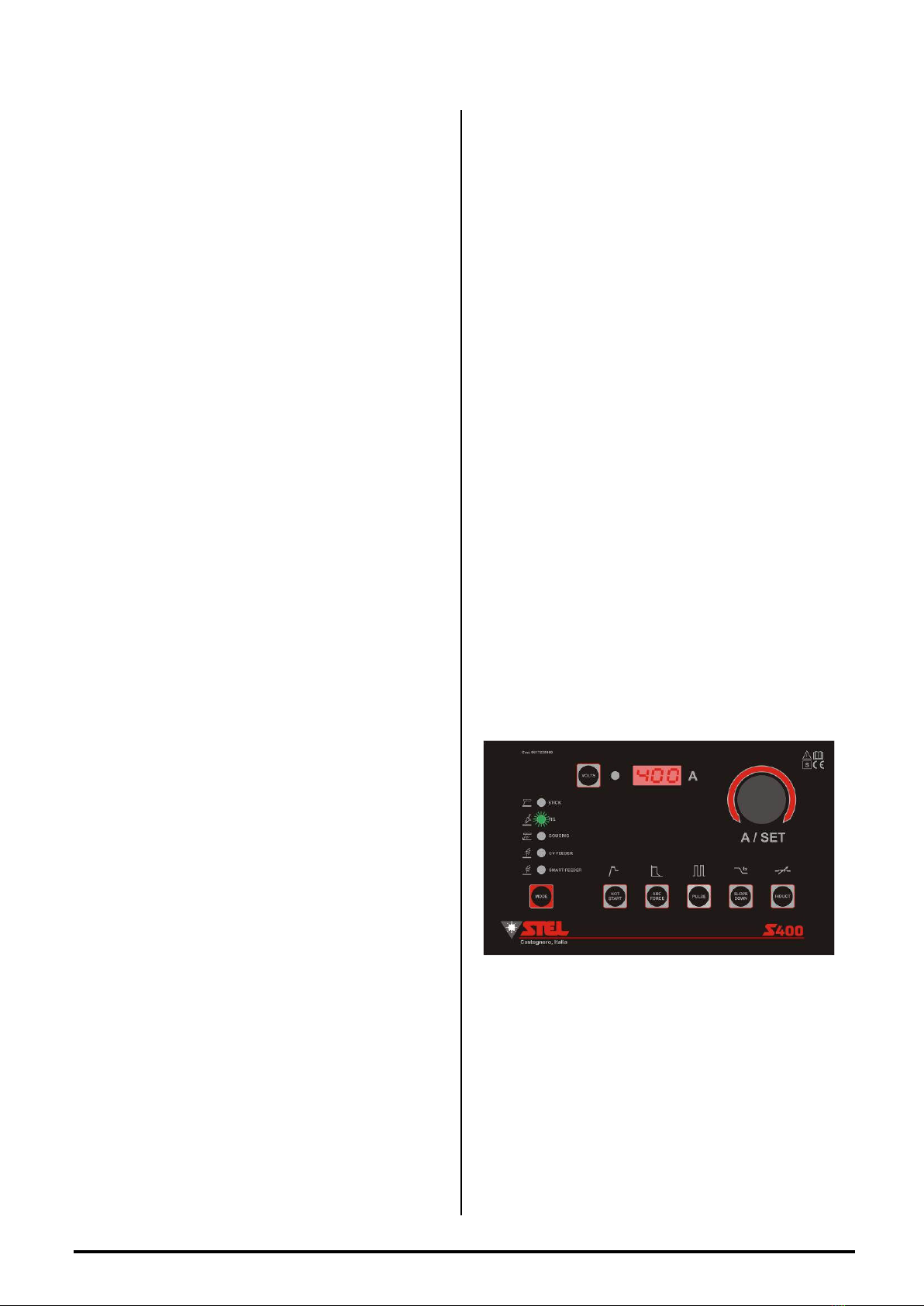

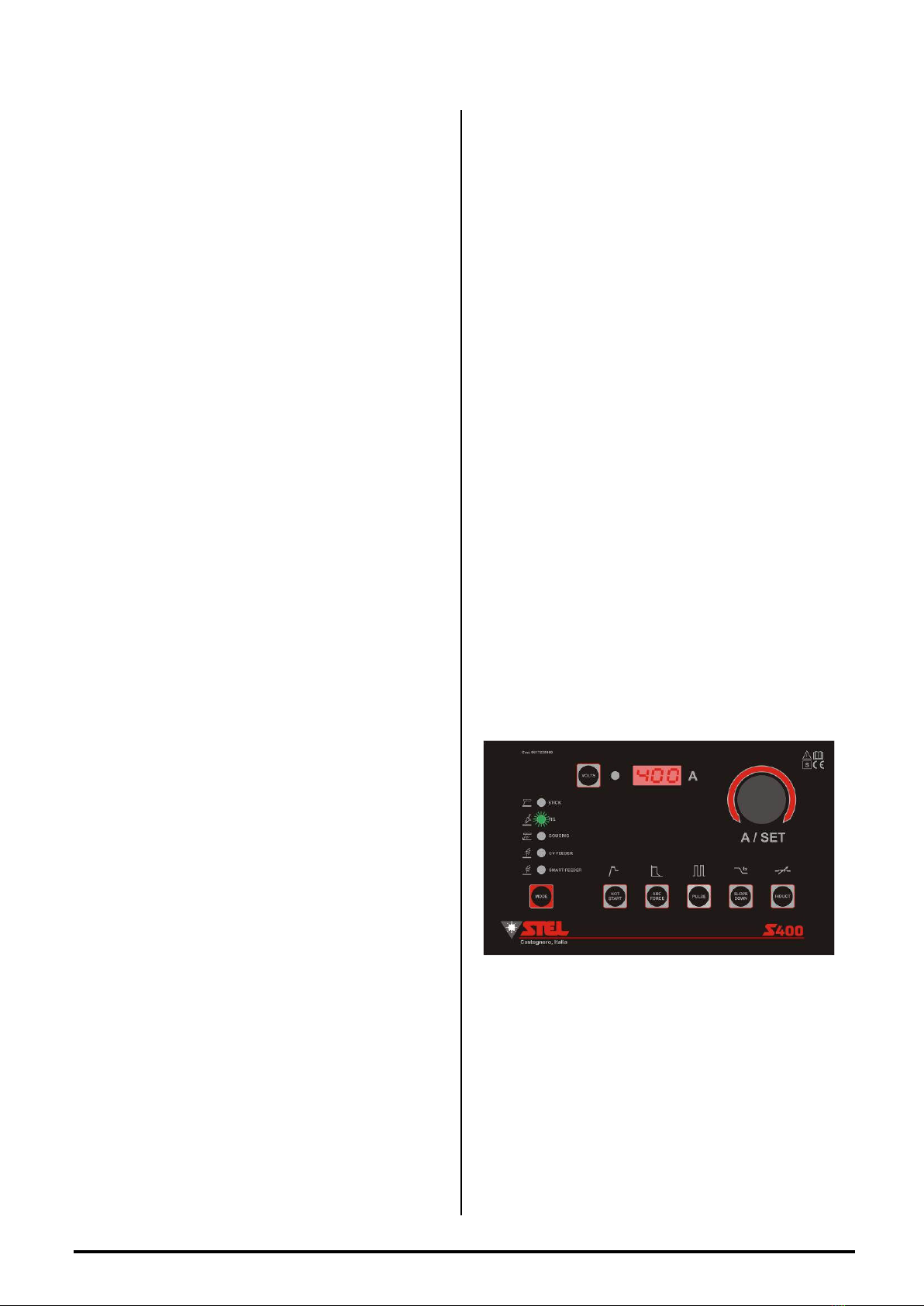

5) Press the MODE (ref.6) button to select the

L CTROD mode, indicated by the LED (ref.1);

6) Set the welding current with the encoder

A/SET (Fig1,ref.12).

7) Proceed with welding.

HOT START SETTING

Pressing the Hot start button (Fig1,ref.7) the

message Hs appears on the display and turning

the A/S T encoder (Fig1,ref.12) it is possible to

adjust the Hot start value.

H.S.= 0-100%

ARC FORCE SETTING

Pressing the Arc Force button (Fig1,ref. 8) the

word AF appears on the display and by turning the

A/S T encoder (Fig1,ref.12) it is possible to adjust

the Arc Force value.

A.F.= 0-500%

PULSE MODE ACTIVATION

Pressing the Pulse button (Fig1,ref.9) the message

Pul appears on the display and turning the A/S T

encoder (Fig1,ref.12) clockwise or anti-clockwise

activates the pulse ON or deactivates it OFF.

The active function is indicated by the flashing of

two dots on the display.

Pulse parameters are not editable.

V.R.D.

(AVAILABLE ONLY IN

MMA / TIG

MODE)

V.R.D. MANAGEMENT

The initials V.R.D. stand for VOLTAG

R DUCTION D VIC , which is a system for

reducing the no-load voltage (OCV). When the

V.R.D. is installed in a welding machine it reduces

the maximum no-load voltage to a safety voltage

which is normally less than 18V.

- The V.R.D. is used as an additional aid for

operator safety.

- The procedures for safety at work must always be

carried out with attention.

V.R.D. ACTIVATION

1) Turn on the generator,

2) Hold down the MOD button (Fig1,ref.6) on the

front panel of the machine for about 4 seconds,

then release the button; the welding mode L D

flashes (V.R.D. FUNCTION ON V out 18V). The

VRD mode remains engaged even after the

machine is switched off and on again

V.R.D. EXCLUSION

1) Turn on the generator,

2) Hold down the MOD button (Fig1,ref.6) on the

front panel of the machine for about 4 seconds,

then release the button; the welding mode L D

remains fixed (V.R.D. FUNCTION excluded). The

VRD mode always remains excluded even after

the machine is switched off and on again.

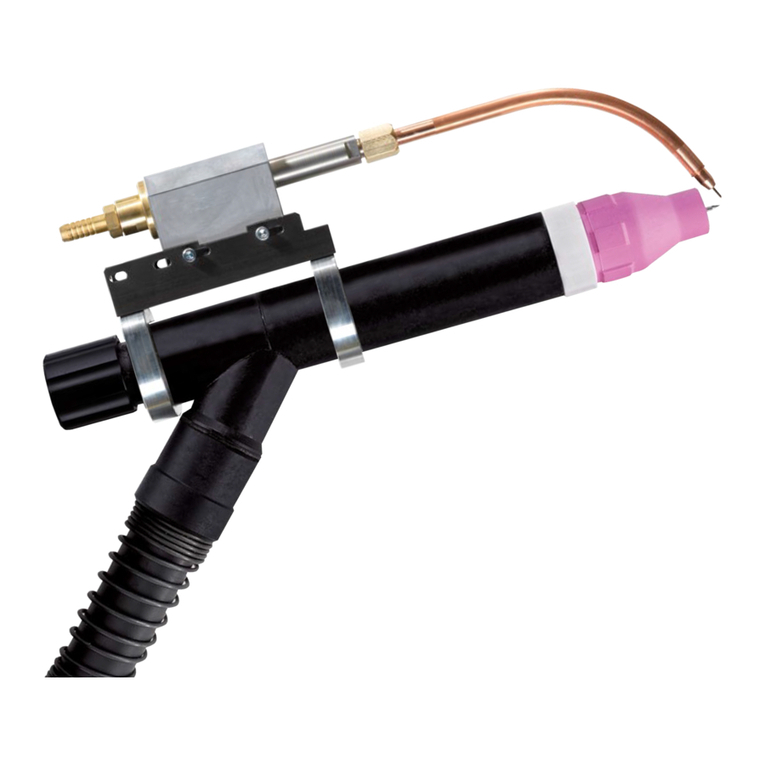

PREPARING FOR TIG

WELDING

1) Respect the instructions previously provided

regarding the primary connection and installation;

2) Connect the earth cable to the dinse socket.

Positive polarity ( + );

3) Connect the torch to the machine socket with

negative polarity ( - );

4) Connect the torch gas connector to the gas

connection located on the front of the generator;

5) Press the MOD button (Fig1,ref.6) until

selecting the TIG mode, indicated by the switching

on of the respective L D (Fig1,ref.2);

7) Set the welding current with the adjustment

encoder A/S T (Fig1,ref.12);

8) Proceed with welding.

SLOPE-DOWN SETTING

Pressing the Slope Down button (Fig1,ref. 10) the

message Sld appears on the display and by

turning the A/S T encoder (Fig1,ref. 12) it is

possible to adjust the slope down value.

Slope down time = 0.1-10 seconds