STM ROCKETBOX 2.0 User manual

POWER

Standard 110V

8 Full Load Amps

5-1/2 ft. Cord Length

SOFTWARE &

UPGRADES

HD 7" Responsive Touch Control Panel

with Data Log and Remote Access Capabilities

OPERATION Patent-Pending Pneumatic Leveling System

CYCLE

CUSTOMIZATION

Single Cycle Operation with

Customizable Run Settings

TRAINING Integrated Training Mode with Step-by-Step Tutorials

VOLUME

CAPACITY 453, 143 or 72 Pre-Rolls Every Cycle

MATERIALS

Encased in SAE 304 Stainless Steel

Heavy Duty Caster Wheels (for transport)

Aluminum & Other Food Grade Components

WEIGHT &

DIMENSIONS

Approximately 300 lbs

Machine Dimensions 24" L x 37" H x 27" W

PAPER

COMPATIBILITY Compatible with 84, 98, and 109 mm cones

COMPLIANCE

OSHA Compliant

UL-Listed Components

100% Food-Grade

Emergency Stop System

LIFE CYCLE 10 Years

Sesh Technologies Manufacturing, Inc.

3223 North Market Street, Spokane, WA 99207

Phone: (509) 204-3164 | Web: www.stmcanna.com

USER MANUAL V1.4

ROCKETBOX 2.0 ™

Table of Contents ......................................... 1

Break-In Procedure ...................................... 2

Components ................................................. 3

Lift Plate ........................................................ 5

Adaptor Plate ............................................... 6

Adjustable Top Tray ..................................... 7

Loading & Unloading Cones ....................... 9

Getting Started ........................................... 10

1

TABLE OF CONTENTS

Operation Of Machine ............................... 11

Touch Screen .............................................. 12

Startup Manual .......................................... 13

Input Density Screen ................................. 14

Parameters/Cycle Run ............................... 15

Density Testing ........................................... 16

Cleaning and Maintenance ....................... 19

Terms of Business ...................................... 20

Thank you for being a valuable and loyal client

of STM. Our goal is to bring our customers the

very best in product quality and customer

service. We value your feedback and use it to

evaluate what to improve and/or update in

our existing product line.

The RocketBox™ uses a direct funneling

system to deliver contaminate-free material

into the selected pre-rolls when used properly.

The Top Tray funnels are directly inserted into

the opening of the pre-roll cones. This only

allows what is being fed onto the Top Tray to

enter the desired pre-rolls in the Bottom Tray.

After setting up the RocketBox™, run the machine through

multiple cycles with each of your tray systems - empty and

unloaded. Watch for and remove any debris in-between the

trays and in the bottom of the shaker box. We take great care

to mitigate this during production, however, due to the intense

vibration some debris may appear.

After un-boxing and the initial dry runs are complete, you may

proceed with regular/normal use of the RocketBox™. Until the

machine has been ran for 400 hours, discard all materials

which have dropped inside the bottom of RocketBox™.

*Run time is located on the start screen.

PLEASE ADHERE TO THE RECOMMENDED

GUIDELINES TO BREAK-IN YOUR ROCKETBOX™

After the RocketBox™ has ran for 400 hours you may reuse the

material that has been collected in the bottom of the shaker

box. Only use this product after visual inspection for debris has

been completed.

Visual inspection should always remain part of the

operation for quality control standards.

2

BREAK-IN PROCEDURE

3

COMPONENTS

6. E-Stop Button3. 7" Touch Screen

1. Rubber Flaps

2. Guide Rod

7. Casters

4. Ports

5. Power Switch 1. Rubber Flaps - Helps

prevent material from falling

into the base of machine.

2. Guide Rods - Threaded rods

to guide and secure the top

and bottom trays into machine.

3. 7" Touch Screen- Used for

the operation of machine.

4. Ports- Ethernet, USB, and

AUX connectivity.

5. Power Switch- Turns the

machine on and off.

6. E-Stop Button- Instantly

turns the machine off in case

of an emergency.

7. Casters - Swiveling caster

wheels for easymobility.

4

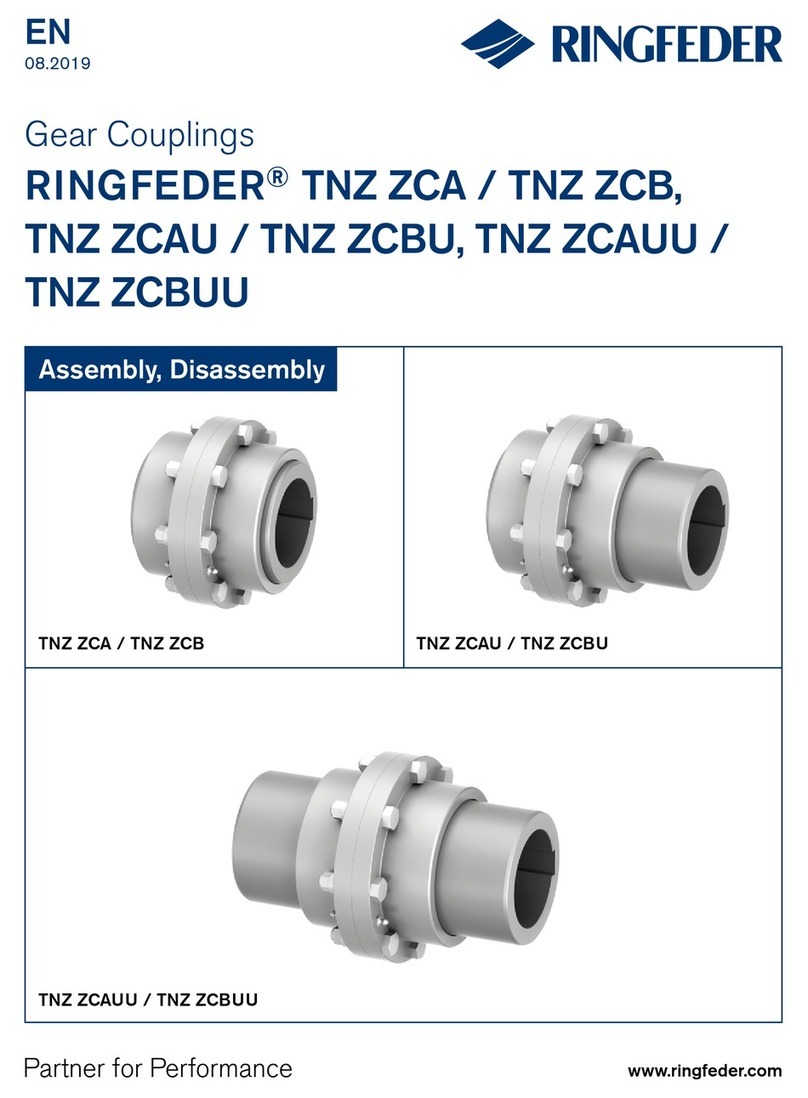

COMPONENTS

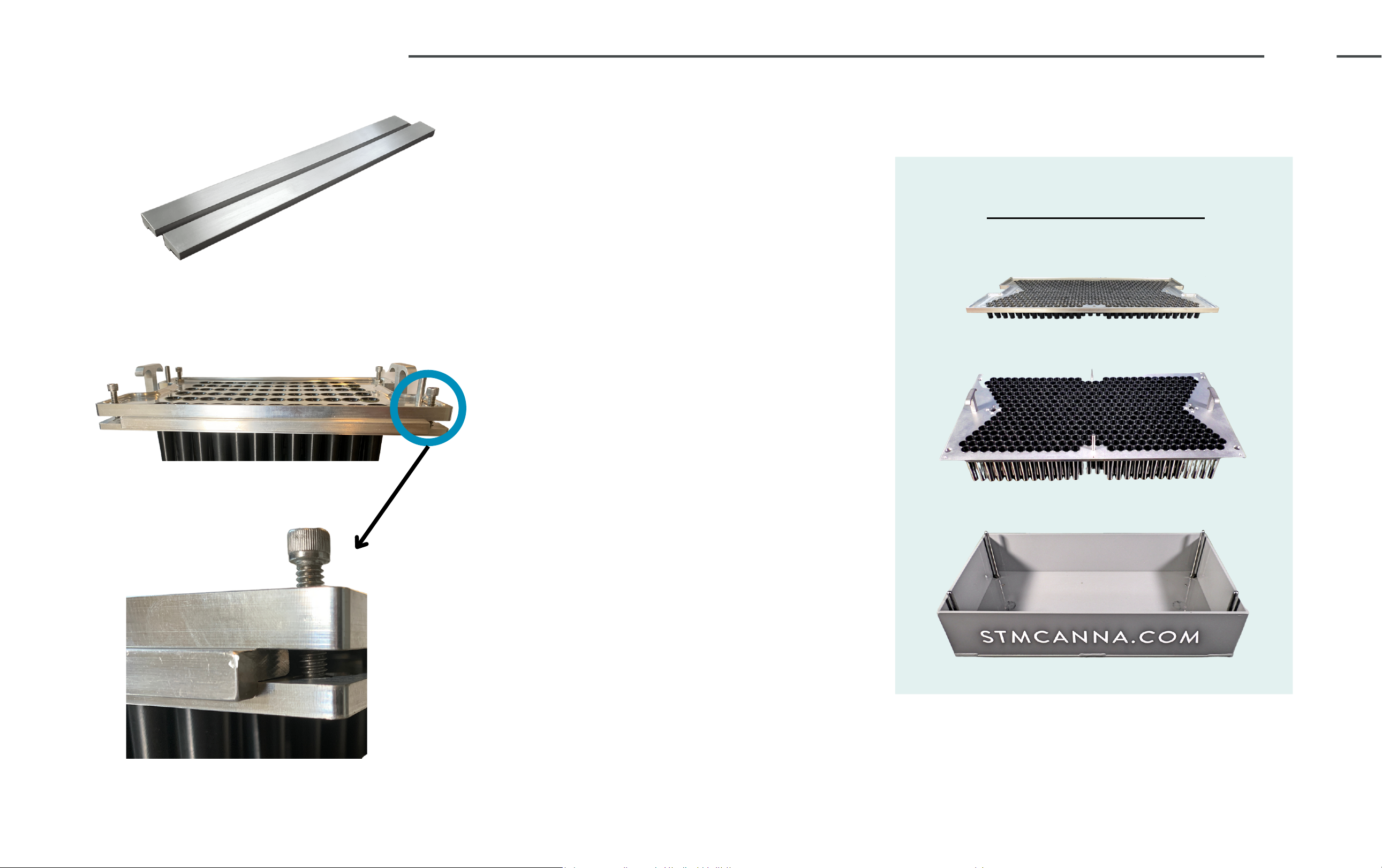

11. Loading Box

8. Adjustable Top Tray

9. Bottom Tray

12. Reset Brackets

13. Riser Bolts

14. Density Beaker

11. Loading Box- Holds Top/Bottom

Trays for easy loading and unloading

and also guides the marrying of the

trays.

8. Adjustable Top Tray- Used to funnel

material into bottom tray and control

desired fill level of pre-rolls.

9. Bottom Tray- Cone holding tray (84,

98, or 109 mm cones).

12. (2) Reset Brackets- To reset the

adjustable top tray to the default 1/4"

spacing.

13. Riser Bolts - Adjusts the lift plate for

84mm (1-1/4) and 98mm (98 Special)

cones. (x2 sets of 4)

14. Density Beaker- 10 mL graduated

beaker used during density tests.

10. Wingnuts + Washers- Threads onto

guide rods to secure Top and Bottom

Tray into Rocketbox.

10. Wingnuts + Washers

5

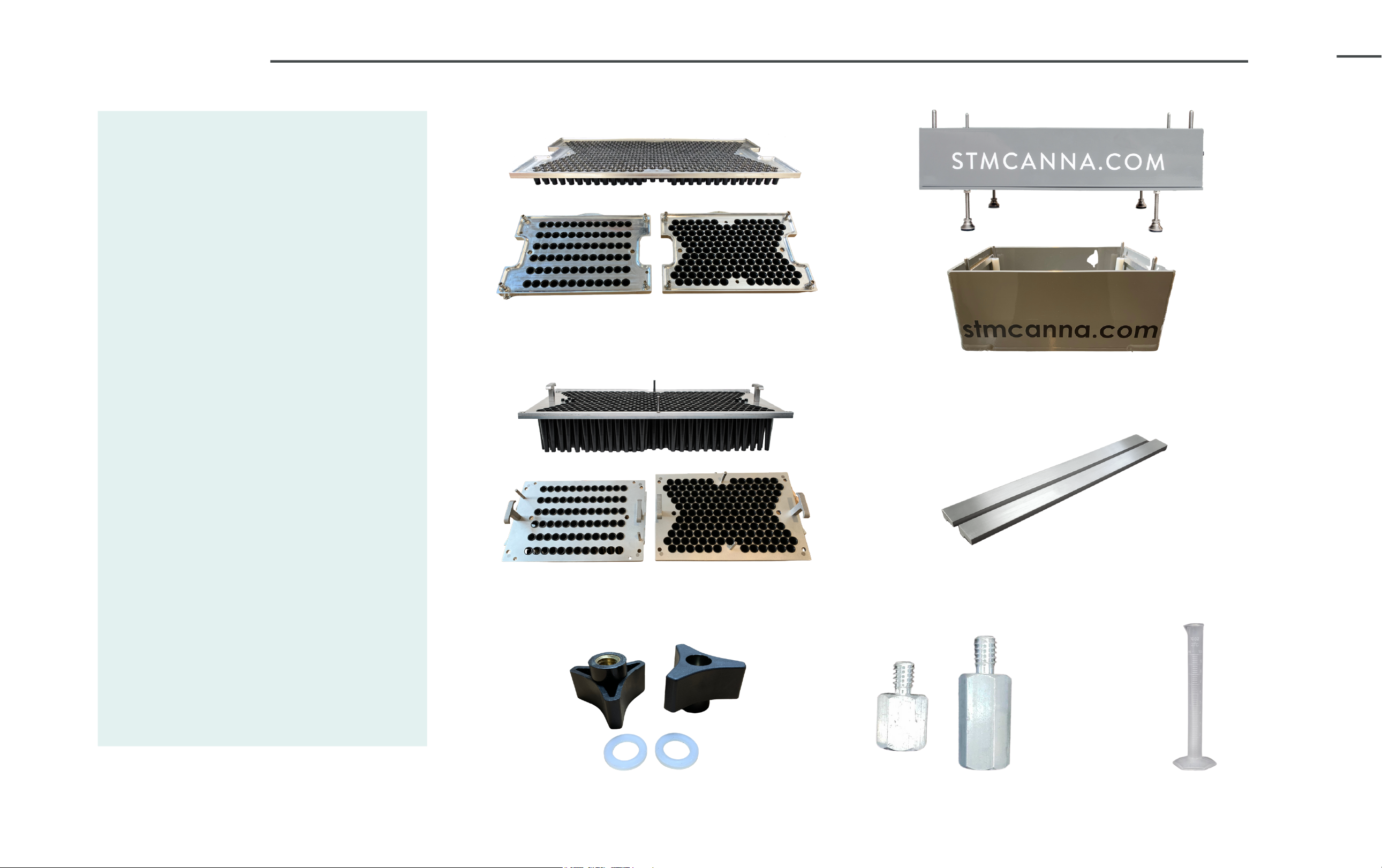

LIFT PLATE

Remove the (4) flathead screws with a 5/32

Allen wrench. Then remove the Lift Plate

completely from the shaker box.

With the lift plate removed, install the

desired Riser Bolts (4) onto the fixed riser

bolts on the bottom of the shaker box.

*See Riser Bolt image to right*

Once Riser Bolts are installed, align and re-

install the Lift Plate. Secure in place with the

four (4) flathead screws using a 5/32 Allen

wrench.

*Riser Bolts should ALWAYS be installed UNDER

the lift plate*

ADJUSTING THE LIFT PLATE

The Lift Plate rests on the four (4) default riser bolts

connected to the bottom of the shaker box.

*Because all papers are rolled by hand, this allows

an even fill line from the bottom up.*

The Lift Plate uses four (4) Riser Bolts to adjust for

98mm (A) and 84mm (B) pre-rolls. The shaker box

always comes with four (4) default riser bolts that

are designed for 109mm King Size pre-rolls.

*DO NOT REMOVE THE DEFAULT SPACERS.*

'A' RISER BOLTS 'B' RISER BOLTS

Used for 98mm pre-rolls Used for 84mm pre-rolls

*Please ensure the correct Riser Bolts are installed prior to use.*

6

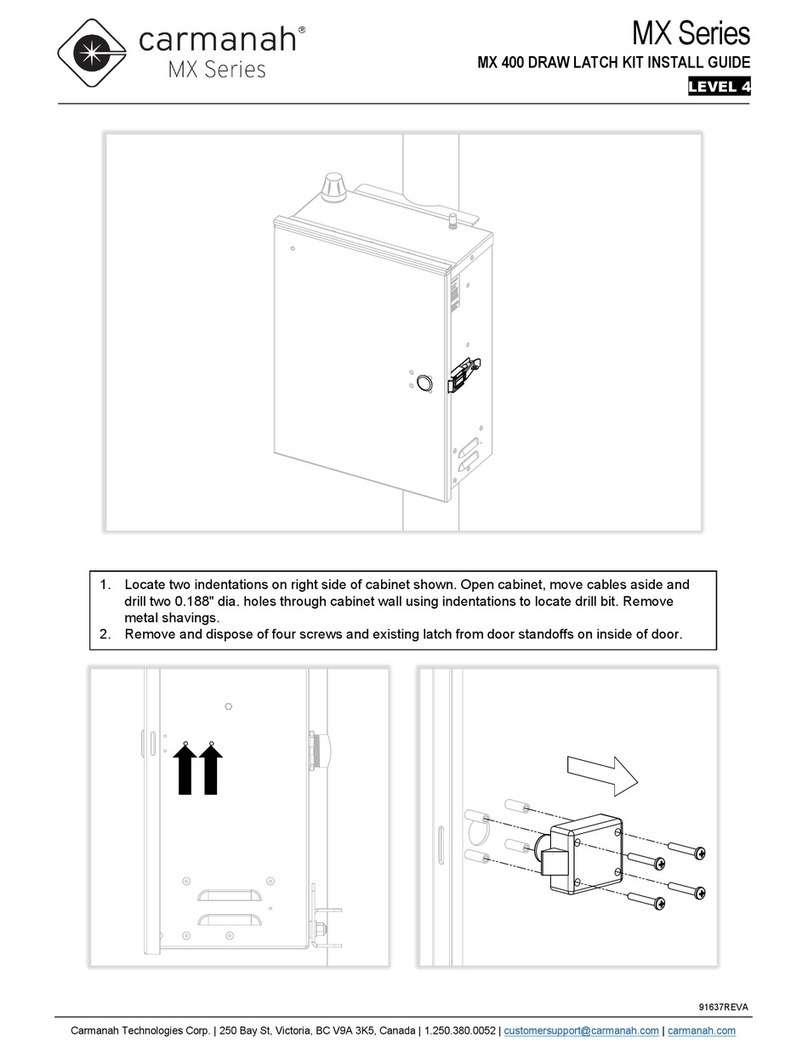

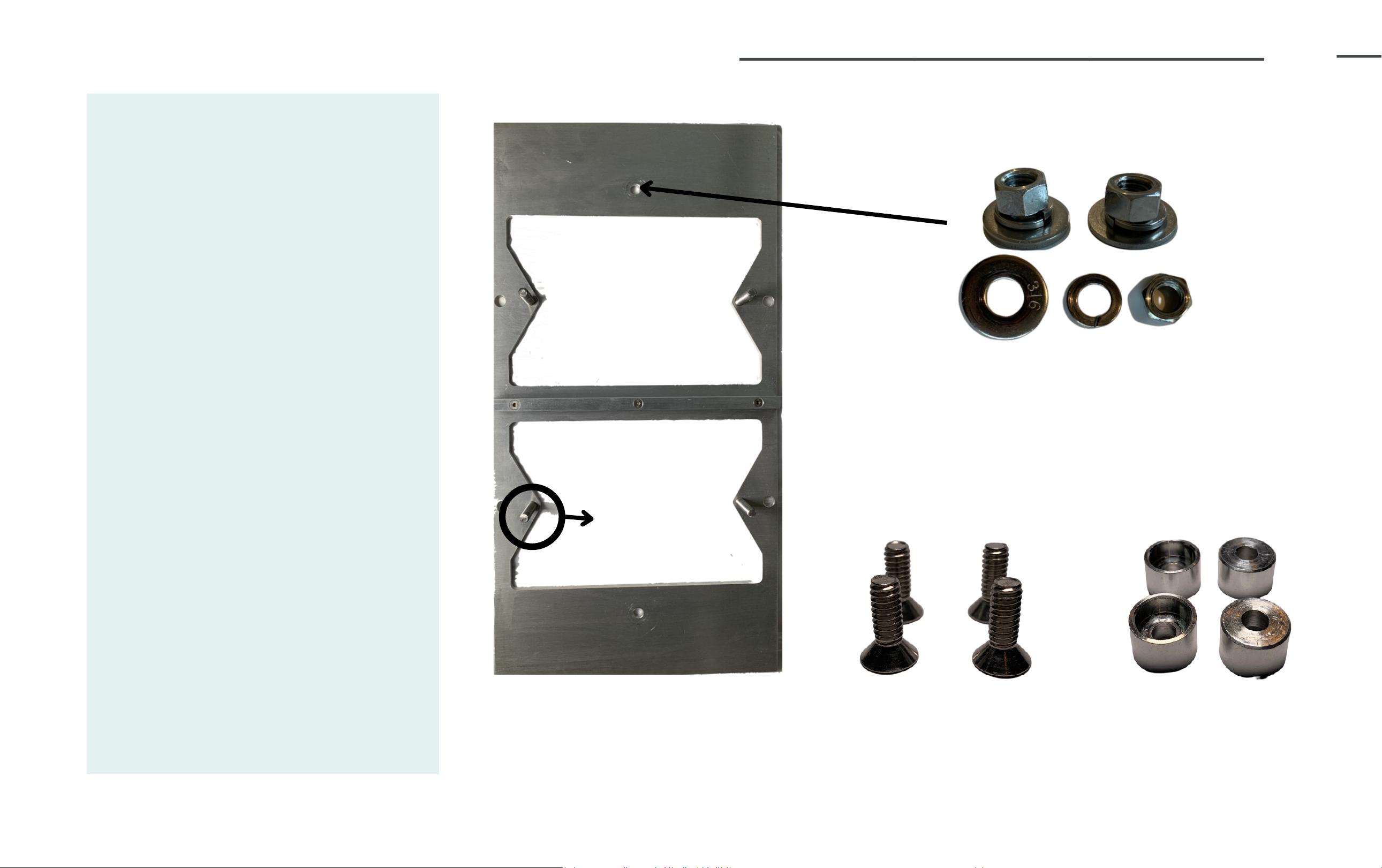

ADAPTOR PLATE COMPONENTS (OPTIONAL)

2. Flat Washer/ Lock Washer / Nut

3. Flat Head Hex Screws

(Long)

4. Hat Spacers

1. Adaptor Plate

5. Top/Bottom

Tray Guide Rods

1. Adaptor Plate- Allows the

Rocketbox 2.0 to run with two (2)

Mini Trays at once - 143ct. or 72ct.

2. Flat Washer / Lock Washer /

Nut- Secures adaptor plate to

Rocketbox 2.0.

3. Flat Head Hex Scews (Long) -

Secures lift plate to bottom of the

shaker box - These are the

LONGER flat head screws. Utilize a

5/32 Allen wrench to

secure/remove.

4. Hat Spacers- Placed ON TOP of

riser bolts. Only used with adaptor

plate install. This compensates for

the added depth from the adaptor

plate.

5. Guide Rods - Threaded rods to

guide and secure the Top and

Bottom trays into Rocketbox.

7

ADJUSTABLE TOP TRAY

Bottom Tray

Top Tray

The Adjustable Bolt touches the Bottom

Tray with the default 1/4" adjustment.

Ensure all (4/6) bolts are adjusted evenly.

Reset Brackets fit in between the Top

and Bottom Tray. Make sure to keep the

Reset Brackets in a convenient location

for future adjustments.

The RocketBox 2.0 includes (2) removable

Reset Brackets to reset the height of the

Top Tray to the default 1/4" setting.

Included Reset Brackets

Placement of Reset Brackets

Placement of Adjustable Bolt

Loading Box

TRAY ASSEMBLY

8

ADJUSTABLE TOP TRAY

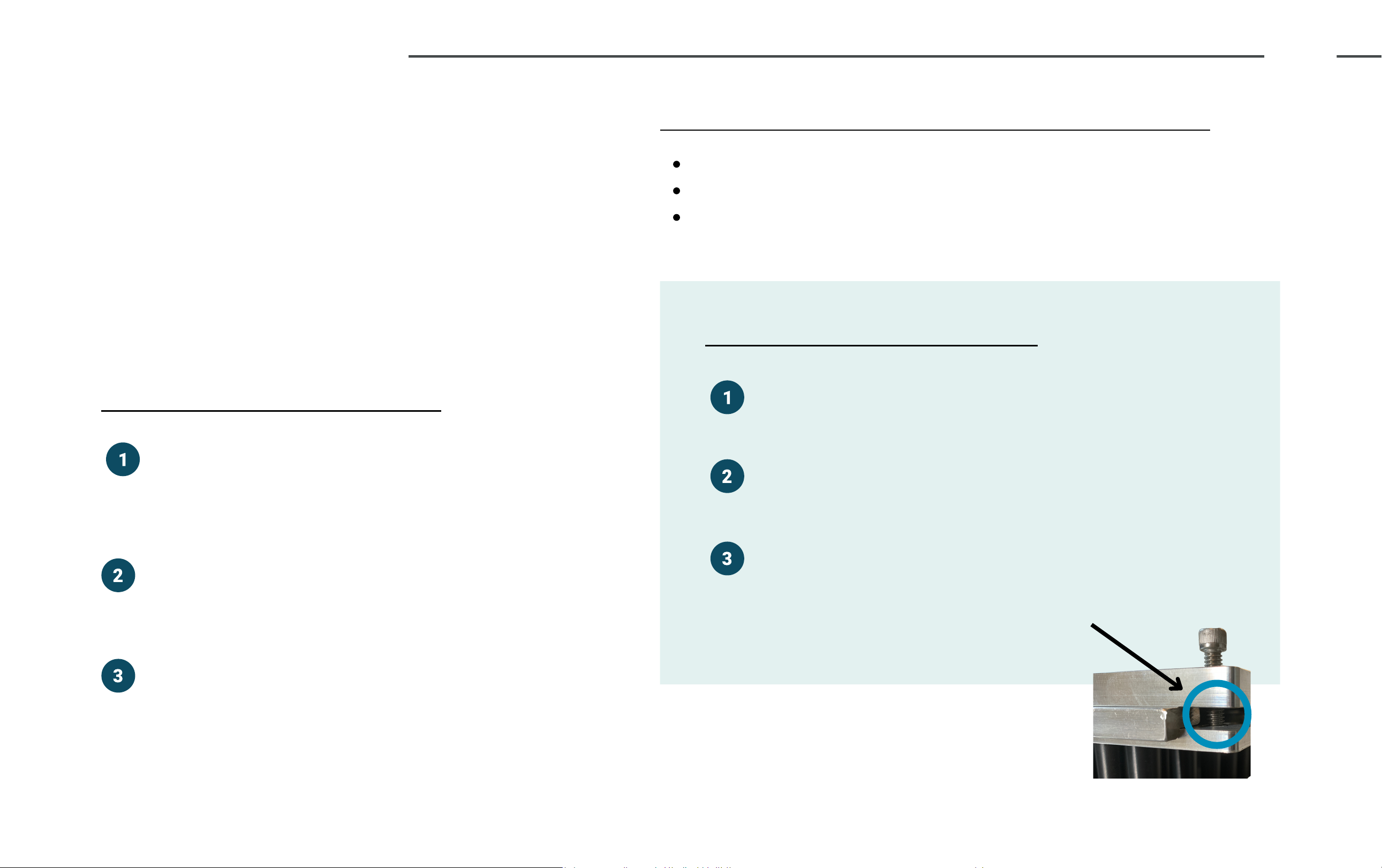

Loosenthe bottom nut on the Adjustment Bolt

with a 7/16" closed-end wrench. Repeat with

each of the (4/6) bottom nuts.

Turn the Adjustment Bolt counter-clockwise to

lower the Top Tray, or clockwise to raise the Top

Tray. Repeat for all (4/6) Adjustment Bolts.

Tighten the Adjustment Bolt bottom nut with

7/16" closed-end wrench to secure into place.

Repeat with all (4/6) bottom nuts.

ADJUSTING THE TOP TRAY

RESETTING THE TOP TRAY

Add the (2) Reset Brackets to each side of the

Bottom Tray. Place Adjustable Top Tray on top.

Loosen all hex bolt lock nuts with a 7/16" wrench.

Repeat for all (4/6) bottom nuts.

Turn the Adjustment Bolts until it just touches the

Bottom Tray. Tighten the hex bolt lock nut to lock

into place. Repeat with all (4/6) bolts. This is the

default 1/4" setting. *See Picture*

The Adjustable Top Tray gives the ability to refine and

control the weight of the pre-rolls. This tool allows

the operator to lower and raise the funnels in and out

of the paper pre-rolls. This will increase or decrease

the overall volume and height of fill lines in the pre-

rolls.

The RocketBox 2.0 is pre-installed with an Adjustable

Top Tray. The default adjustment is set at at¼", easily

adjusted with a 7/16" wrench.

(4/6) ¼” Adjustment Bolts *Dependent on Tray Size*

(4/6) ¼” Bottom Nuts *Dependent on Tray Size*

(2) Removable Reset Brackets

ADJUSTABLE TOP TRAY IS EQUIPPED WITH:

9

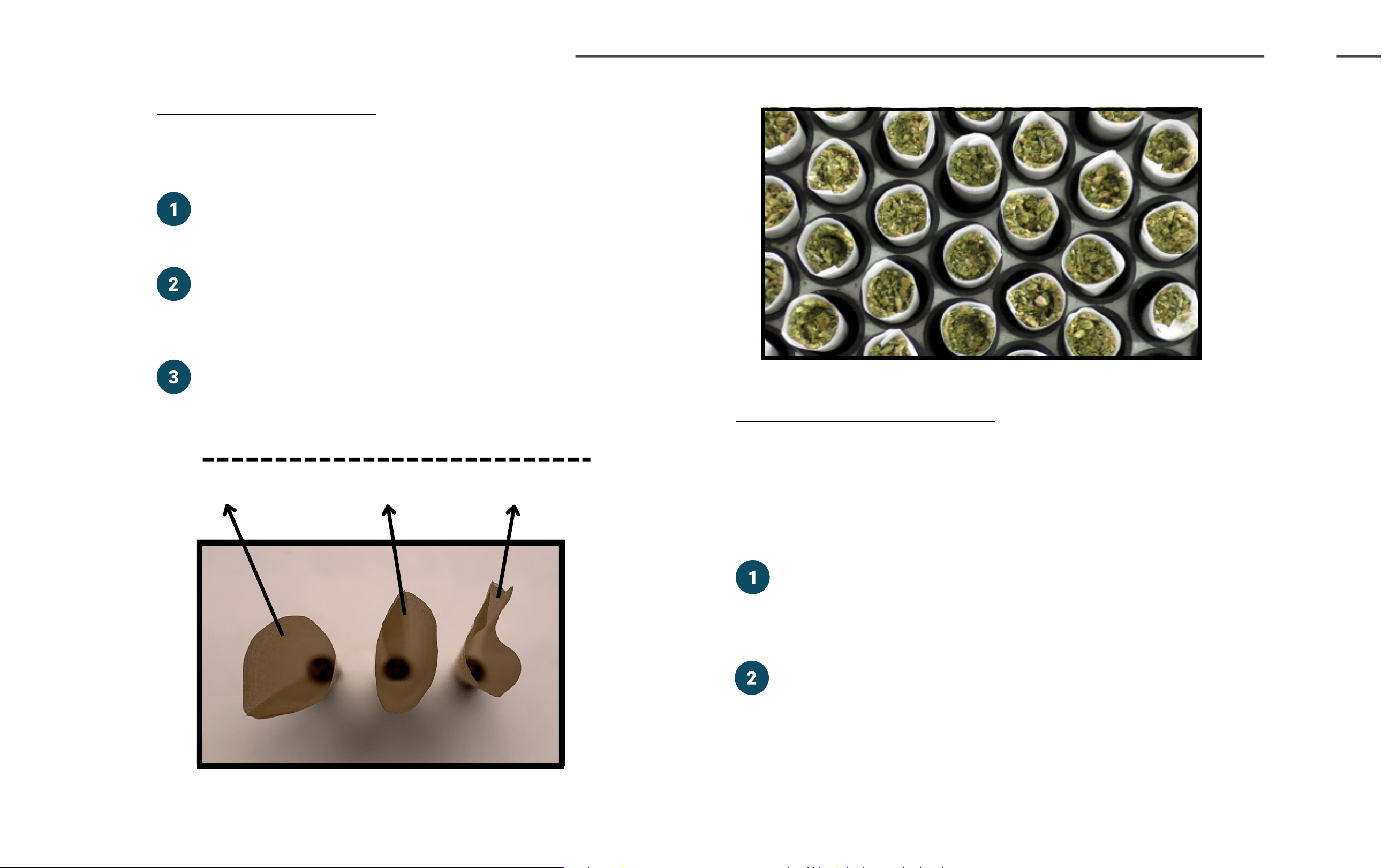

LOADING AND UNLOADING CONES

Place the Bottom Tray into the Loading Box.

Carefully drop cones into the Bottom

Tray. Discard any cones that appear

bent, crushed, or otherwise defective.

Place Top Tray above the Bottom Tray

once loaded with pre-rolls. Marry the

trays together and carefully place into

the RocketBox™.

LOADING CONES

Always use good quality paper cones and discard

all paper cones that appear to be defective.

UNLOADING CONES

Once the cycle in theRocketBox™ is complete and the

PSI is at zero, it is safe to unscrew the wingnuts,

remove the washers, and remove the combined trays.

Remove trays and place into Loading Box.

Set the Top Tray aside. The extra material

on the Top Tray may be reclaimed.

Remove the Bottom Tray from the Loading

Box. Carefully place it onto a solid flat

surface. This will push the cones upwards

and out of the Bottom Tray for easy

examination and removal.

DefectiveAcceptableIdeal

PREPARING WORK AREA

The space required for pre-roll production varies based on

volume needed. See the suggested work areas below:

Grinding Area

Material Prep for

RocketBox™ use

RocketBox Area

For trained person(s) to

operate the RocketBox™

Loading Area

Dedicated to loading

cones into Bottom Trays

Packing Area

Dedicated to closing and

packaging cones

Scoop for Material

Shop Vac

Stainless Steel Chopsticks

Thousandths Scale

70-99% Isopropyl Alcohol

Spray Bottle

Collection Bin

Pipe Cleaners

SUGGESTED TOOLS AND ACCESSORIES

Power OFF Power ON

Power on the RocketBox by plugging it

into a 120v outlet.

Turn the power button clockwise. The

arrow will point upwards.

Once the machine is powered on, the

touch screen will begin powering on.

POWERING ON THE ROCKETBOX

10

GETTING STARTED

11

Helpful Tips

Sift material for better quality pre-rolls.

ALS PSI may display 1 to 2 points lower than settings - this

is normal and to be expected .

Prepare material ahead of time for maximum efficiency.

The key is to have enough material to fill the entire Top Tray

to ensure all cones are optimally filled and packed.

Insert the married Top and Bottom

trays into the RocketBox™. Secure with

washers and wingnuts.

Adjust the settings on the 'Start Up /

Density / Parameters' screens if

necessary. The default settings provide

a good starting point.

Select SYSTEM START to run the cycle.

The airbags will begin to inflate. Once

inflated and the vibratory motor starts,

CYCLE TIME countdown will begin.

Pour material onto Top Tray and

spread evenly to fill all of the cones.

This step may need to be completed at

various speeds, depending on the

material.

After the cycle is complete, an option

to REPEAT RUN (same settings as

previous cycle) or start a NEW RUN

(start from beginning) will appear.

453 Count Tray

72 or 143 Count Tray

OPERATION OF MACHINE

12

TOUCH SCREEN

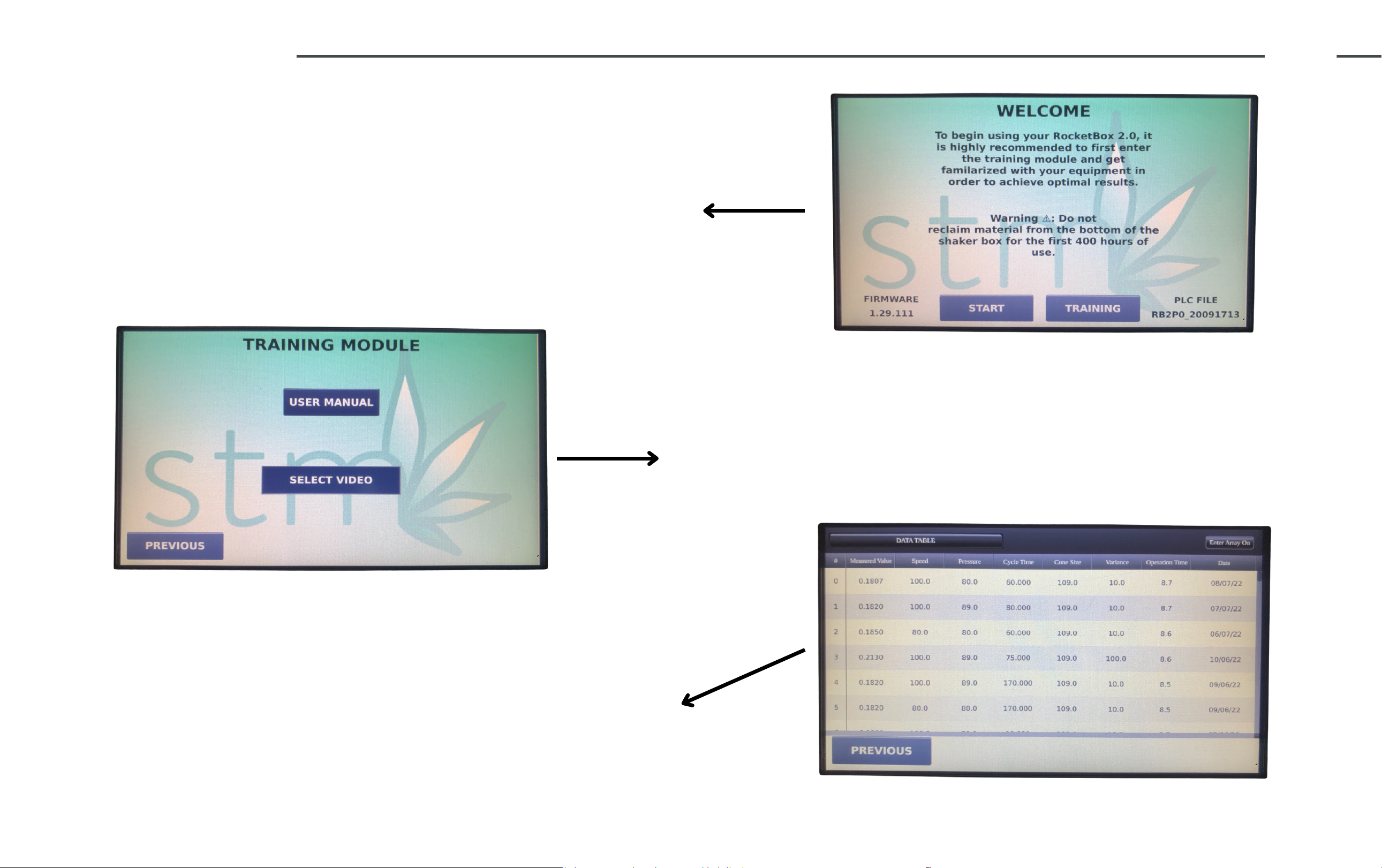

WELCOME SCREEN

The welcome screen will appear after powering on the

machine. Select START to begin a new cycle or select

TRAINING to view the training module.

TRAINING MODULE

Select USER MANUAL to view the manual, or select

TRAINING VIDEOS to access the full series of

RocketBox™ training videos.

DATA LOG

Displays data from up too 100 previous cycles, including

density (measured value), speed, pressure, cycle time,

cone size, variance, operation time, and date.

13

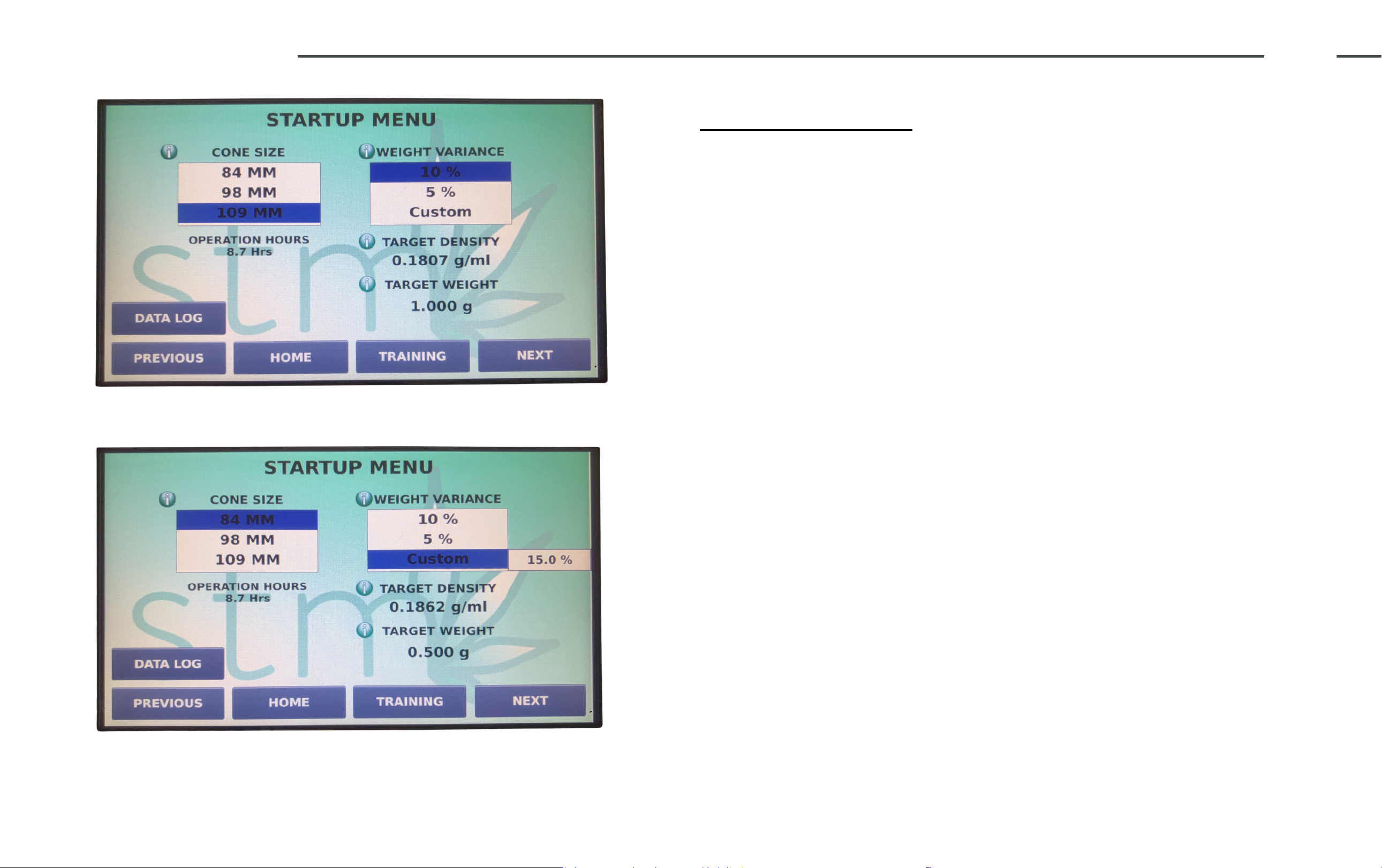

STARTUP MENU

STARTUP MENU

The startup menu will appear after selecting START on the

Welcome screen. On this screen, the operator will select the

cone size and weight variance preferred. Additionally, the

operator can view total operation hours of the machine,

training/data logs, target density, and target weight of pre-roll.

Cone Size

Paper and tray size in use.

Weight Variance

Acceptable variance of target weight based on target

density of material.

Operation Hours

Displays the total run time of the machine.

Target Density

Suggested density target to achieve default target weight.

Target Weight

Weight average that should be achieved if product

density equals the suggested target density.

Data Log

Records the settings of the last 100 runs. Additionally,

the data log can be used for troubleshooting purposes.

14

INPUT DENSITY

INPUT DENSITY

The Rocketbox 2.0 utilizes a pre-installed density calculator to

measure the ground product's average mass per ml of material.

*PLEASE NOTE - These inputs do NOT affect the operation of the

Rocketbox 2.0*

Measured Density

The calculated density of your product - Determined by

performing a density test (See pg. 17)

Calculated Weight

The predicted average internal weight of your pre-rolls based

on your measured density.

% of Desired Weight

Based on Measured Density - this displays the predicted

accuracy of the internal weight of pre-rolls.

Run Density Test

Select this button to open the "RUN DENSITY TEST" Screen

(See pg. 16)

Evaluate

Select this button to open a screen that gives additional

information and tips to improve density numbers. (See pg. 16)

15

PARAMETERS / CYCLE RUN

System Start

Starts the system

System Stop

Stops the system

A.L.S Deflate

Air leveling system deflate time

OPERATION PARAMETERS

Shaker Speed

Vibration intensity range of 10-100%

A.L.S. Pressure

Measured air level system PSI range of 60-95 PSI

Cycle Time

Desired time per run

CYCLE RUN

These parameters directly affect the performance of your machine.

Altering these may impact your pre-rolls internal pack and the overall

weight of your pre-roll.

This screen is where you will turn your machine on and off for a

full production run. It will also display the time it takes for your

airbags to deflate.

**THIS SCREEN WILL APPEAR AFTER

"SYSTEM STOP" IS SELECTED

16

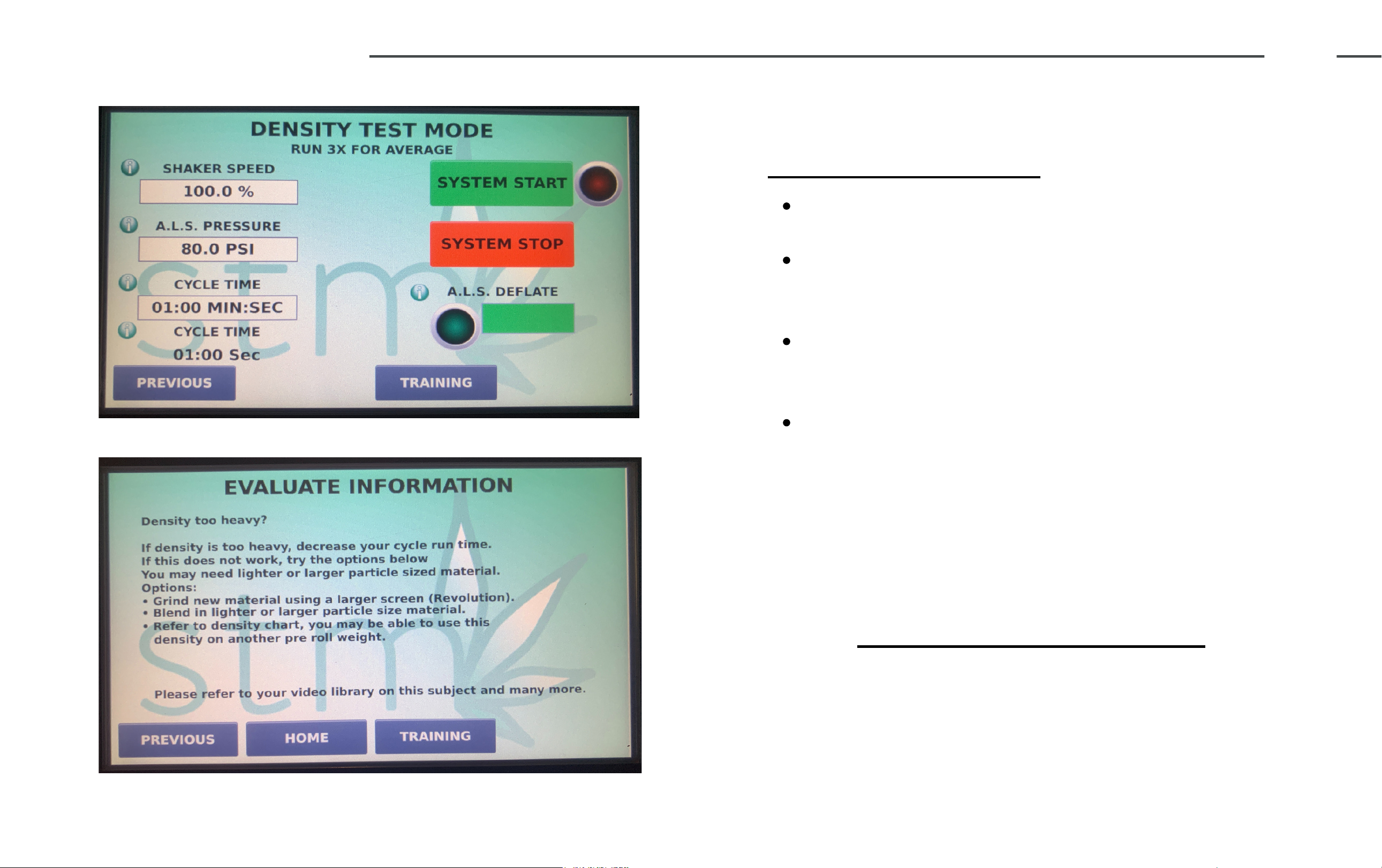

To attain the variance goal, performing a density test

is crucial for success.

Run the Shaker Speed / A.L.S. Pressure / Cycle Time

at settings that will be used during full scale pre-roll

production.

Run the density test THREE TIMES to obtain the

average density of the product to be used in full scale

production

See page 17 for additional details and information.

DENSITY TEST MODE

DENSITY TEST MODE

Note: DENSITY TEST MODE screen will lockout

after three density runs. Power the machine

off and back on to run additional density tests.

EVALUATE INFORMATION

This page provides additional information that

can help anyone to improve the target density

numbers of the product used during pre-roll

production.

17

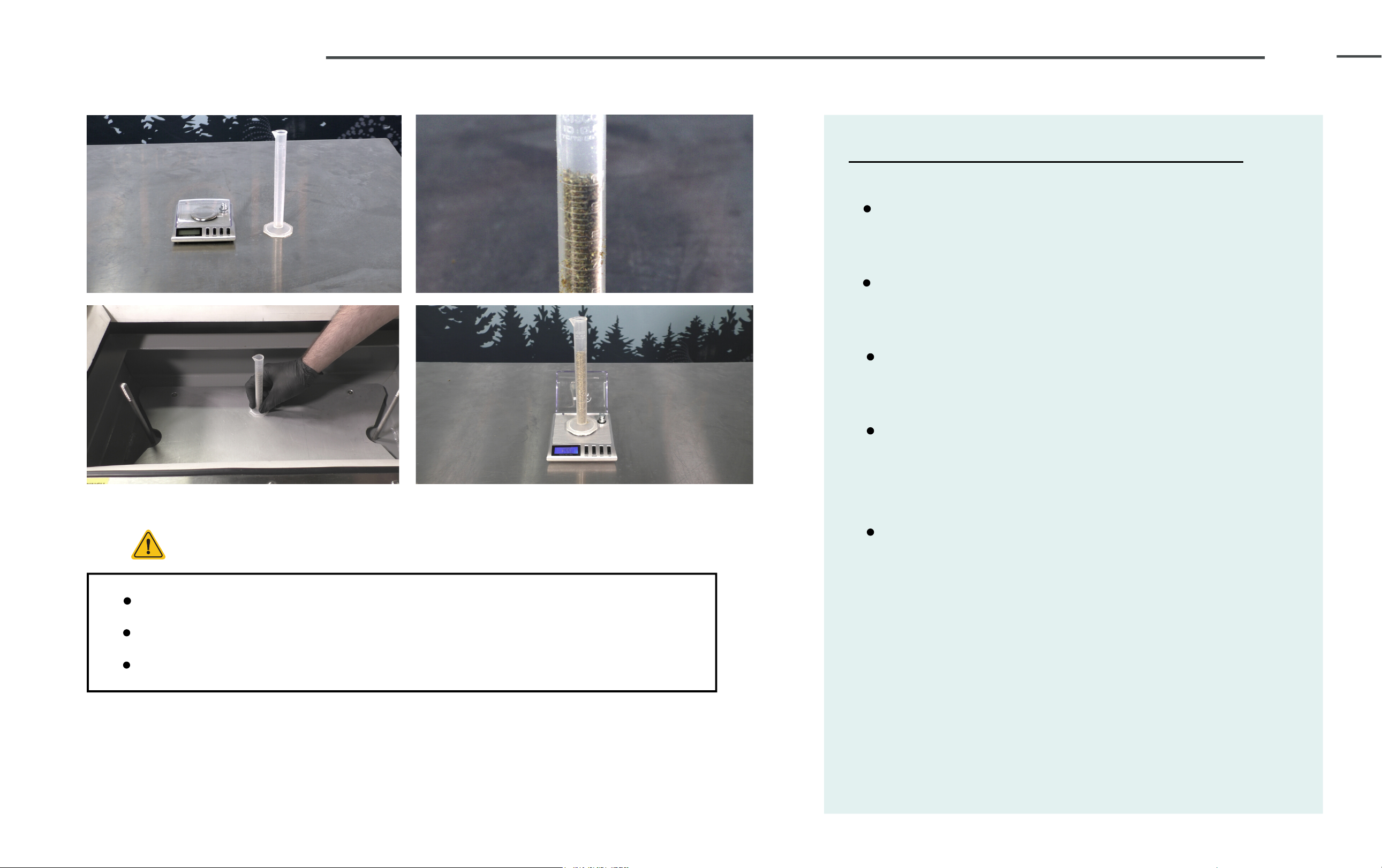

DENSITY TESTING

Repeat density test 3x and average out for optimal results.

Hold beaker in place during density testing.

It is recommended to use a thousandths scale for accuracy.

Helpful Tips

Fill the included beaker just above the 10 mL

line with ground material.

Hold filled beaker firmly onto lift plate and

begin density test - "System Start."

Continue adding material until it settles at

the 10ml fill line while the beaker is vibrating

in the machine.

Remove beaker from machine. Place onto

the tared scale and record weight. Move the

decimal one place to the left - this will be the

calculated density of the tested material.

Utilize this value on the "INPUT DENSITY

SCREEN."

PERFORMING A DENSITY TEST

Tare empty 10 mL beaker on thousandths

scale.

Example: If the scale weight is 1.590, input

0.1590 into the MEASURED DENSITY setting

on the INPUT DENSITY SCREEN.

WHAT IS DENSITY?

Density is a characteristic property of

a substance. The density of a

substance is the relationship between

the mass of the substance and how

much space it takes up (volume).

WHAT IS DENSITY TEST MODE?

Density test mode ensures pre-rolls meet their

target weight. This increases accuracy and

minimizes variance across all 453 pre-rolls.

TheRocketBox™ 2.0's built-in Density Calculator assists

with reaching targeted weight accuracy based on density

of material.

18

DENSITY

Other manuals for ROCKETBOX 2.0

1

Table of contents

Other STM Industrial Equipment manuals

STM

STM RFA Series Instruction Manual

STM

STM NGN-8100 User manual

STM

STM RX Series Instruction Manual

STM

STM MINI-ROCKETBOX CANNA User manual

STM

STM ROCKETBOX User manual

STM

STM ATOMIC CLOSER User manual

STM

STM ROCKETBOX Installation guide

STM

STM REVOLUTION 2.0 User manual

STM

STM MINI-ROCKETBOX PLUS+ User manual

Popular Industrial Equipment manuals by other brands

Brodie

Brodie 9900 Series Installation and operation manual

Chore-Time

Chore-Time Linear Lift 50558 Series manual

PROTA

PROTA ProtaSteel 2021 quick start guide

ABB

ABB HT614283 Operation manual

HOLLISTER-WHITNEY

HOLLISTER-WHITNEY GLV-40S1 Series instruction manual

BVA Hydraulics

BVA Hydraulics CMH6 instruction manual