3

SAFETY

∙When tightening or loosening threaded

connections, always use suitable opened

spanners, but do not use pipe wrenches,

extensions, etc.

1.4.5 Risk of cracks due to water leaks

A poor installation can cause water leaks.

∙Ensure that there is no stress on the

hydraulic pipework.

∙Correctly position the seals.

1.5 Intended use

The product is a state-of-the-art product

which has been constructed in accordance

with recognised safety regulations.

Nevertheless, there is still a risk of injury or

death to the user or others or of damage to

the product and other property in the event

of improper use or use for which it is not

intended.

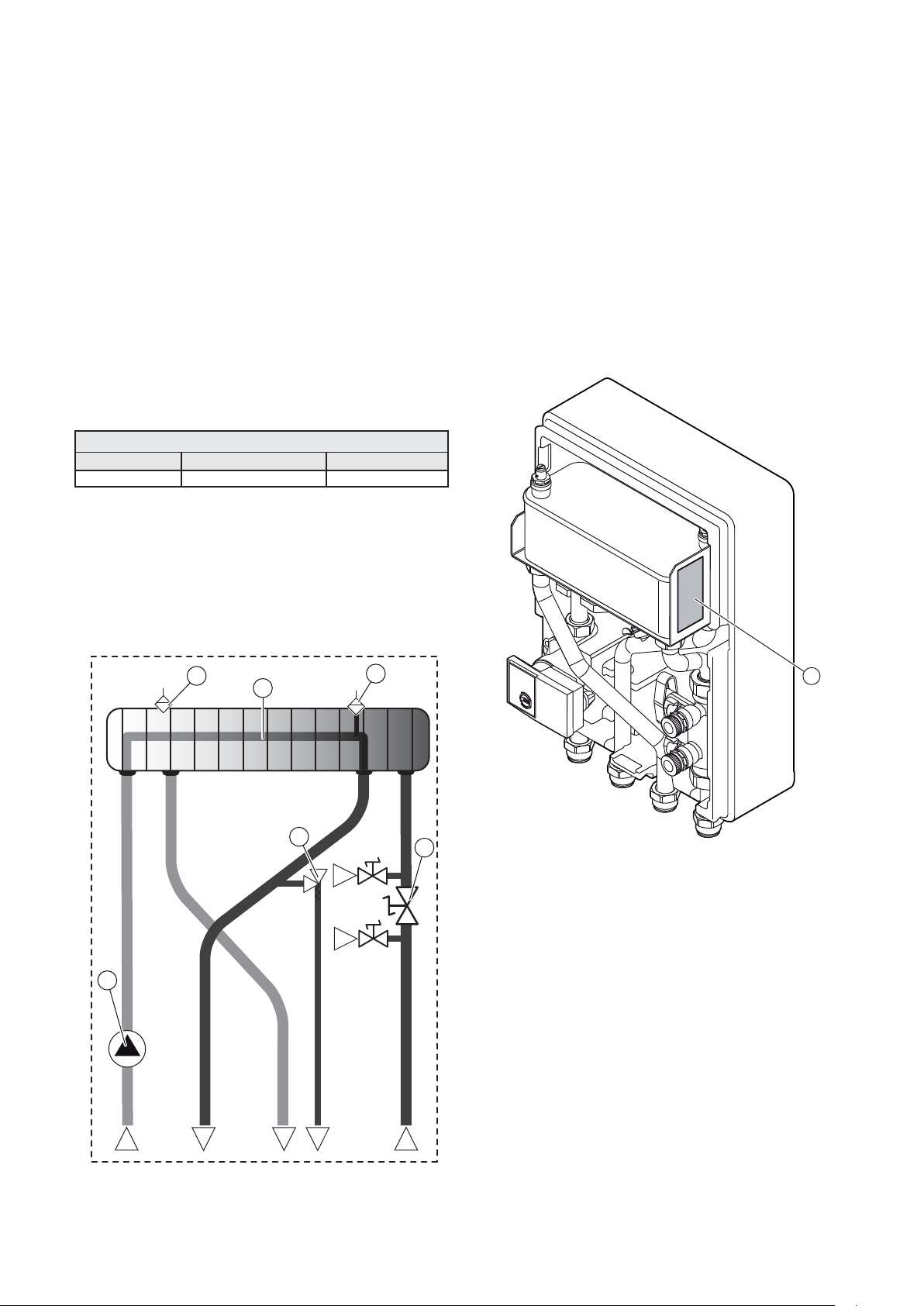

The appliance is intended to be used for

separating the heat pump glycol circuit from

the domestic central heating circuit.

Intended use includes the following:

-observing the included operating,

installation and maintenance instructions

for this product and any other parts and

components of the system

-installing and fitting the product in

accordance with the product and system

approval

-complying with all of the inspection and

maintenance conditions listed in the

instructions.

Any other use than the use described in the

instructions at hand or any use extending the

described use is not intended.

Any direct commercial or industrial use is

also deemed to be improper.

1.6 Rules and regulations (directives,

laws, standards)

1.6.5.1 IMPORTANT

Where no British Standards exists, materials

and equipment should be fit for their purpose

and of suitable quality and workmanship.

The installation of this heating appliance

must be carried out by a competent person

approved at the time by the Health and

Safety Executive and in accordance with the

rules in force in the countries of destination.

Manufacturer’s instructions must not be

taken as overriding statutory requirements.

1.6.5.2 Statutory Requirements

In GB, the installation of the heating

appliance must be carried out by a

competent person approved at the time by

the Health and Safety Executive and as

described in the following regulations:

- The manufacturer’s instructions supplied.

- The appropriate Buildings Regulations

either The Building Regulations, The Building

Regulations (Scotland), The Building

Regulations (Northern Ireland).

- The Water Supply (water fittings)

Regulations 1999 and water byelaws 2000,

Scotland.

- The Health and Safety at Work Act,

Control of Substances Hazardous to Health

(COSHH).

- Any electrical work must conform to BS

7671 and where applicable Part P of the

building regulations.

Where no specific instructions are given,

reference should be made to the relevant

British Standard Code of Practice.

In IE, the installation must be carried out by

a competent person approved at the time by

the Health and Safety Executive and installed

in accordance with the current edition of

I.S.813 “Domestic Gas Installations”, the

current Building Regulations and reference

should be made to the current ETCI rules for

Electrical Installation.

GB: the following Codes of Practice apply:

BS4814, BS6798, BS5440 Part 1 and 2,