Solution Guide

Bull Rider - 3D Printed Scooter

print and assembly instructions

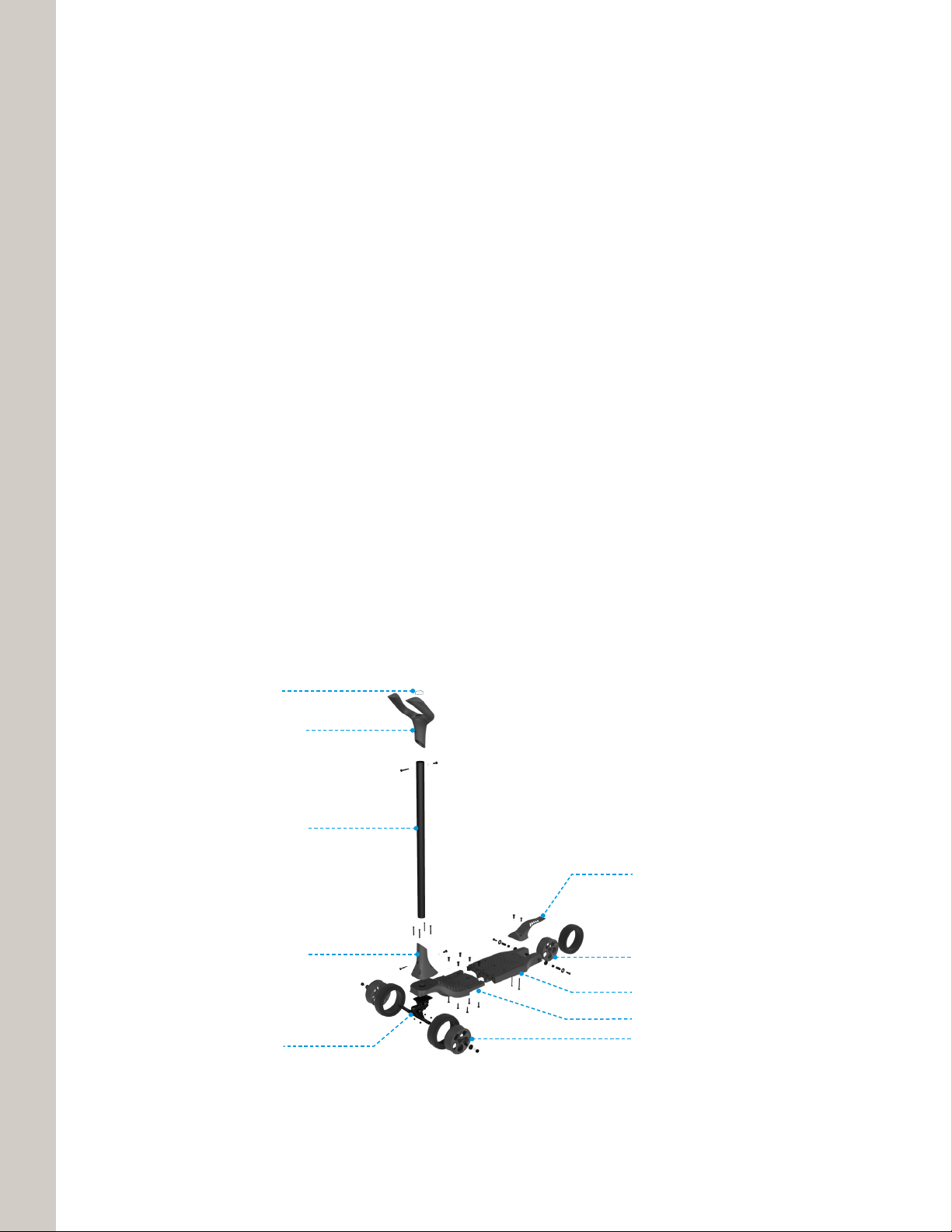

Scooter overview

The Bull Rider was designed by Slicelab in collaboration with Stratasys. The kick scooter is comprised

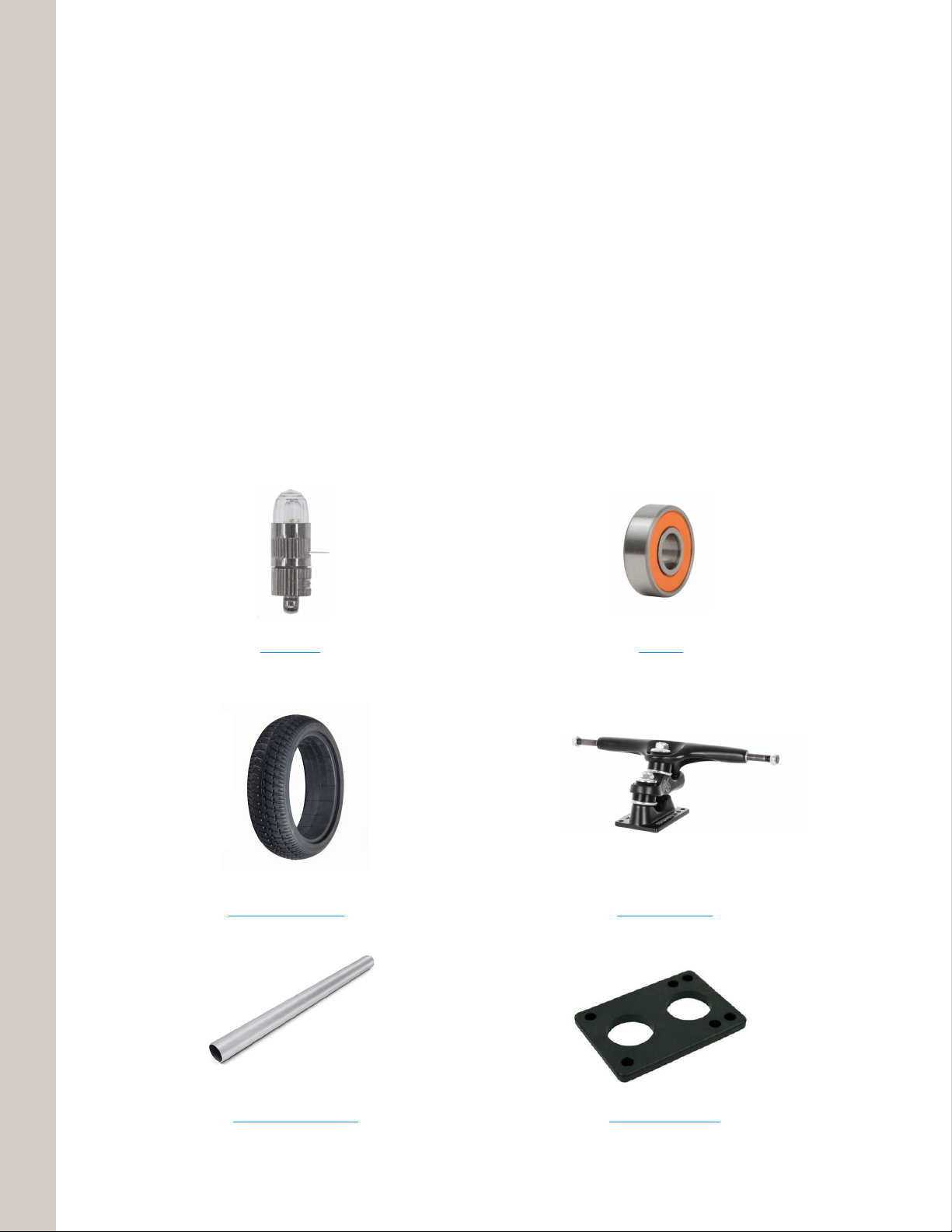

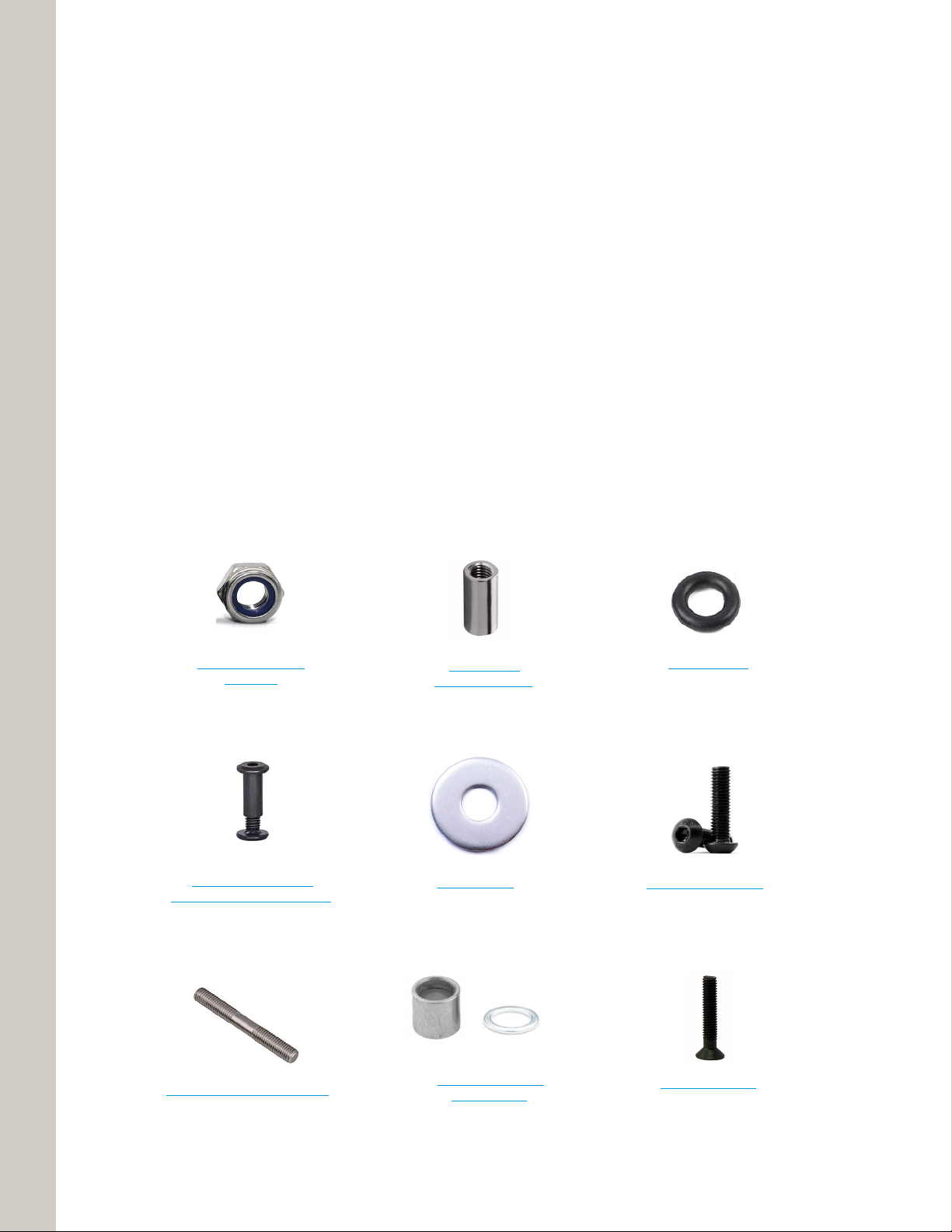

mostly of 3D printed parts designed specifically for the Origin One machine. The additional parts needed

are off the shelf components that can be easily purchased online and customized to user needs. Examples

of such adjustments can be for the users height or weight metrics that impact how one rides the scooter.

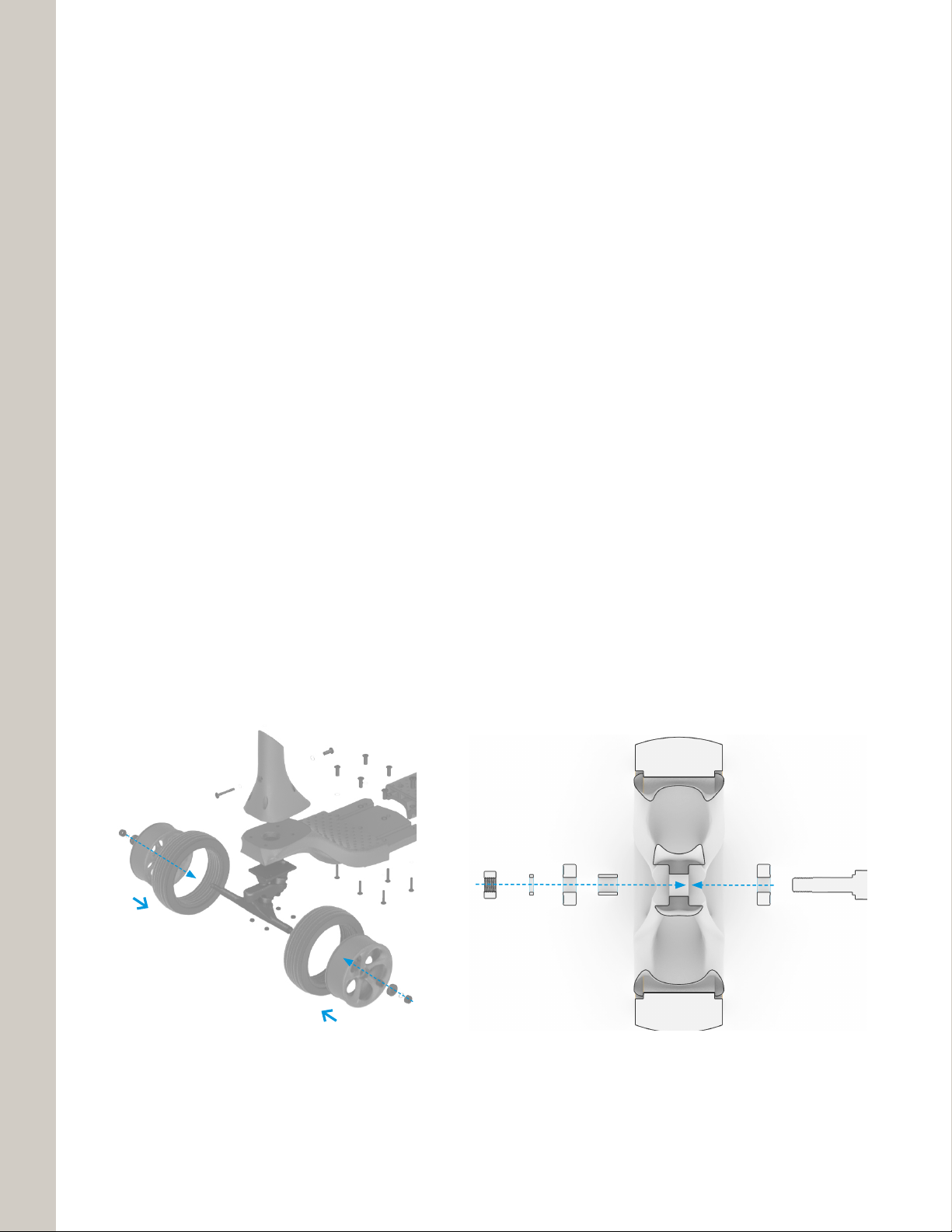

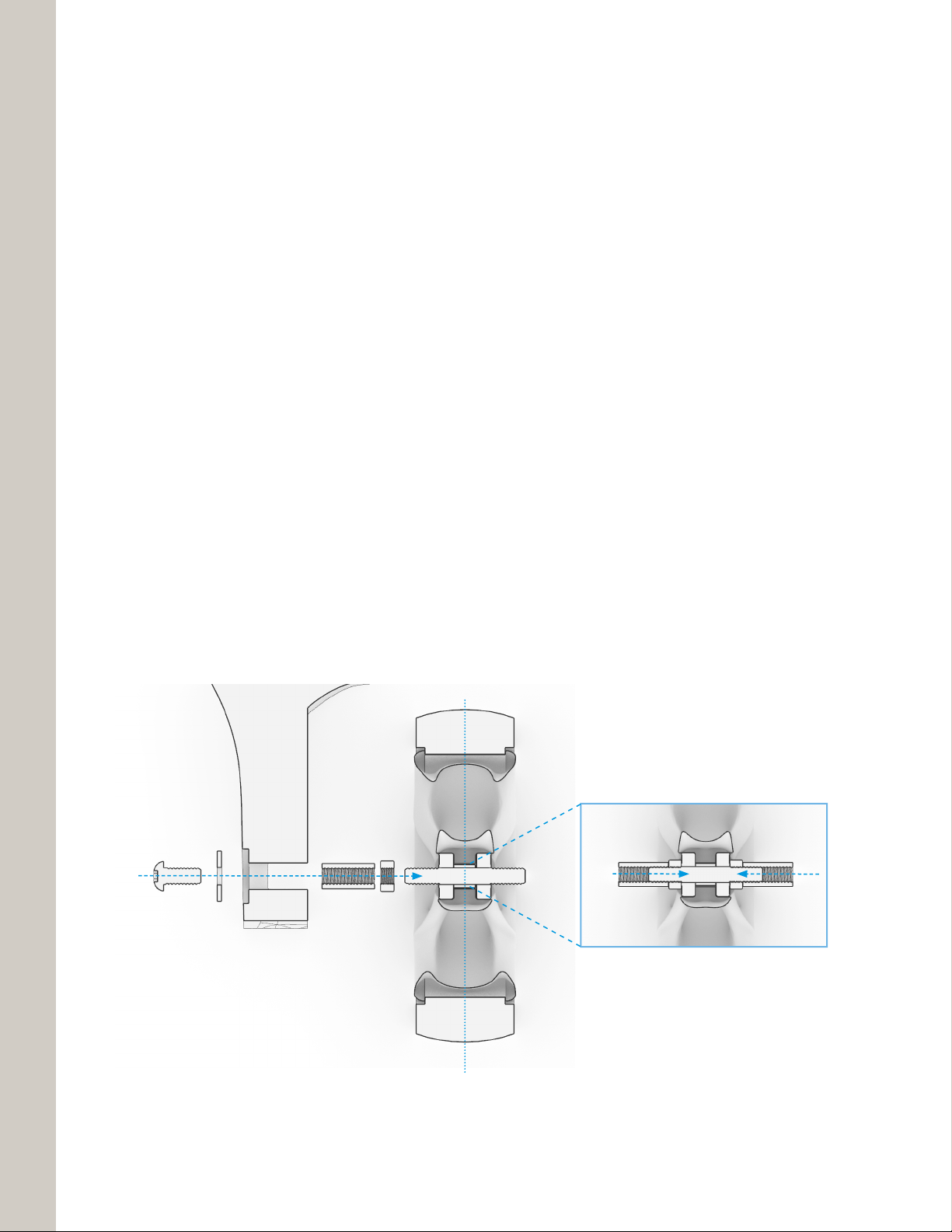

Additionally, there are components like the long-board trucks, that can be tightened or loosened to allow for

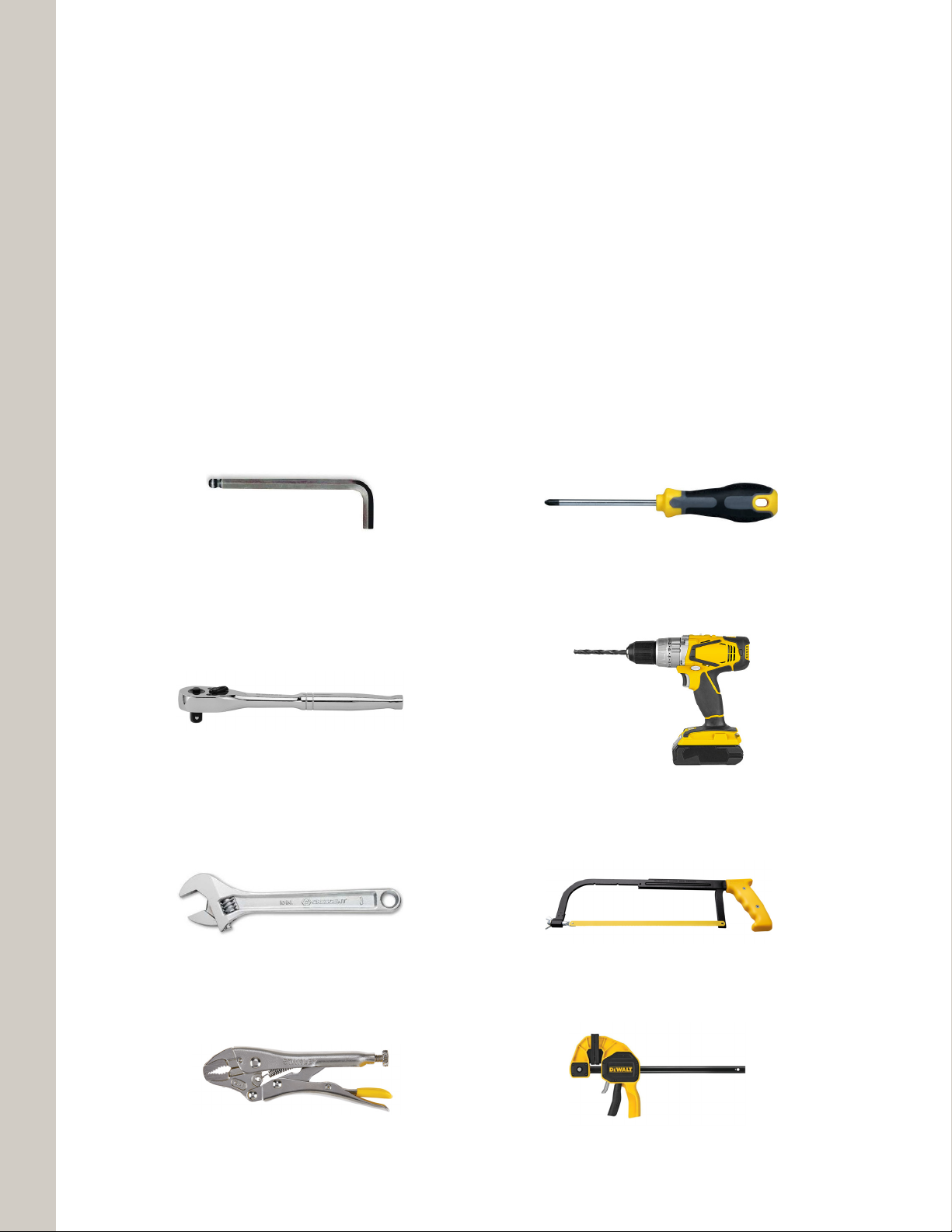

more or less responsiveness in steering. In the following pages, the required tool set and steps to complete

this assembly will be highlighted along with a list of the needed purchased parts and printed parts.