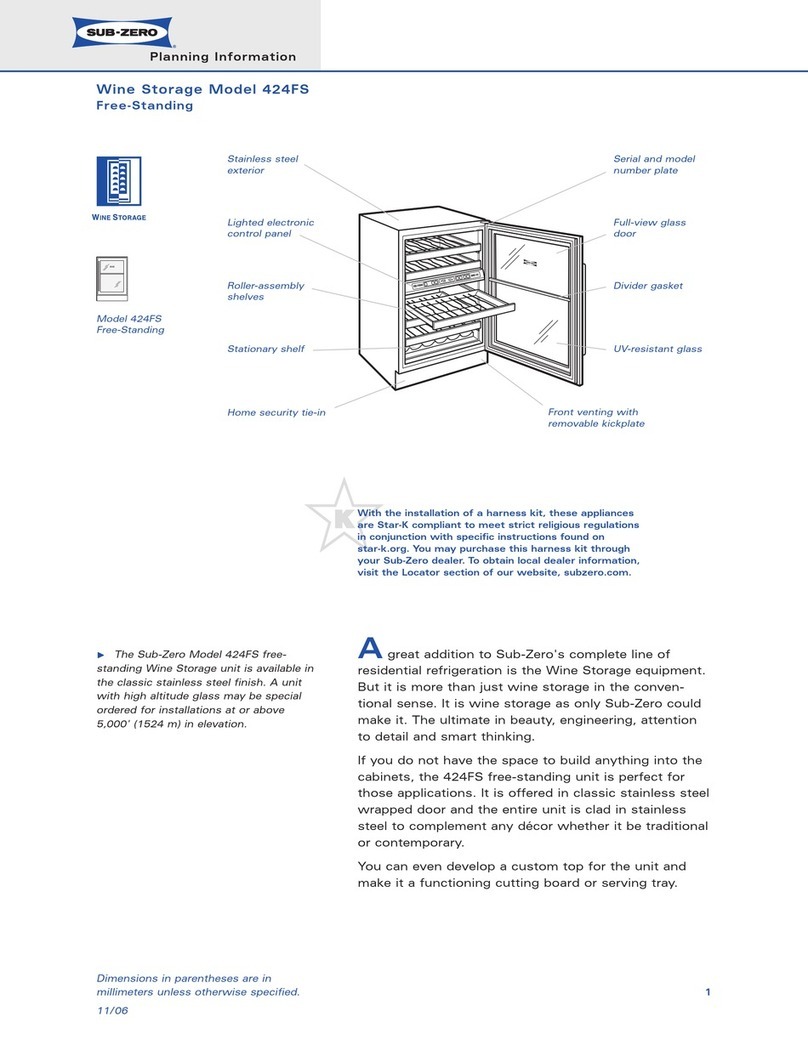

Installation Information Wine Storage

Wine Storage (400-

(400-2

2)

)Series

Series

2-6

#3758410 - Revision C - May, 2014

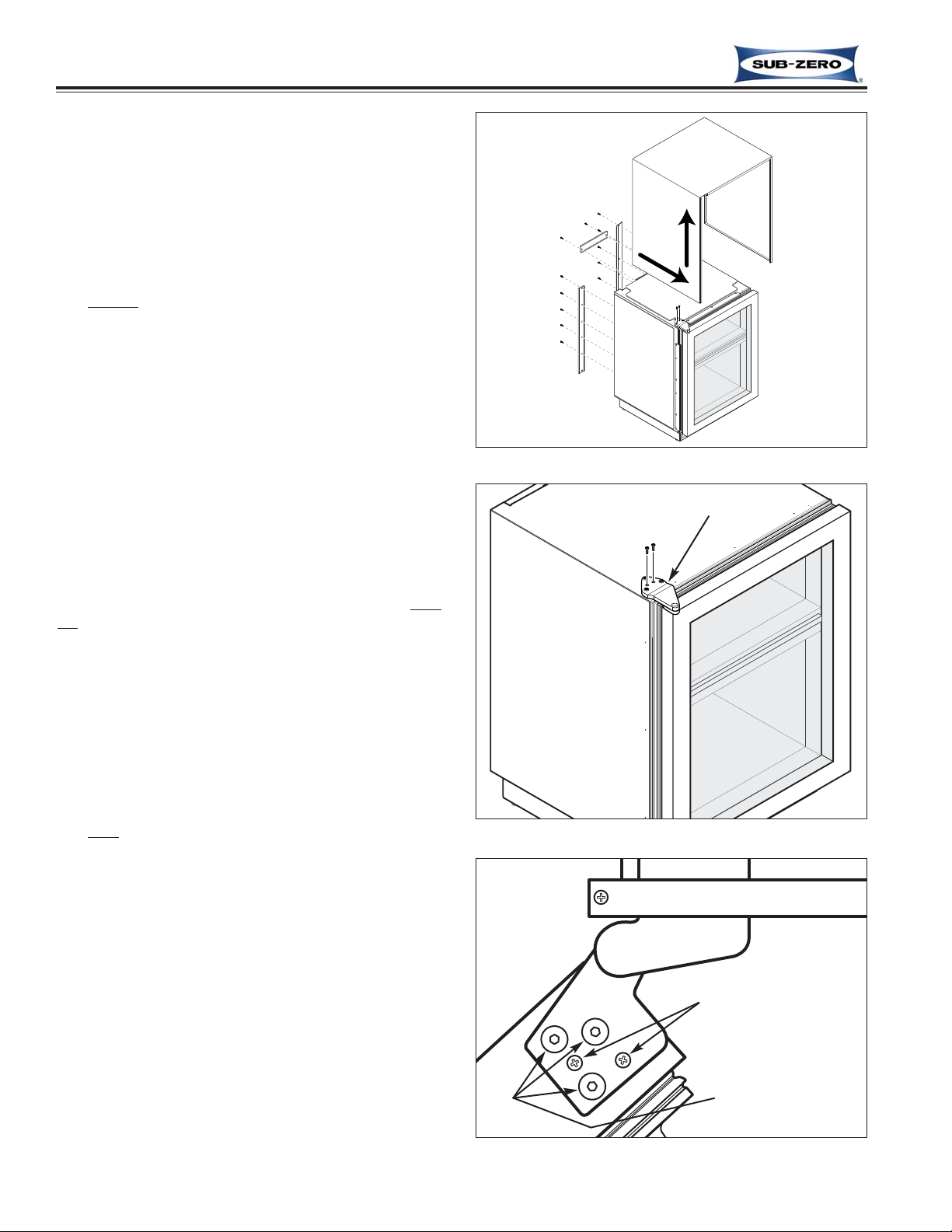

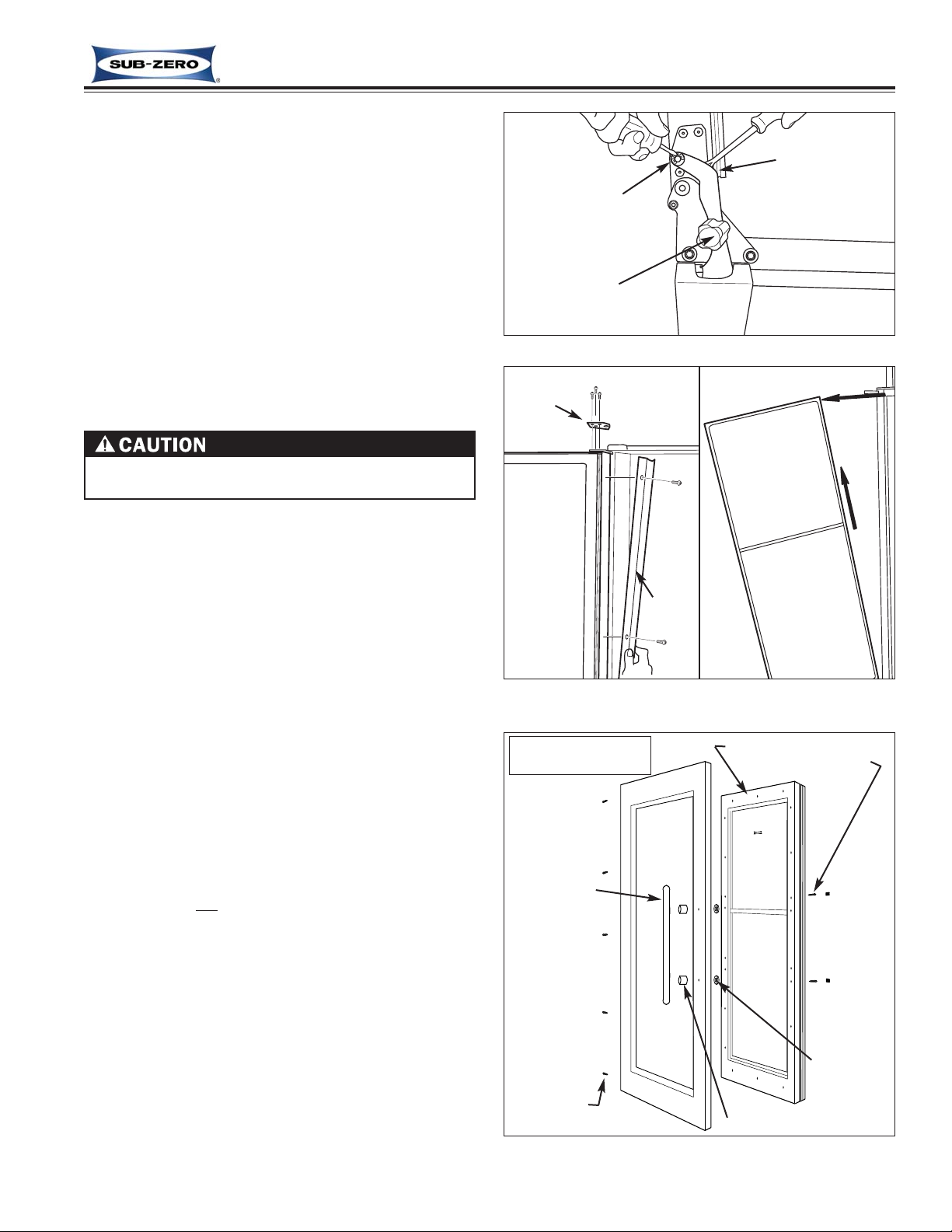

Figure 2-15. Door / Top Cabinet Hinge Adjustment

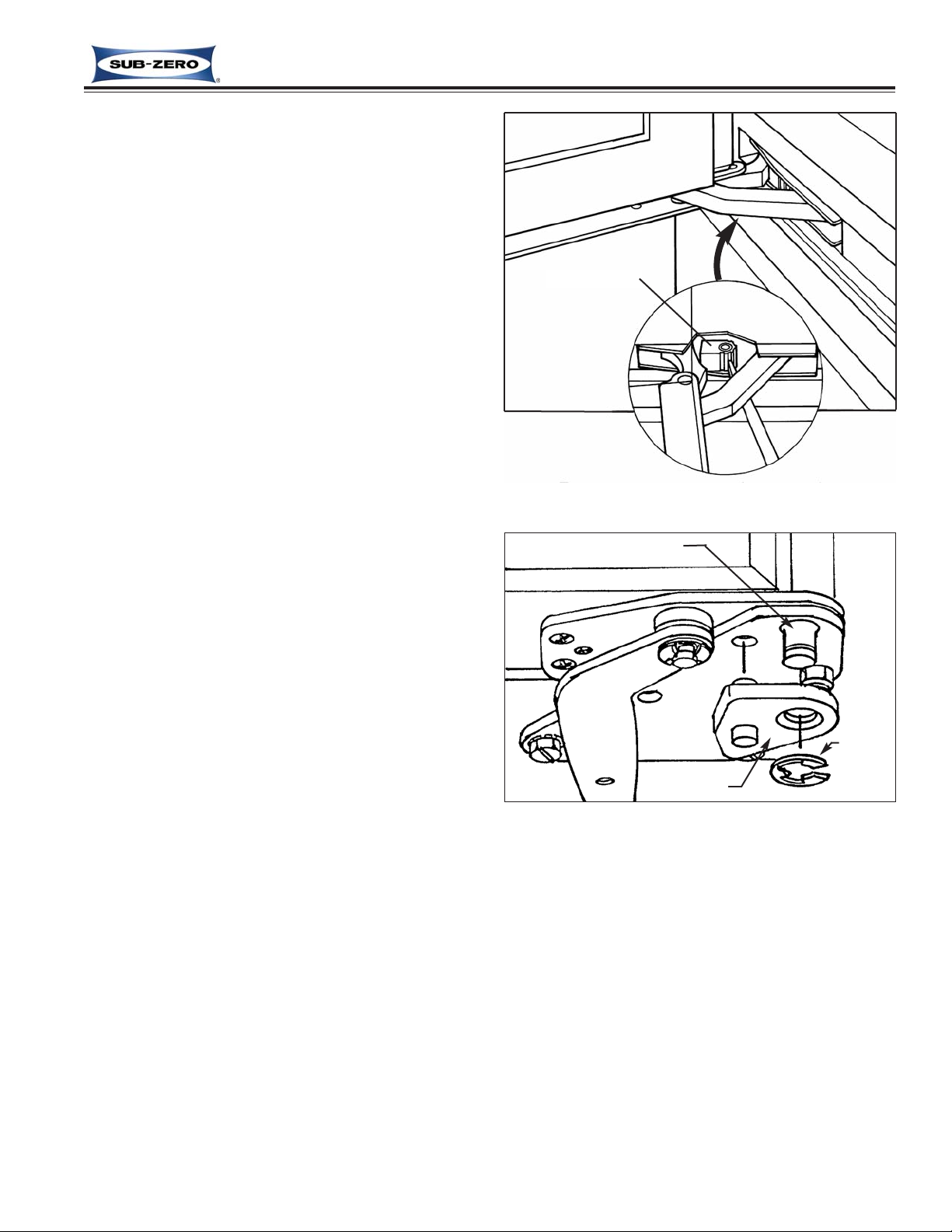

Figure 2-16. Door / Top Door Hinge Adjustment

Cabinet Hinge

Shipping Screws

Door Adjustment (424-2, 424FS-2)

NOTE: Unit must be level before adjusting door.

NOTE: If 424FS-2 door needs adjusting, stainless steel

wrap must be removed to adjust top cabinet hinge (See

Figure 2-14).

If unit is properly installed, blocked and leveled, it may

still be necessary to adjust door left to right and/or in

and out. Adjustments are performed at top and/or bot-

tom cabinet hinge(s) (See Figure 2-15).

1. Working on only one hinge at a time (top or bottom),

remove and discard two small Phillips head shipping

screws from cabinet hinge before attempting adjust-

ments.

2. Using a 1/8” Allen-wrench, loosen and “re-snug” cab-

inet hinge screws, allowing door adjustment.

3. Adjust door as required.

4. After adjusting door, tighten cabinet hinge screws

and check for proper door seal.

Door and/or Drawer Adjustment (427-2 & 427R-2)

NOTE: Door and/or drawers on models 427-2 & 427R-

2 are non-adjustable. Instead, door and/or drawer pan-

els must be adjusted if there is alignment problems.

Refer to Installation Manual.

NOTE: Unit must be level before adjusting door and/or

drawer panels.

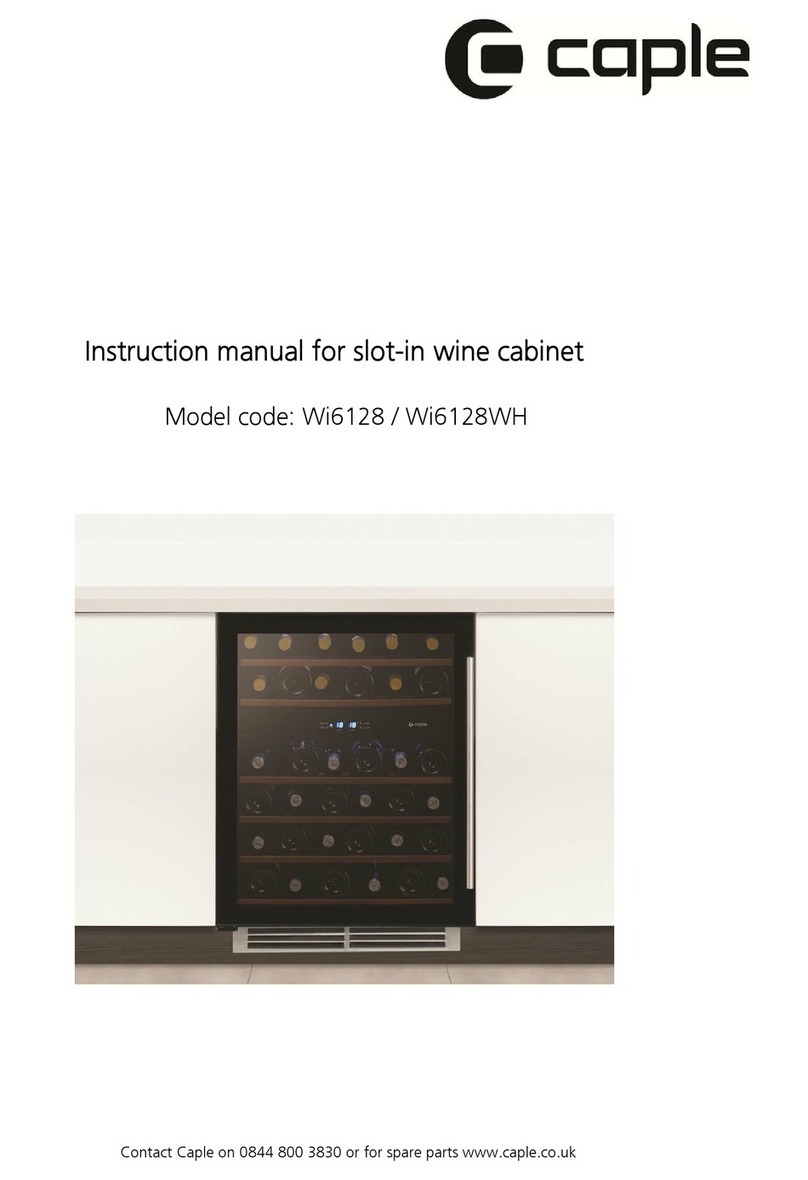

Door Adjustment (430-2)

If unit is properly installed, blocked and leveled, it may

still be necessary to adjust door left to right and/or in

and out. Adjustments are performed at top and/or bot-

tom door hinge(s) (See Figure 2-16).

1. Working on only one hinge at a time (top or bottom),

remove and discard two small Phillips head shipping

screws from door hinge before attempting adjust-

ments.

2. Using a 1/8” Allen-wrench, loosen and “re-snug” door

hinge screws, allowing door adjustment.

3. Adjust door as required.

4. After adjusting door, tighten door hinge screws and

check for proper door seal.

Remove shipping

screws.

Loosen and re-snug

cabinet hinge

screws.

Top

Door Hinge

Door Hinge Screws

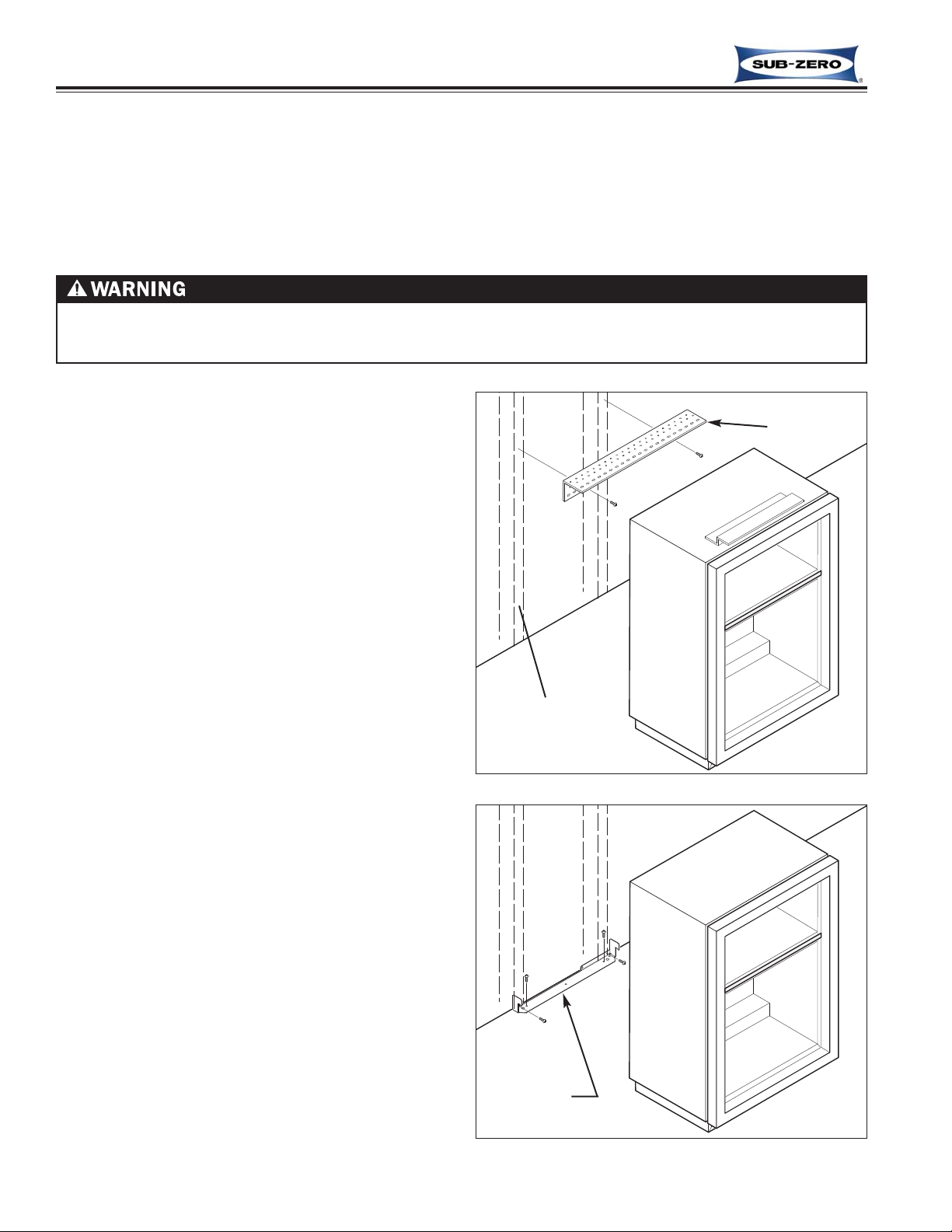

Figure 2-14. Wrap Removal

1. Remove

back brackets. 2. Slide

wrap

forward

& lift up