Foreword

Sumake is a manufacturer and exporter of air

tools since established. We have devote all our

efforts in improving quality and tools’ life. As

well as the noise and vibration of tools. Bring all

of you working efficiences, profits, and enjoy

using the tool is our principle.

Features

This tool is designed to meet an extremely wide

range of materials which need hole drilling by

meansof proper drill bit.

Operator‘s instruction

1. Main Applications

Perfect for hole sawing, valve guide reaming and

knurling, carbon removal, cylinder honing, and

drilling chassis frames and trailer bodies. Ideal

for jobs requiring lots of torque. Tool comes

equipped with dead handle.

2. Cautions for Use

2-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from 5

to 7 bar (70 to 100 psi)

57

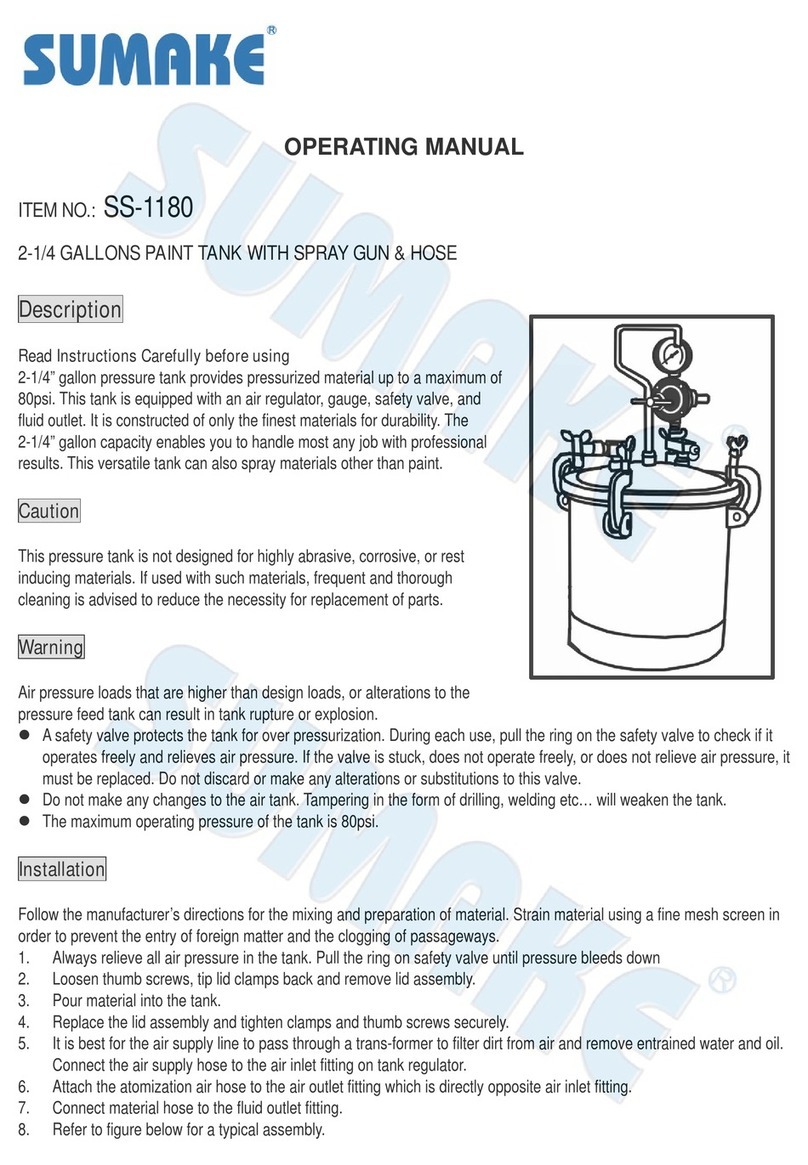

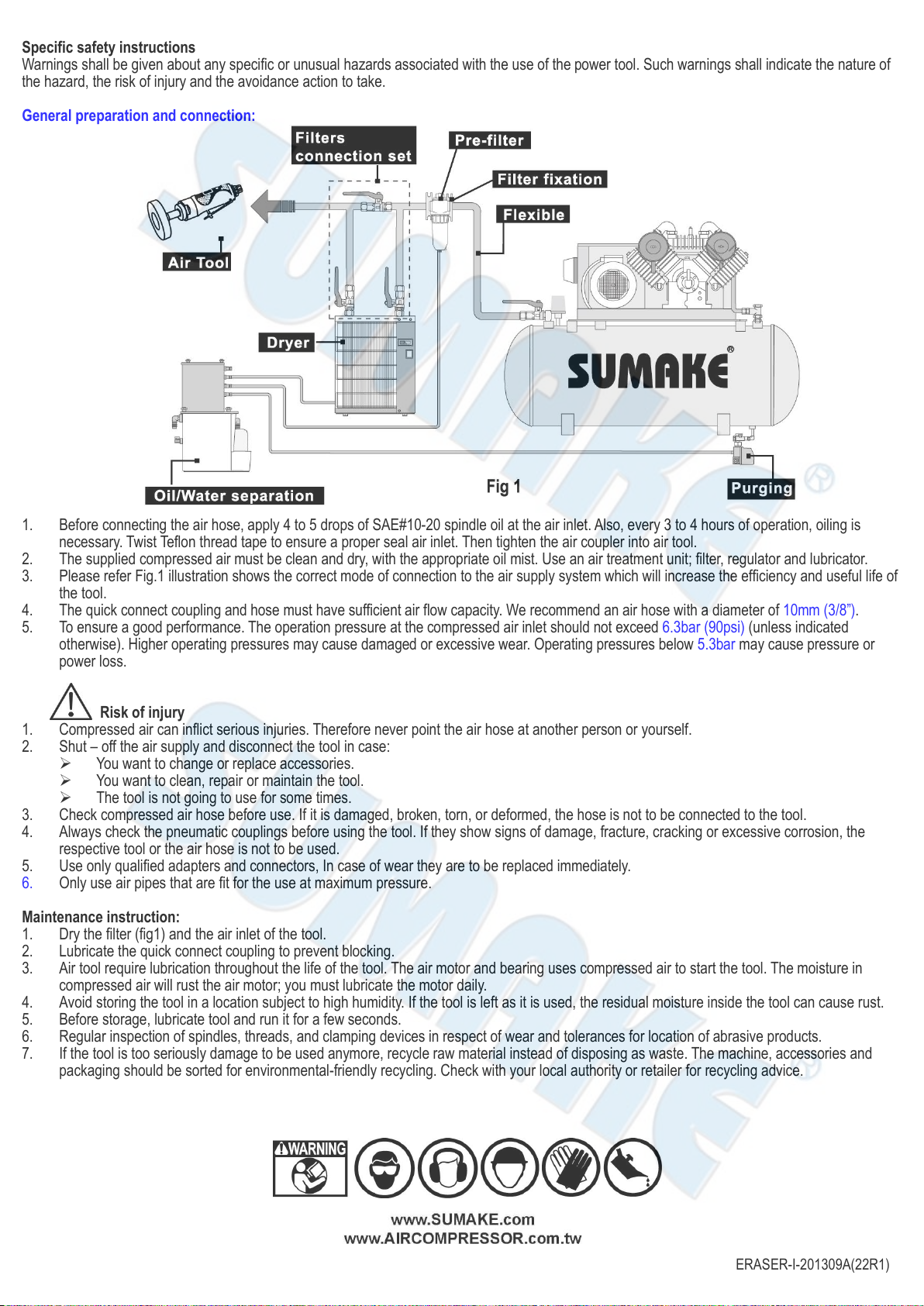

2-2 Air line

Use a 3/8“ air hose between the compressor and

the tool . Compressed air is cooled and its water

content separated, as soon as the air leaves the

compressor.

Tool

Nipple

Coupler Recoil

hose

Leader

hose

Oiler Regulator

Water

separation Air

supply

Drain

daily

A portion of the water content, however, is

condensed in the piping, and can enter the tool

mechanism, and may cause trouble. So, install a

air filter and on oiler between the compressor an

the tool. Use a 3 HP or larger compressor fo

each sander.

2-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This will

revent both moisture and dust within the hos

from entering the tool and causing possible rus

or malfunction. To compensate for unusuall

long hose (over 25 ft), the line pressure should b

increased accordingly.

Drainage

2-4 The approved eye protector, ear-muff,

mouth-muffle, and gloves should be worn whe

operate this tool.

2-5 The working place shall be ventilative.

2-6 Release the on-off device in the case o

energy supply failure.

3. Operation, Adjusting And Replacin

Method

3.1 On-off device

To operate this tool, just push the lever (straigh

type) or trigger (Gun grip type) down. The tool

continuously rotating as one push the levero

trigger down and it might last running for fe

second.

For the sake of safety, put it on a hanger or on

a soft flat pad when not in use.

3.2 Change the drill bit

Disconnect the tool before attemping to put a

drill bit onthis tool. Use the attached chuck key

to untighten the collet, then insert an appropriate

drill bit according to which kind of material that

you will drill hole on as deep as it can reach.

Then tighten the collet again with the chuck key.

3.3 Rotatingdirection

If your tool is reversible, you can change the

rotating direction by switch the direction lever

near the trigger to your desired direction.

Forward, which is marked with an “F”, means

clockwise direction and reverse, which is marked

“R”, indicates the counterclockwise direction.

Before start operating thistool, please make sure

the rotating direction.

3.4 Use a center punch to locate the center on

where you wish to locate the new hole then apply

this tool. It will not only be more precise but also

prevent from the risk caused by the slip of a

rotatingdrill bit.

3.5 If the drill bit penertrate the workpiece, keep

the tool running makes it more easy to remove

this tool fromworkpiece.

4. Maintenance

4-1 Lubrication

Before connecting the hose , apply 4 or 5 drops

of #60 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or

malfunction. If a thicker oil is used by accident,

wipe it away immediately. Also, every 3 or 4

hours of operation, oiling is necessary.

4-2 Storage

Avoid storing the tool in a location subject to

high humidity. If the tool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool at

the air inlet with spindle oil and run it for a short

time.

4-3 Disposal

If the tool is too seriously damaged to be used

anymore, drop it in a resource recycling can.

ever drop it into fire.

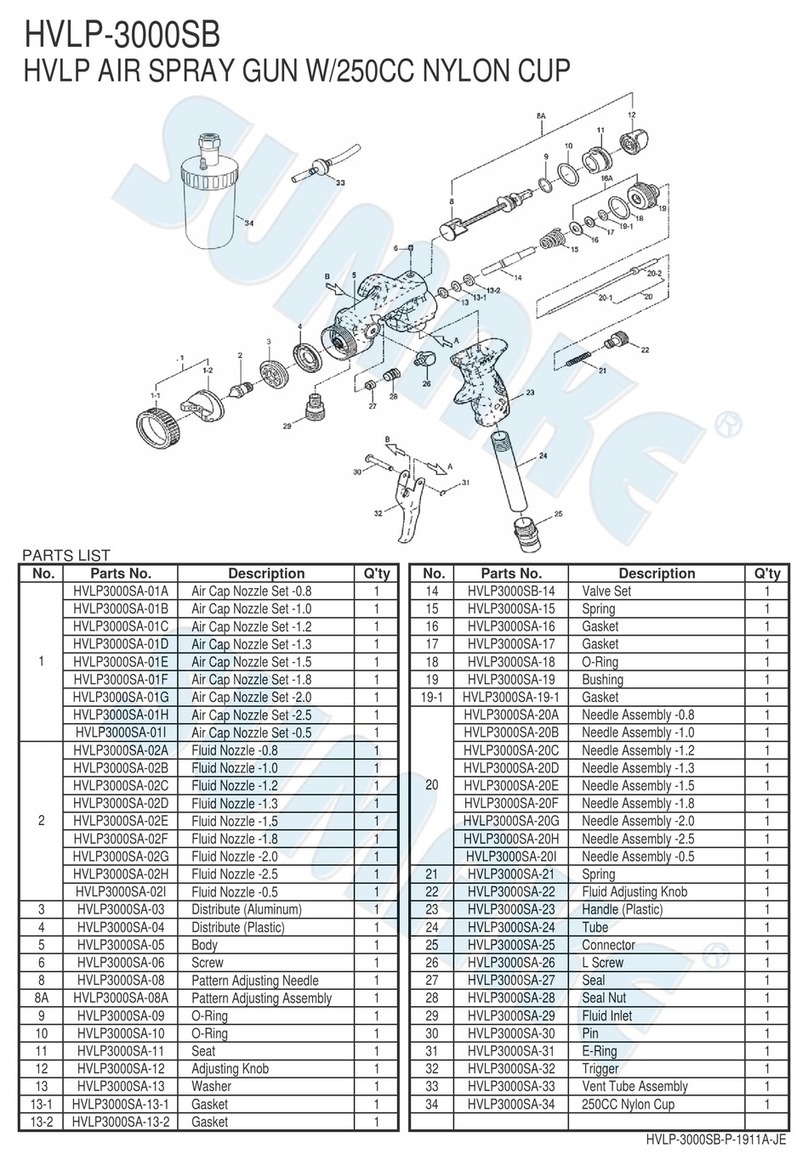

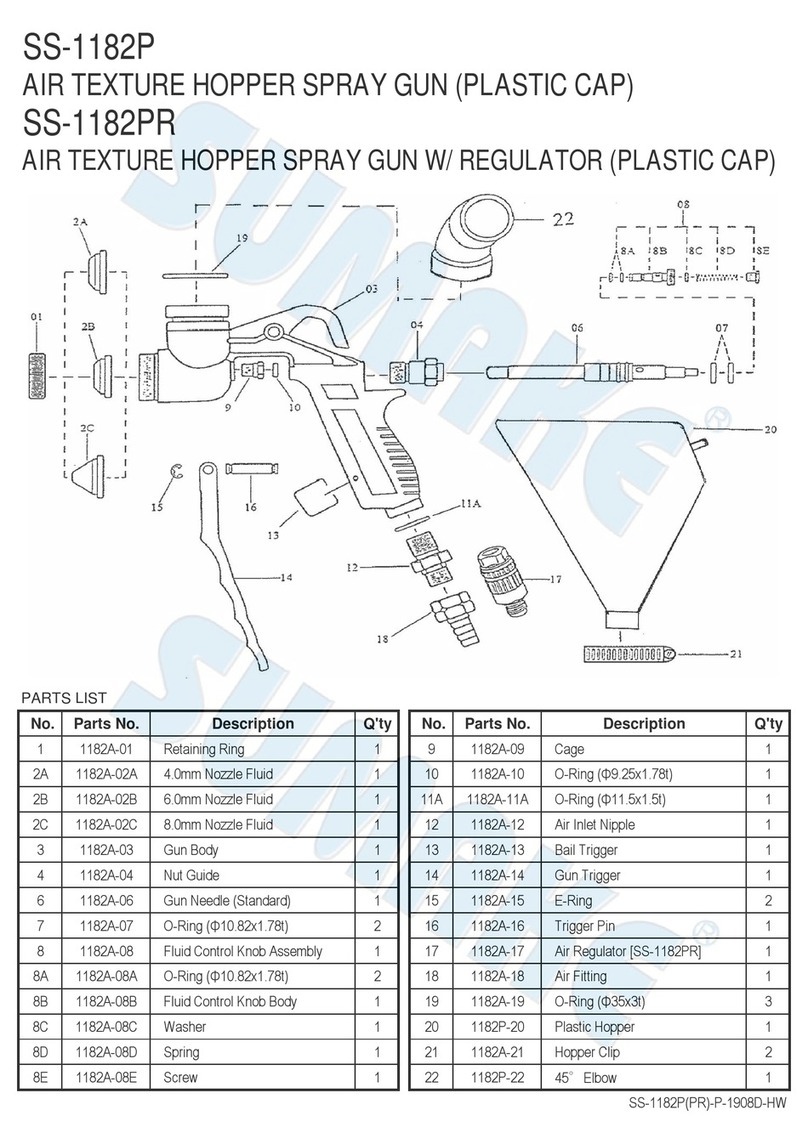

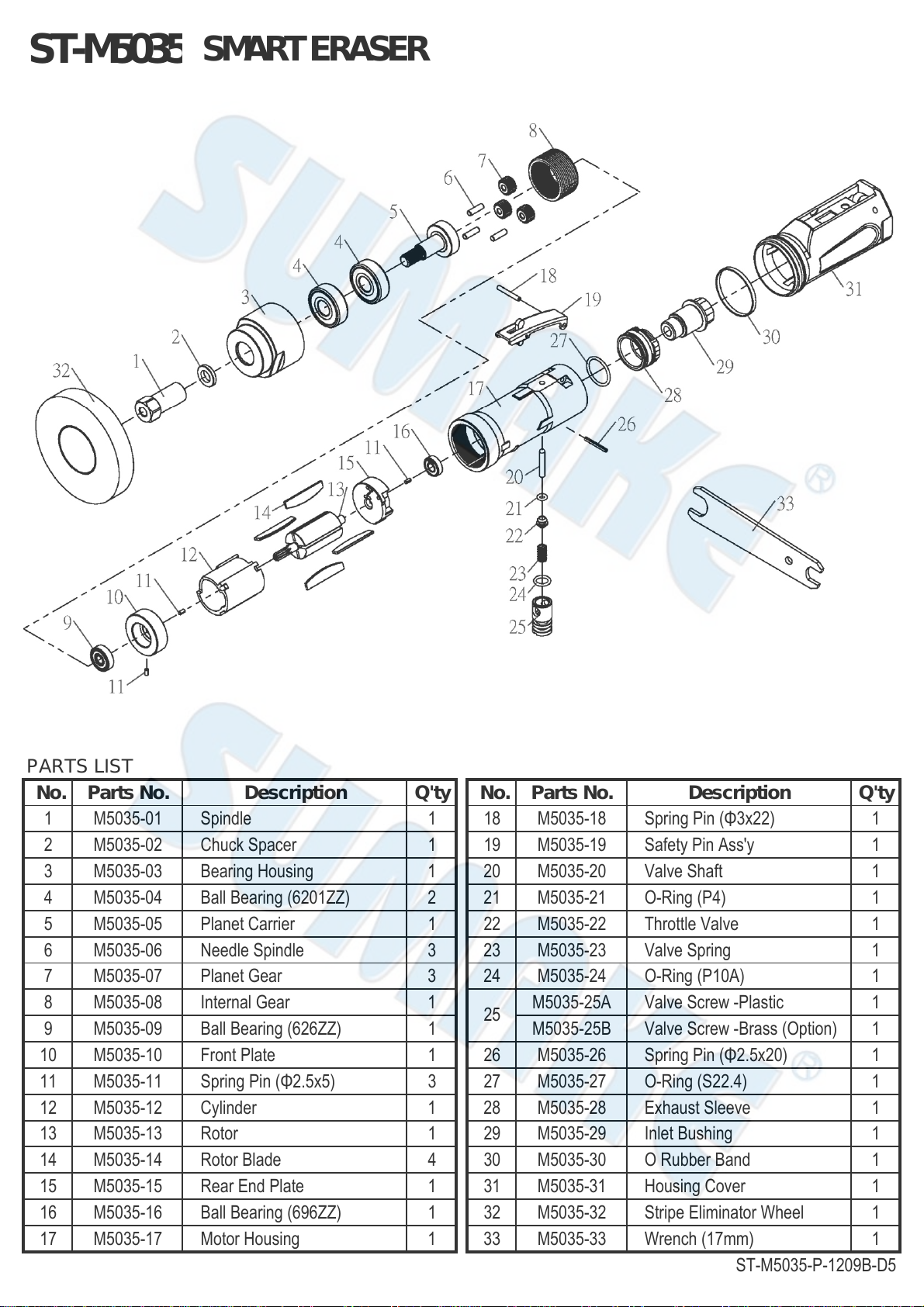

4-4 Ordering service Parts

For further operational and handling information

or for replacement of parts and components,

contact the sale agent from whom you purchase

the tool or the service division of our company.

*In ordering parts and components, give each

part number, name and quantity.

Warning

1. This tool is not insulted for coming int

contact with electric power source.

2. It is forbidden to use this tool in explosiv

atmospheres and do not put any combustibl

material near the workpiece since it emit sparks

when grind with metal material.

3. The drilled trash might be very sharp.Be

careful while deals with this trash.

4. Prevent long hair or loose clothing fro

drawing in while operate this tool.

5. Never carry the tool by hose and beware of

whippingcompressedairhose.

6.Theworkpiece shall be fixed by proper device.

7. Keep your bodywell balanced as you operate

this tool and make sure that no people are within

immediate range of tool operation.

8.Disconnect tool when not in use and attempt

changing the drill bit.

9. Do not link the chuck key to this tool in any

means. The key shall be placed separately from

this tool

ST-M5035-I-1202A-D5