6

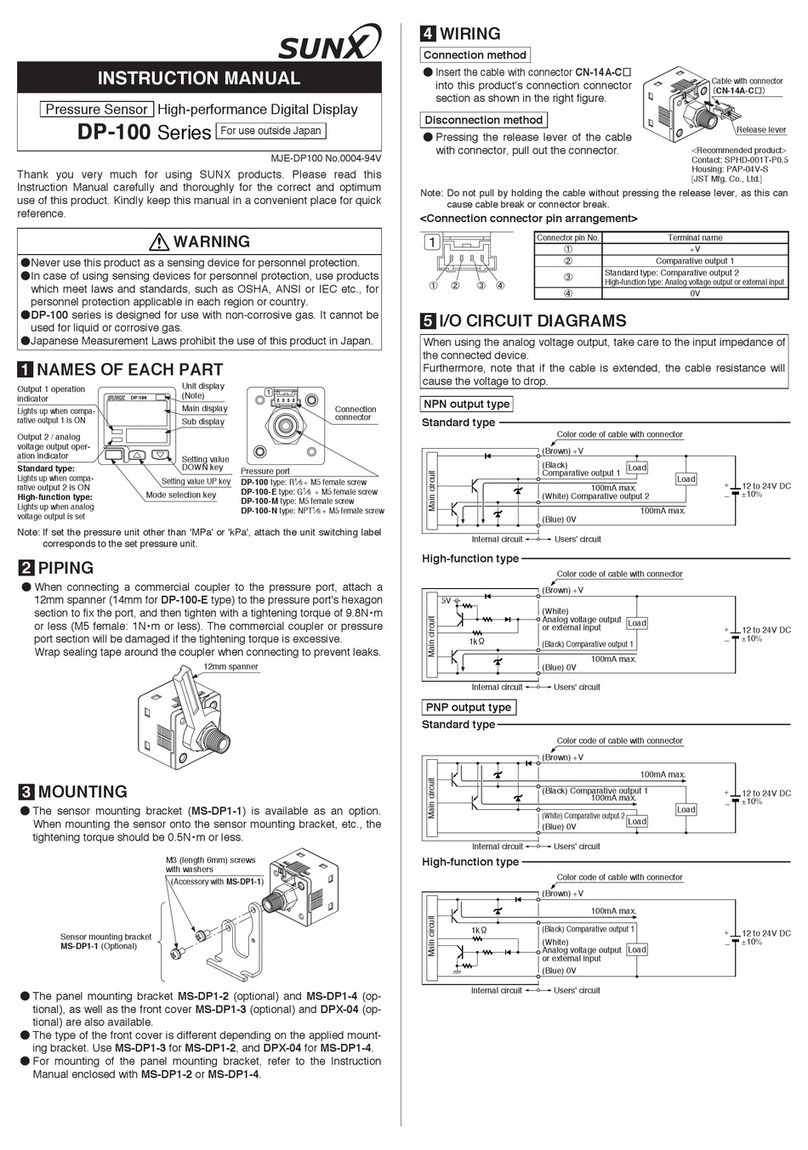

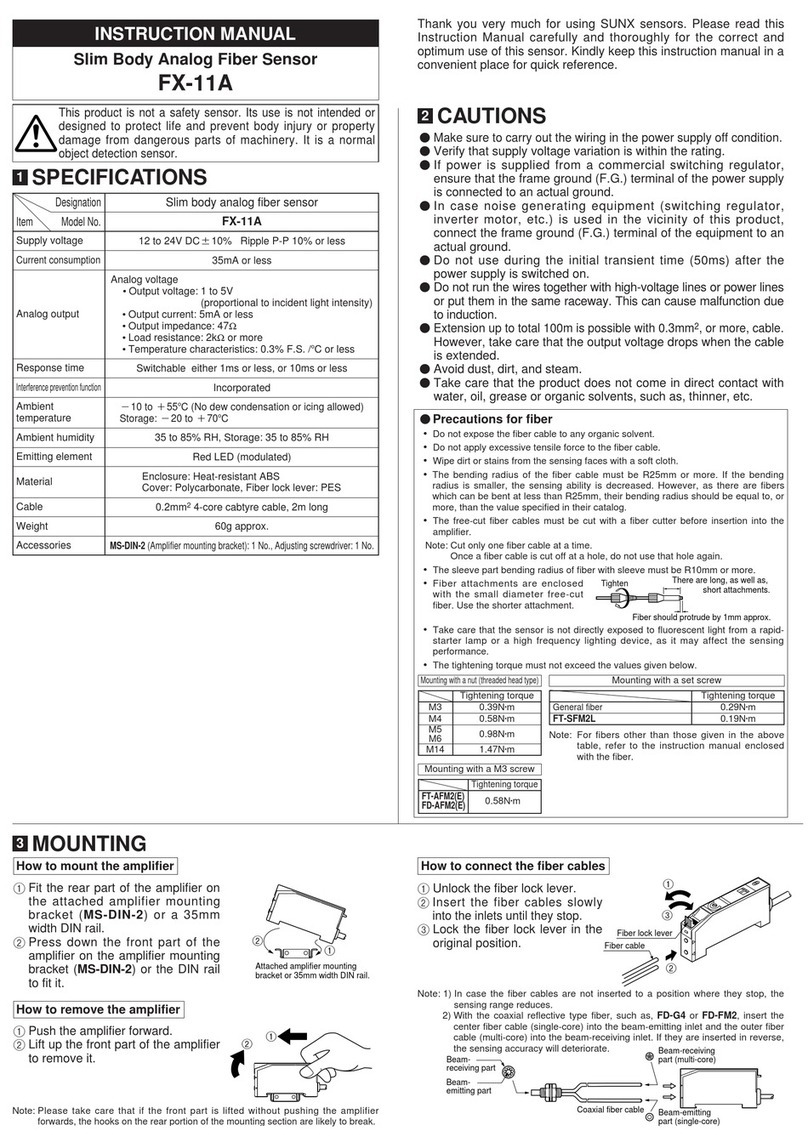

Switching is possible between analog voltage output and external input

Multi-function type is available that allows selection of analog voltage output or external input (auto-reference / remote zero-adjustment).

This is suitable for multi-specification applications.

Auto-reference /

remote zero-adjustment

Low pressure type: 1 to 5 V

High pressure type: 0.6 to 5 V

Comparative output

Analog voltage output

External input

or

ANALOG

lights up

Multi-function type

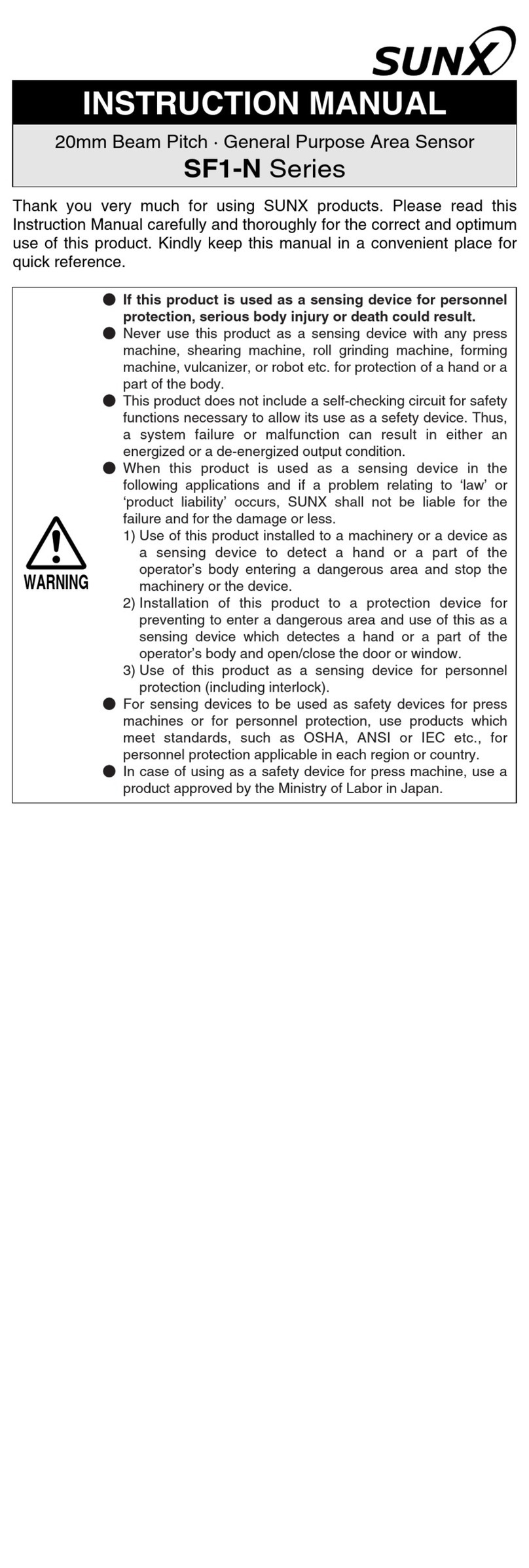

Equipped with auto-reference / remote zero-adjustment functions

More precise pressure management is possible with a minimum of effort

If the reference pressure of the

device changes, the auto-

reference function partially shift

the comparative output

judgment level by the amount

that the reference pressure

shifts, and the remote zero-

adjustment function can reset

the display value to zero via

external input. These functions

are ideal for places where the

reference pressure fluctuates

wildly, or where fine settings are

desired.

Multi-function type

Multi-function type

With auto-reference function applied

20

15

0

5

OK

Comparative output: Window comparator mode

Hi-10, Lo-15

30

Auto-reference input

Sets the absolute threshold level

The display remains at ‘30’ and

only the threshold level is changed.

Threshold level before applying

auto-reference input

Trial 1

25

Time

Pressure

Auto-reference input value

Comparative output: Window comparator mode

Hi-10, Lo-15

Sets the absolute threshold level

With remote zero-adjustment function applied

20

15

0

5

OK

30

Remote zero-adjustment input

Threshold level before applying

remote zero-adjustment input

Threshold level after applying

remote zero-adjustment input

Trial 1

25

Time

Pressure

Displayed when remote zero-

adjustment input is applied

5

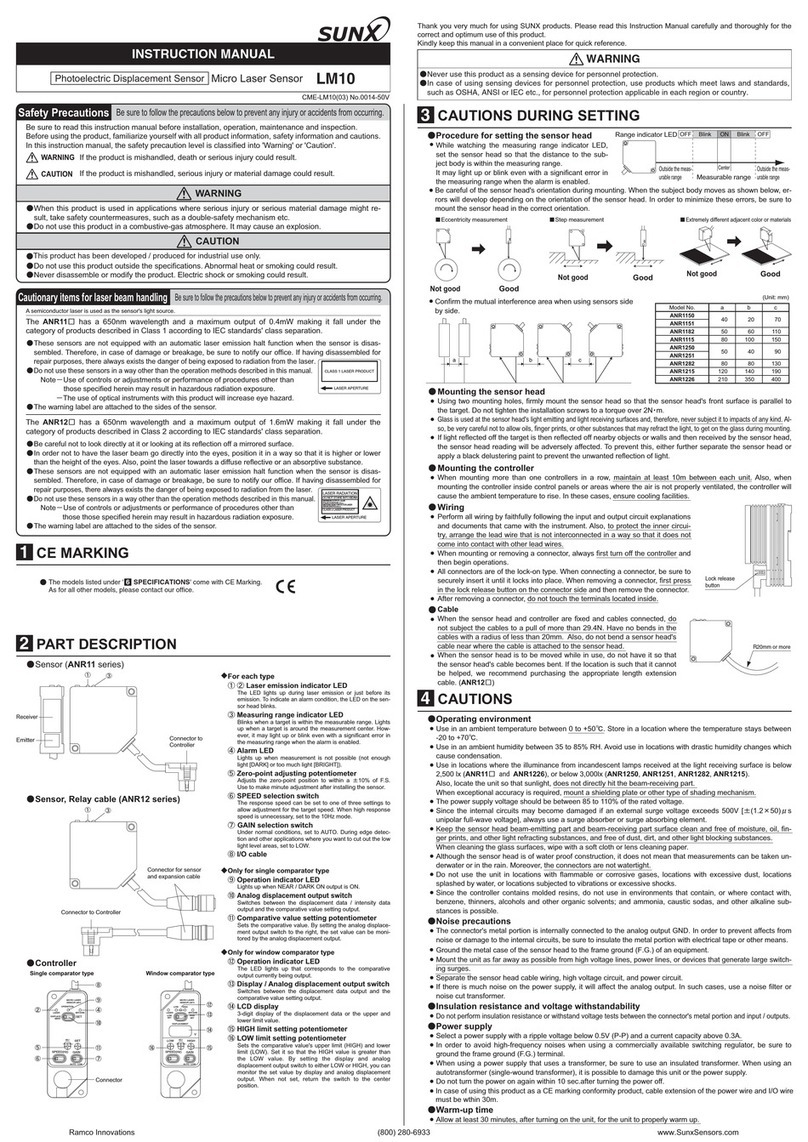

Without auto-reference and remote zero-adjustment functions

0

30

40

OK

NG?

NG?

25

Comparative output: Window comparator mode

Hi-130, Lo-125

Fixed set value

20

Leak threshold level

Variation in the filling pressure

15

Trial 1

Trial 2

Trial 3

Time

Pressure

The display is forced to ‘0’, and only the

filling pressure drop range is displayed.

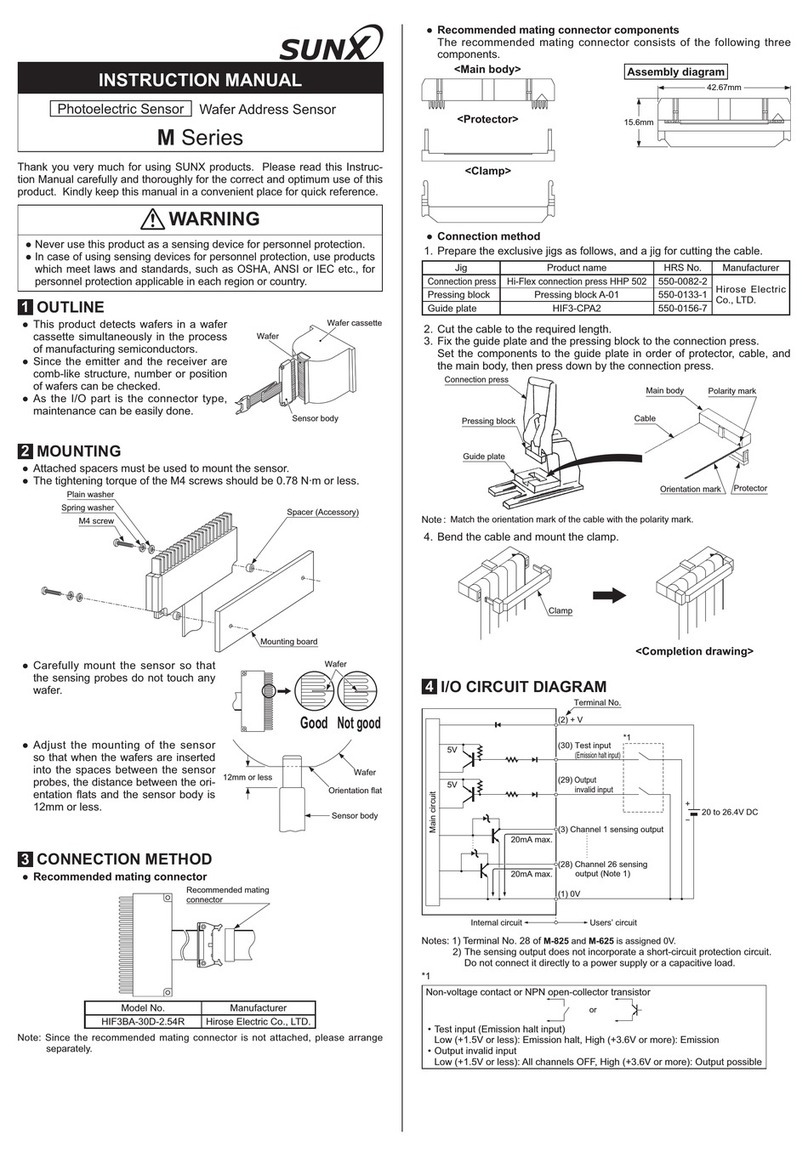

Select

0

Threshold level after applying

auto-reference input

Because the threshold level is fixed for conventional pressure sensors,

changes in the reference pressure result in wrong decisions.

When remote zero-adjustment input is applied, the reference pressure is forced to ‘0’.

If the reference pressure changes to ‘20’ or ‘40’, the remote zero-adjustment input

adjusts the reference pressure to ‘0’ every time the reference pressure changes, so

any variation in the filling pressure can be ignored.

When auto-reference input is applied, the reference pressure ‘30’ is added

to the threshold level. If the reference pressure changes to ‘20’ or ‘40’, the

auto-reference input compensates for this every time by changing the

threshold level, so any variation in the filling pressure can be ignored.