CAUTIONS

2

CME-LX100 No.2137-00

LX-100

Make sure that the power supply is off while wiring.

Take care that wrong wiring will damage the sensor.

Verify that the supply voltage variation is within the rating.

Take care that if a voltage exceeding the rated range is applied, or if an AC

power supply is directly connected, the sensor may get burnt or damaged.

In case noise generating equipment (switching regulator, inverter mo-

tor, etc.) is used in the vicinity of this product, connect the frame ground

(F.G.) terminal of the equipment to an actual ground.

If power is supplied from a commercial switching regulator, ensure that the frame

ground (F.G.) terminal of the power supply is connected to an actual ground.

Do not use during the initial transient time (0.5 sec.) after the power

supply is switched on.

Take care that short-circuit of the load or wrong wiring may burn or damage the sensor.

Do not run the wires together with high-voltage lines or power lines or put

them in the same raceway. This can cause malfunction due to induction.

Take care that the sensor is not directly exposed to fluorescent light

from a rapid-starter lamp or a high frequency light device.

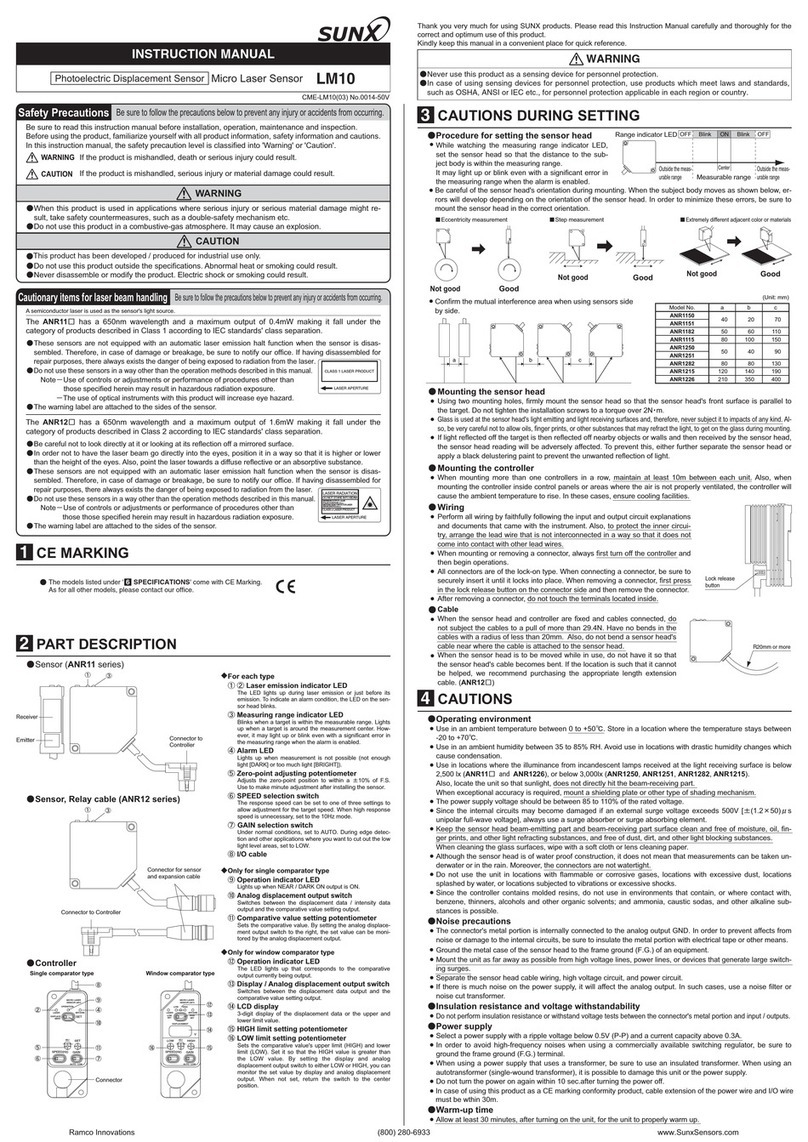

If the surface of the sensing object has a shine,

mount the sensor inclining approx. 10 to 15 degrees

against the sensing object.

Do not touch the lens of the sensor by hand directly. If

the lens becomes dirty, wipe it off with a soft cloth gently.

When the inside lens is steamed up, unscrew the

lens to get rid of the condensation.

For LX-101-غ-Z, b

e sure to use the optional cable with connector.

Extension up to total 100m is possible with 0.3mm2, or more, cable.

However, in order to reduce noise, make the wiring as short as possible.

This sensor is suitable for indoor use only.

Do not use this sensor in places having excessive vapor, dust, etc., or

where it may come in direct contact with water, or corrosive gas.

Take care that the product does not come in direct contact with water,

oil, grease, or organic solvents, such as, thinner, etc.

Make sure that stress by forcible bend or pulling with

76N, or more, force

is not applied directly to the sensor cable joint.

This sensor cannot be used in an environment containing inflammable

or explosive gases.

Never disassemble or modify the sensor.

INSTRUCTION MANUAL

Digital Mark Sensor

Photoelectric Sensor

Thank you very much for using SUNX products. Please read this Instruction

Manual carefully and thoroughly for the correct and optimum use of this

product. Kindly keep this manual in a convenient place for quick reference.

Never use this product as a sensing device for personnel

protection.

In case of using sensing devices for personnel protec-

tion, use products which meet standards, such as

OSHA, ANSI or IEC etc., for personnel protection ap-

plicable in each region or country.

٨

٨

WARNIN

G

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

10䌾15㫦

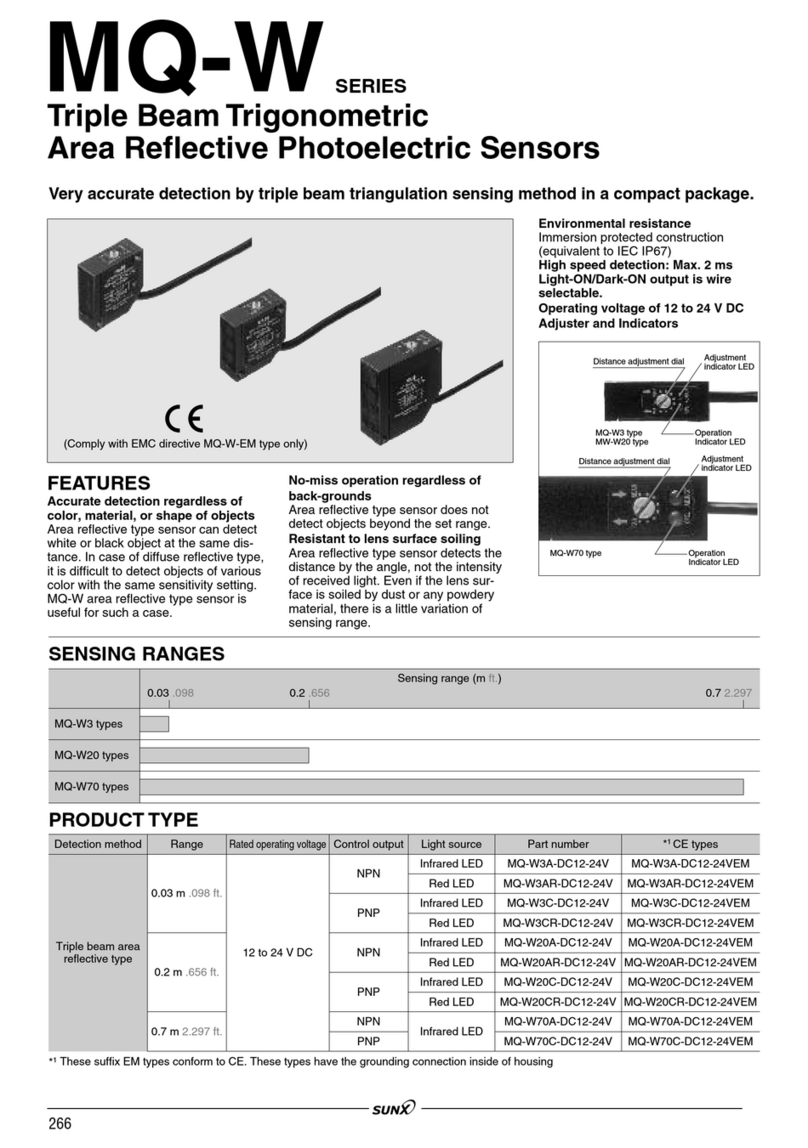

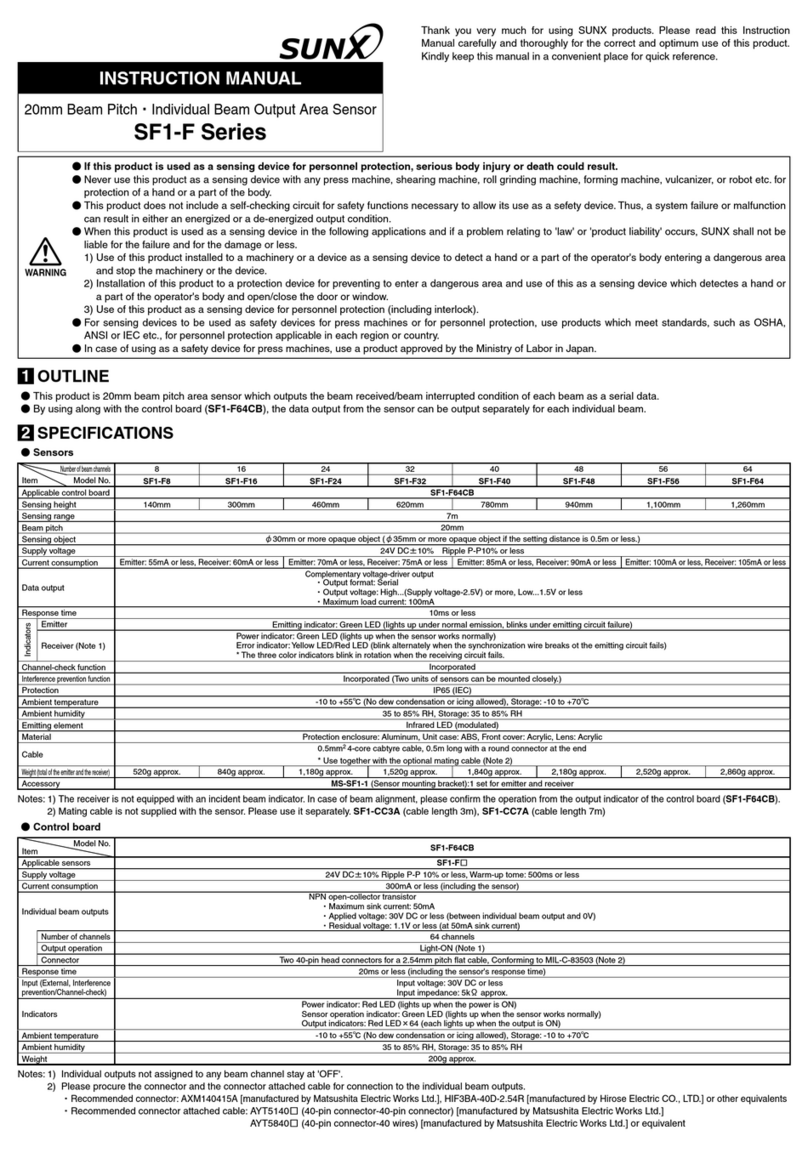

SPECIFICATIONS

1

Notes: 1)

2)

The connector type LX-101غ-Z is 100mA.

The connecting cable is not supplied as an accessory for the connector type

LX-101غ-Z. Make sure to use the optional cables with connector below:

CN-24B-C2 (Straight type, 4-core, Cable length: 2m) CN-24BL-C2 (Elbow type, 4-core, Cable length: 2m)

CN-24B-C5 (Straight type, 4-core, Cable length: 5m) CN-24BL-C5 (Elbow type, 4-core, Cable length: 5m)

Max. sink current: 50mA

Applied voltage: 30V DC or less

(between output 2 and 0V)

Residual voltage: 1.5V or less

(at 50mA sink current)

NPN

open-collector transistor

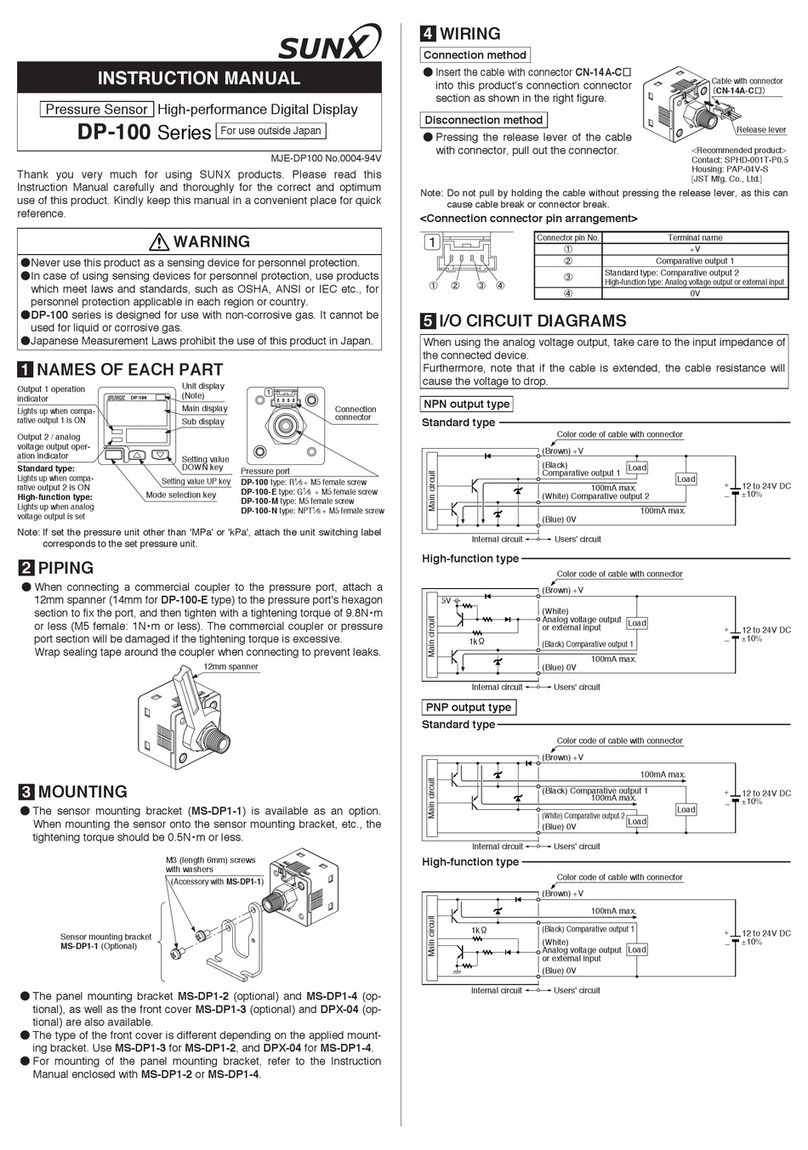

<NPN output type>

Max. source current: 50mA

Applied voltage: 30V DC or less

(between output 2 and +V)

Residual voltage: 1.5V or less

(at 50mA source current)

PNP

open-collector transistor

<PNP output type>

Incorporated

Incorporated OFF-delay timer/ON-delay timer, switchable either effective or ineffective

'RUN': Green LED, 'TEACH', 'ADJ', 'COLOR', 'TIMER', 'PRO': Yellow LED

MODE indicator

Response time

Operation indicator

Mark mode: 2-level teaching/Full-auto teaching, Color mode: 1-level teaching

Sensitivity setting Incorporated

IP67 (IEC)

4 digits red LED display

Orange LED (lights up when output 1 is ON)

Mark mode: 45Ǵs or less, Color mode: 150Ǵsorless

Digital display

Timer function

Protection

Fine sensitivity adjustment function

Material

Ambient temperature

120g approx. 55g approx.

Weight

Enclosure: PBT, Display: Polycarbonate, Operation buttons: Silicon rubber, Lens: Glass

0.2mm

2

5-core cabtyre cable, 2m long

Cable

35 to 85% RH, Storage: 35 to 85% RH

-10 to +55(No dew condensation or icing allowed), Storage: -20 to +70

Ambient humidity Red/green/blue LEDEmitting element

Current consumption

Teaching input

Supply voltage

Setting distance

Output 1

(OUT)

Item

Normal mode: 750mW or less (Current consumption 30mA or less at 24V supply voltage)

EOC mode: 600mW or less (Current consumption 25mA or less at 24V supply voltage)

12 to 24V DC+/-10%˴Ripple P-P10% or less

10mm r3mm

Low (ON): 0 to 2V DC

Source current 0.5mA or less

Input impedance 10kǡapprox.

High (OFF): 5V to +V DC, or open

<NPN output type>

High (ON): 5V to +V DC

Sink current 0.5mA or less

Input impedance 10kǡapprox.

Low (OFF): 0 to 0.6V DC, or open

<PNP output type>

Max. sink current: 50mA (Note 1)

Applied voltage: 30V DC or less

(between output 1 and 0V)

Residual voltage: 1.5V or less

㨇at 50mA (Note 1) sink current㨉

NPN open-collector transistor

<NPN output type>

Max. source current: 50mA (Note 1)

Applied voltage: 30V DC or less

(between output 1 and +V)

Residual voltage: 1.5V or less

㨇at 50mA (Note 1) source current㨉

<PNP output type>

PNP open-collector transistor

LX-101-P-ZLX-101-P

LX-101-ZLX-101 Connector typeCable type

NPN output

PNP output

Type

Model

No.

Mark mode: Light-ON/Dark-ON Auto-setting method on teaching,

Color mode: Coincidence-ON/

Non-coincidence-ON

Output operation

Incorporated

Short-circuit protection

Inverted operation of the output 1

Output operation

Short-circuit protection

Output 2 (Inversion output)

(OUT)

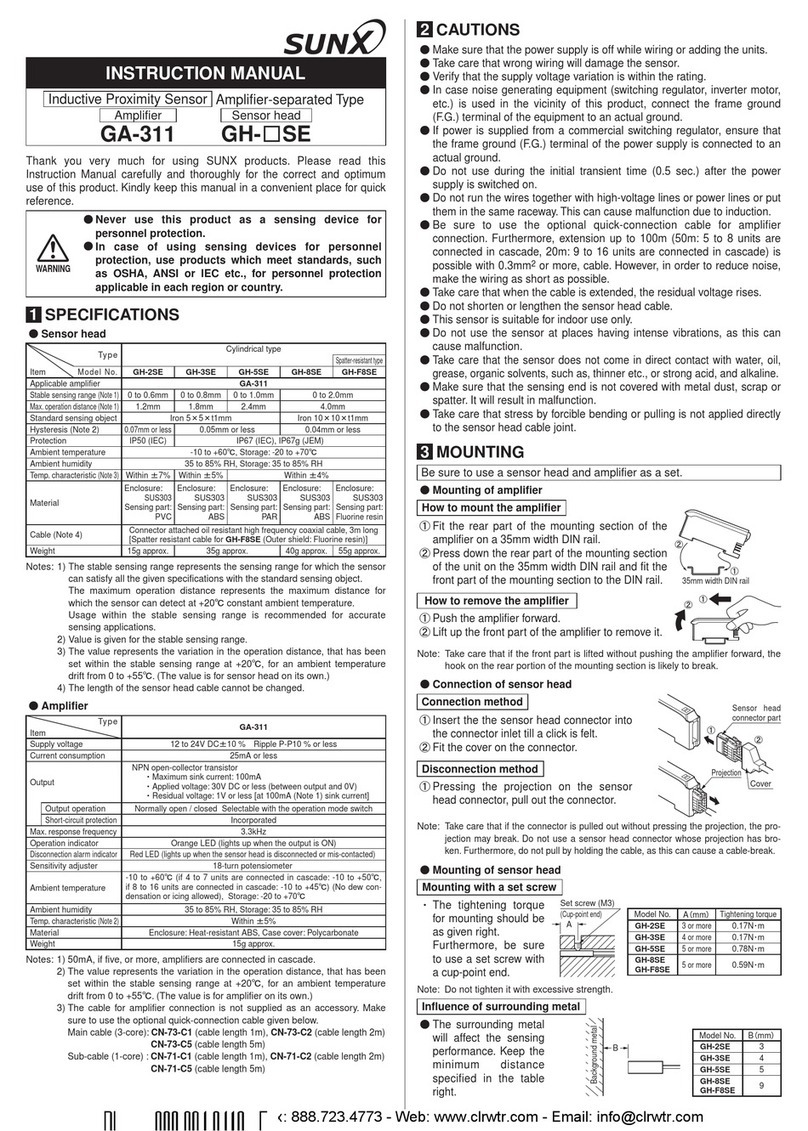

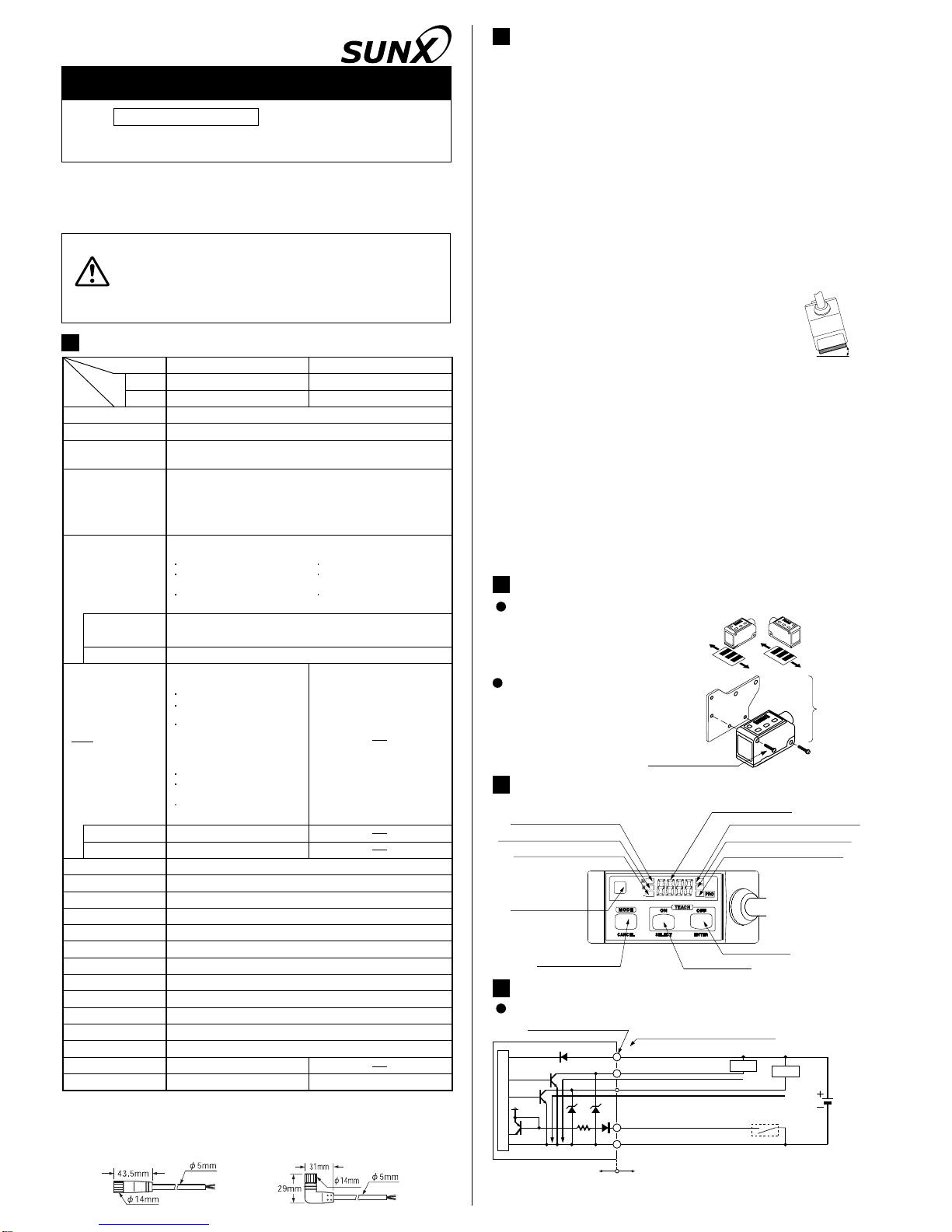

MOUNTING

3

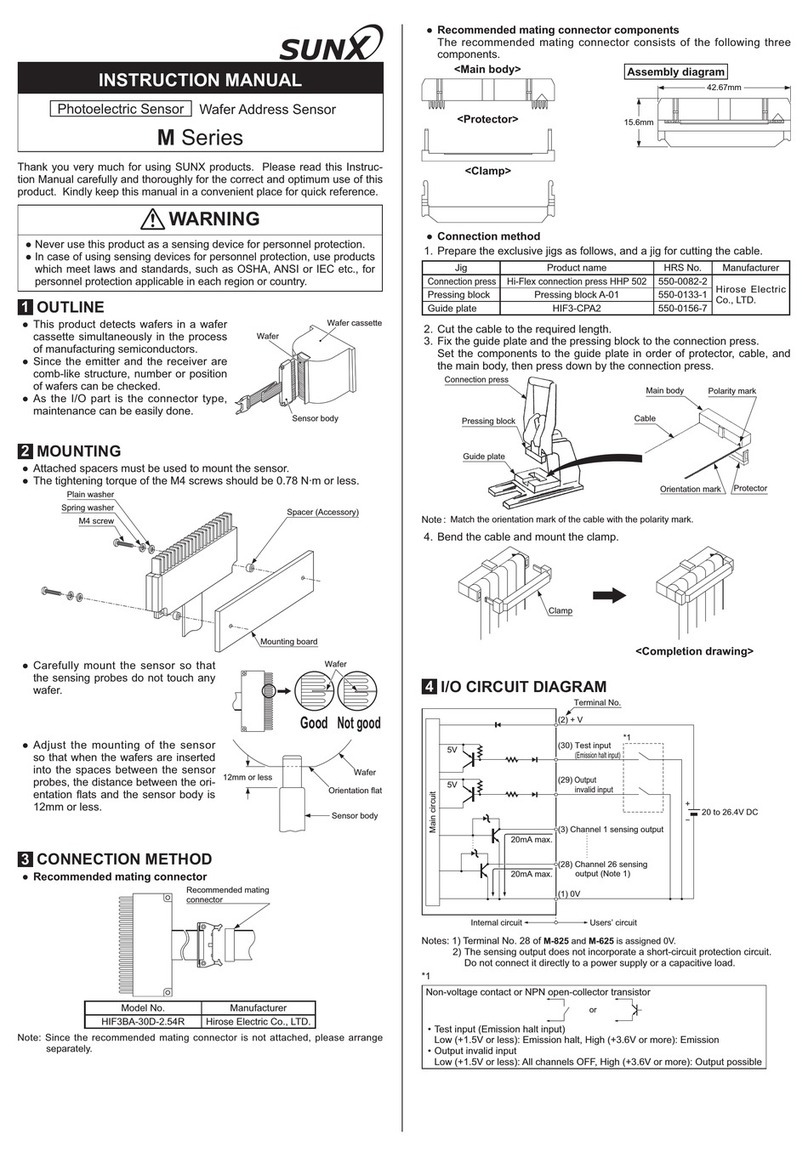

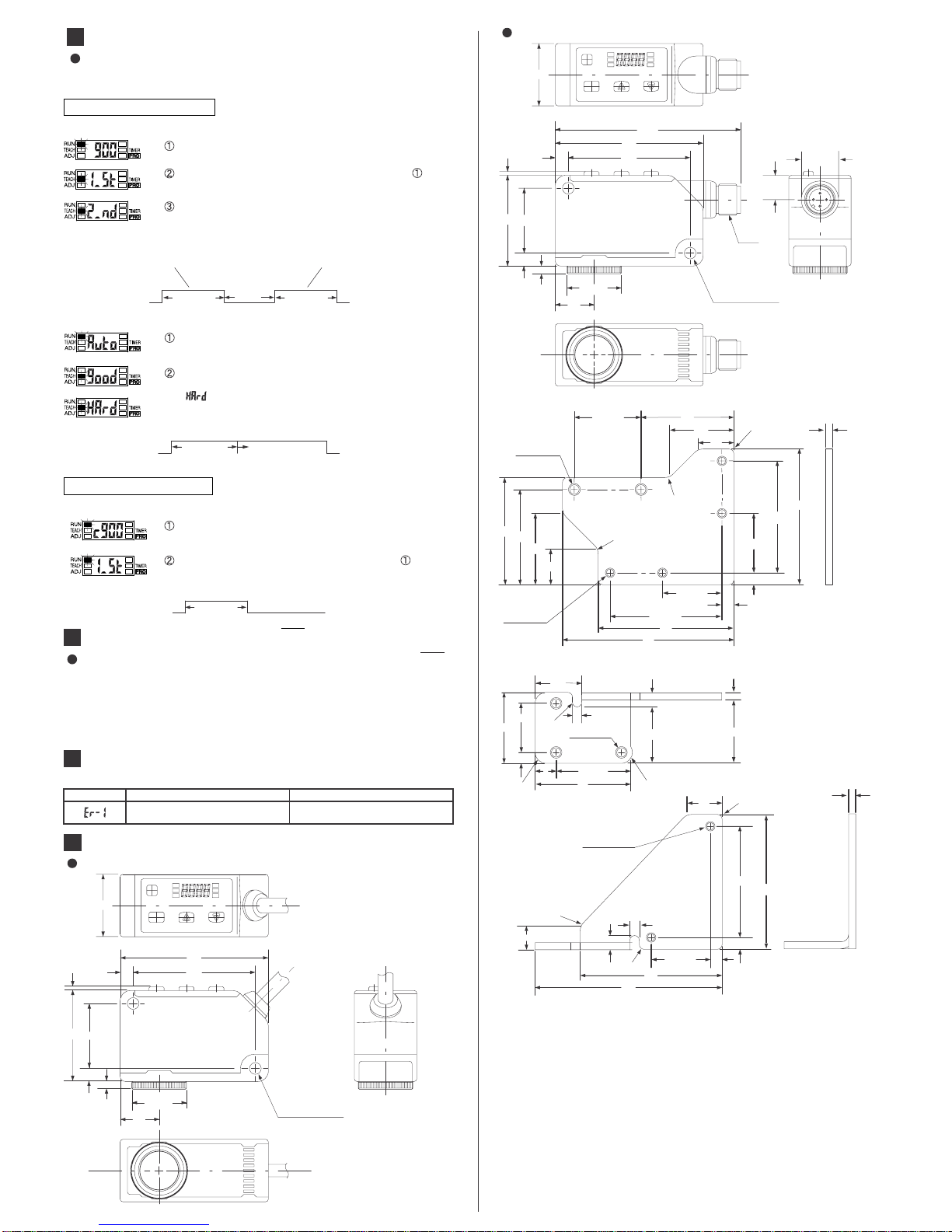

PART DESCRIPTION

4

I/O CIRCUIT DIAGRAMS

5

Notes: 1)

2)

The output 2 is not incorporated to connector type LX-101غ-Z.

The current of the connector type LX-101غ-Z is 100mA.

NPN output type

D2

10kǡ

D1

1

4

12 to 24V DC

r10%

Terminal No. of Connector Color code of cable type/cable with

connector

(Brown) +V

(Black) Output 1

50mA max. (Note 2)

50mA max. (Note 2)

(White) Output 2

(Note 1)

3

Z

D1

Z

D2

(Blue) 0V

Tr1

Tr2

(Pink) Teaching input *1

5V

2

Sensor circuit

Users' circuitInternal circuit

Load Load

Do not make the

sensor detect an

object in this di-

rection because it

may cause unsta-

ble operation.

Good

No good

Care must be taken regarding the

sensor mounting directrion with

respect to the object's direction of

movement.

The tightening torque should be

0.8N䊶m or less.

Sensor mounting

bracket

MS-LX-1

(Optional)

M4 screw with washers

COLOR

TIMER

OPE.

RUN

ADJ.

TEACH

Operation indicator

(Orange)

MODE/CANCEL key OFF/ENTER key

ON/SELECT key

MODE indicator / RUN (Green)

MODE indicator / ADJ (Yellow)

MODE indicator / TEACH (Yellow)

MODE indicator /

TIMER

(Yellow)

MODE indicator /

COLOR (Yellow)

MODE indicator /

PRO

(Yellow)

Digital display (Red)