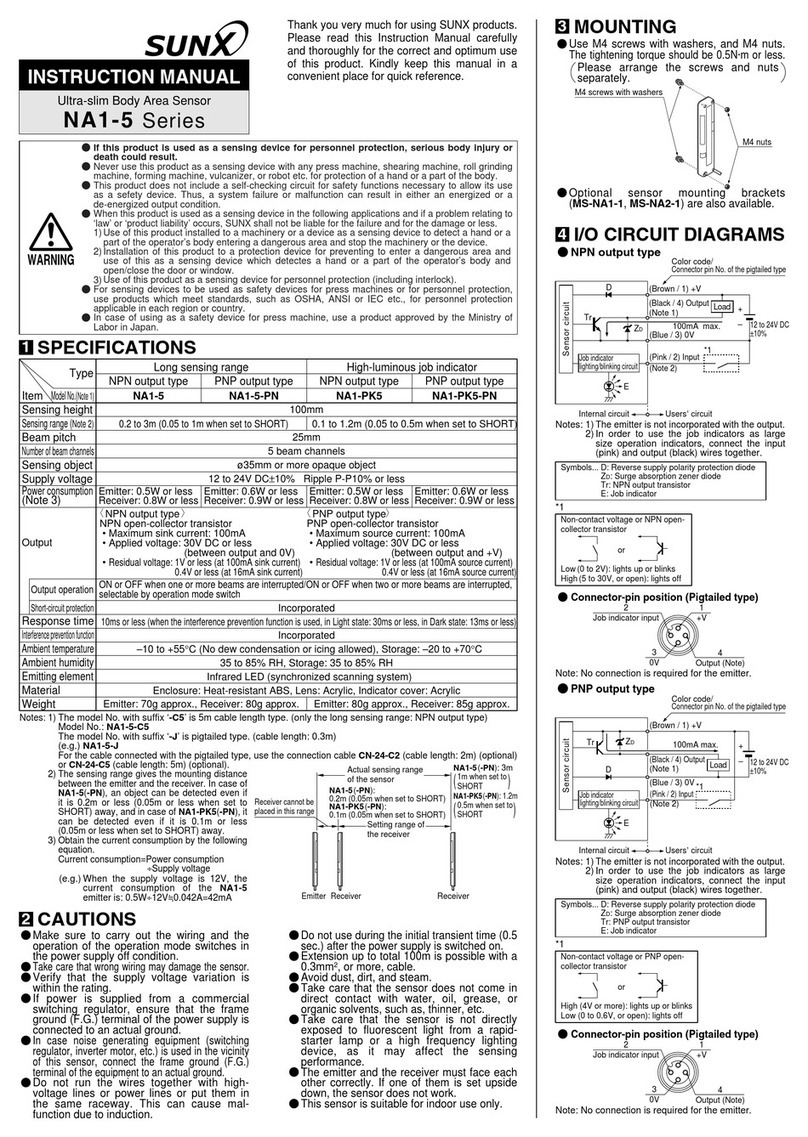

Sensing height

Sensing range

Beam pitch

Beam spread angle

Sensing object

Supply voltage

Current consumption

Outputs(OSSD 1, OSSD 2)

(Note 1)

Output operation

Short-circuit protection

Response time

Emitter

Receiver

Test input function

Interference prevention function

Protection

Ambient temperature

Ambient humidity

Ambient illuminance

EMC

Voltage withstandability

Insulation resistance

Vibration resistance

Shock resistance

Emitting element

Material

Cable

Cable extension

Weight

Accessories

220mm 300mm 380mm 460mm 540mm 620mm 700mm 780mm 940mm 1,100mm1,260mm1,420mm1,580mm

0.3 to 10m

20mm

2.5°or less [for sensing range exceeding 3m (conforming to IEC 61496-2)]

"30mm or more opaque object

24V DC15%

200mA or less

<PNP output equivalent type>

Semiconductor output (PNP output equivalent) 2 outputs

•Maximum source current: 300mA

•Applied voltage: same as supply voltage

•Residual voltage: 2.5V or less (at 300mA source current)

ON when all beams are received/OFF when one or more beams are interrupted

(It also turns OFF in case of any abnormality in the sensor or the synchronization signal.)

Incorporated

ONnOFF: 15ms or less, OFFnON: 20ms or less

Emitting indicator: Green LED (lights up under normal emission)

Emission stop indicator: Orange LED (lights up when emission stops)

Fault indicator: Yellow LED (lights up or blinks if the sensor fails)

OSSD ON indicator: Green LED (lights up when OSSDs are ON)

OSSD OFF indicator: Red LED (lights up when OSSDs are OFF)

Incident beam indicator: Green/Red LED [lights up in red with intensity proportional to the incident light intensity for reference

channel (second channel from cable side), lights up in green when all beams are received]

Fault indicator: Yellow LED (lights up or blinks if the sensor fails)

Incorporated

Series connection: 4 sets max., however total 192 beam channels max.

Incorporated Parallel connection: 4 sets max., however total 192 beam channels max.

Series and parallel mixed connection: 12 sets max., however total 192 beam channels max.

IP65 (IEC)

10 to55°C (No dew condensation or icing allowed), Storage:25 to70°C

30 to 85% RH, Storage: 30 to 95% RH

Sunlight: 20,000?x at the light-receiving face, Incandescent light: 3,500?x at the light-receiving face

Emission: EN50081-2, Immunity: EN50082-2 and IEC 61496-1

1,000V AC for one min. between all supply terminals connected together and enclosure

20MΩ, or more, with 500V DC megger between all supply terminals connected together and enclosure

10 to 55Hz frequency, 0.75mm amplitude in X, Y and Z directions for two hours each

300m/s2acceleration (30G approx.) in X, Y and Z directions for three times each

Infrared LED (Emission wavelength: 870nm)

Enclosure: Aluminum, Cap: ABS

8-core (0.3mm24-core, 0.2mm24-core) shielded cable, 0.5m long, with a connector at the end

mUse together with the optional mating cable

Extension up to total 27m is possible, for both emitter and receiver, with optional mating cables.

1.1kg approx. 1.3kg approx. 1.5kg approx. 1.7klg approx. 1.9kg approx. 2.2kg approx. 2.4kg approx. 2.6kg approx. 3.1kg approx. 3.5kg approx. 4.0kg approx. 4.4kg approx. 4.9kg approx.

MS-SF2-1 (Sensor mounting bracket): 1 set, MS-SF2-2 (Intermediate supporting bracket): (Note 2), SF2-EH-TR (Test rod): 1 No.

12 16 20 24 28 32 36 40 48 56 64 72 80

SF2-EH12 SF2-EH16 SF2-EH20 SF2-EH24 SF2-EH28 SF2-EH32 SF2-EH36 SF2-EH40 SF2-EH48 SF2-EH56 SF2-EH64 SF2-EH72 SF2-EH80

SF2-EH12-N SF2-EH16-N SF2-EH20-N SF2-EH24-N SF2-EH28-N SF2-EH32-N SF2-EH36-N SF2-EH40-N SF2-EH48-N SF2-EH56-N SF2-EH64-N SF2-EH72-N SF2-EH80-N

SF2-EH

5

SPECIFICATIONS

Notes: 1) OSSD stands for ‘Output Signal Switching Device’.

Notes: 2) MS-SF2-2 (intermediate supporting bracket) is attached with sensors having 24, or more, beam channels.

The number of attached intermediate supporting brackets is different depending on the sensor as follows.

SF2-EH24(-N), SF2-EH28(-N), SF2-EH32(-N), SF2-EH36(-N), SF2-EH40(-N), SF2-EH48(-N), SF2-EH56(-N): 1 set

SF2-EH64(-N), SF2-EH72(-N), SF2-EH80(-N): 2 sets

Model

No.

Item

PNP output equivalent type

NPN output equivalent type

<NPN output equivalent type>

Semiconductor output (NPN output equivalent) 2 outputs

•Maximum sink current: 300mA

•Applied voltage: same as supply voltage

•Residual voltage: 2V or less (at 300mA sink current)

Indicators

Environmental resistance

Number of beam

channels

( )